Active Member

|

[China]

Address: No. 812-813, Building C2, Yongsheng Commercial Plaza, 222 Labor East Road, Yuhua District, Changsha City, Hunan, China

Contact name:Florence Tang

Hunan Fushun Metal Co., Ltd. |

|

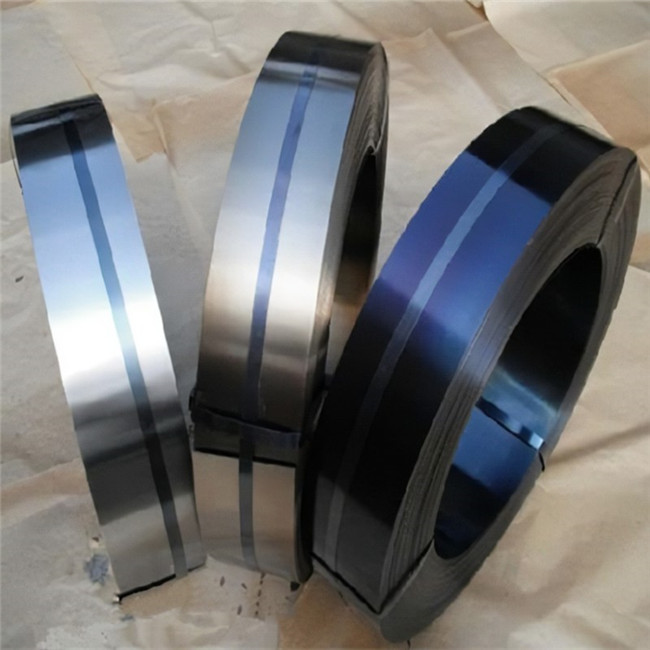

Grade : 54SiCr6

Number: 1.7102

Classification: Alloy special steel

Standard:

EN 10089: 2002 Hot rolled steels for quenched and tempered springs. Technical delivery conditions

Dimensions and tolerances

Thickness: 0.1 to 6 mm; Tolerances: +/- 0.008 to 0.11 mm

Width: 8 to 400 mm; Tolerances: +/- 0.15 to 0.60

Our Advantage

1. Precise thickness, uniform hardness. Bright surface, smooth

edge.

2. High flatness of board surface, high performance after multiple

bending.

3. No cracking after stamping, and the quality is stable. And we

provide Self-Inspection Reports and Raw-Material Test Certificates.

4. Professional anti-rust protective packaging. On time delivery,

competitive price.

5. Large stock available, no MOQ requirement

| DIN 1.7102 | AFNOR 54SiCr6 | BS 685 A57 | UNI 54SiCr6 | AISI 9254 | SAE 9254 |

| JIS SUP12 | EN 54SiCr6 | EN 1.7102 | GOST 60S2ChA | UNS G92540 |

| C | Si | Mn | P | S | Cr | - |

| 0.51 - 0.59 | 1.2 - 1.6 | 0.5 - 0.8 | max 0.025 | max 0.025 | 0.5 - 0.8 | Cu+10Sn < 0.6 |

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Density (×1000 kg/m3) | 7.7-8.03 | 25 | |

| Poisson's Ratio | 0.27-0.30 | 25 | |

| Elastic Modulus (GPa) | 190-210 | 25 | |

| Tensile Strength (Mpa) | 1158 | 25 | oil quenched, fine grained, tempered at 425°C |

| Yield Strength (Mpa) | 1034 | ||

| Elongation (%) | 15 | ||

| Reduction in Area (%) | 53 | ||

| Hardness (HB) | 335 | 25 | oil quenched, fine grained, tempered at 425°C |

Soft Annealing:

Heat to 640-680C, cool slowly in furnace. This will produce a

maximum Brinell hardness of 310.

Normalizing:

Temperature: 850-880C, air.

Hardening:

Harden from a temperature of 840-870C followed by oil quenching.

Tempering:

Tempering temperature: 430-500C, air.

Steel strip strength: Tensile strength; Elongation;Hardness

Steel strip testing: repeated bending test

Steel strip metallography: decarburization layer

Steel strip surface inspection: surface roughness