Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

SUS304 One-Stop Service For Tomato Paste Automatic Processing Production Line

Product description of tomato processing plant

The Tomato processing line can produce a variety of end products from fresh tomatoes. Popular products such as tomato paste, tomato sauce and ketchup are a tomato juice processing line that produces everything from fresh tomatoes to products made with aseptic wrap in jars.

The main processing line is: modern tomato collection system, washing system, picking system, crushing system, popping and purification system, filtration system, concentration system, disinfection system and aseptic filling system. Then we can put the tomato paste in the tub and aseptic bag.

And Tomato paste in an aseptic bag in a drum can be processed into tomato ketchup, sauce, water can be filled in bags, stand-up bags, metal cans, PP bottles, bottles, jars and more.

Gofun can not only provide tomato processing equipment for the plant, but also offer one-stop solutions from A to Z, including:

Main parameters of tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

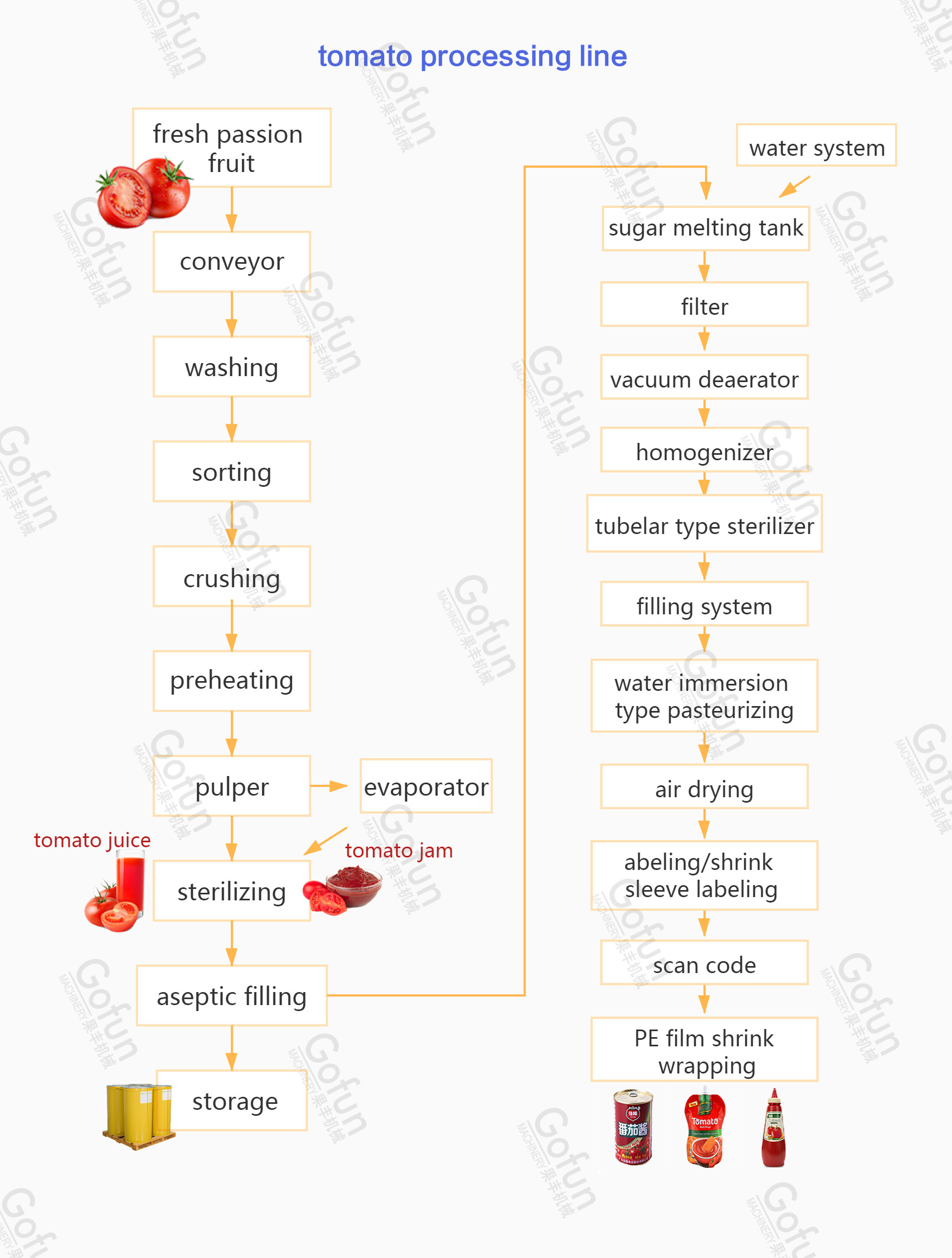

Flowchart of tomato paste/ sauce or ketchup processing

FRESH TOMATO ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ EVAPORATING ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

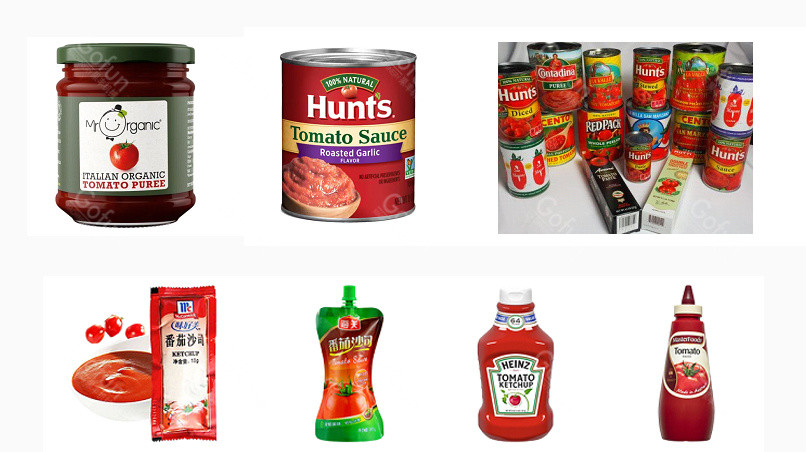

Final products & Package types for tomato project

Shanghai Gofun machinery company offers all kinds of the tomato processing line.

The raw material can be fresh tomato, tomato paste, etc. And the final product can be tomato paste, tomato ketchup, tomato sauce, tomato juice, tomato powder, whole peeled tomatoes, etc.

For final packaging it can be aseptic bag, metal can, sachet, base bag, PP container, glass bottle, pet bottle, pediment, etc.

Main features of the tomato processing line

The tomato processing line is the key product of Shanghai Gofun Machinery Company. We have served over 20 countries over the past 16 years. We continue to provide high quality machinery and service to food manufacturers around the world.

1. The capacity of new products can be adjusted from 60 tons / day to 1500 tons / day.

2. Tomato can be crushed hot and cold.

3. BRICS final tomato paste design can be according to customer's requirement, which means 28-30%, 36-38%.

4. The final tomato puree is poured into an aseptic bag in the pan. With this type of storage, the shelf life can be up to two years at normal temperature. This can reduce shipping and storage costs.

5. All foods meet food standards, the main ingredient is SUS304 or SUS316, which fully meets food hygiene and safety requirements.

6. In addition to aseptic filling of bags, we can supply bags, small bags, standing bags, glass bottles, PET / PP bottles etc.

7. The main purpose of the production line is to take the world’s first brand. (Using Spirax Sarco steam generator, Siemens PLC, etc.)

8. The whole design of the production line is small and scientific, stable performance, high strength and energy saving, low steam consumption;

9. It’s easy to work with people. All feeding and maintenance areas are constructed with feeding and maintenance platforms to ensure the safety of the operator.

10. We can also design a customized processing line for different fruits and vegetables. It can produce clear water, turmeric water, basic pulp, sodium water, pulp, fruit powder, tami, vinegar, wine and other products.

11. Wastes from the production line can be converted into fertilizer.

Our Services for tomato processing plant

1. Technical support

2. Marketing advice

3. Final packing and design ideas

4. Factory construction and design

After-Sales Service

1. Overseas technical support

2. Overseas equipment maintenance

3. English speaking machines are available to provide technical support