Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Industrial High Quality Tomato Puree Processing Line Convenient After Care Service

Product description of tomato processing plant

Tomato processing line can produce from fresh tomato to different kinds of final product. The popular products like tomato paste, tomato sauce & ketchup, tomato juice processing line, which produce from fresh tomato to the final product with aseptic bag in drum.

And the tomato paste in aseptic bag in drum can be further produced to tomato ketchup, sauces, juice and filled in sachet, stand-up pouch, metal can, PP container, bottle, gable top, etc.

Main parameters of tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

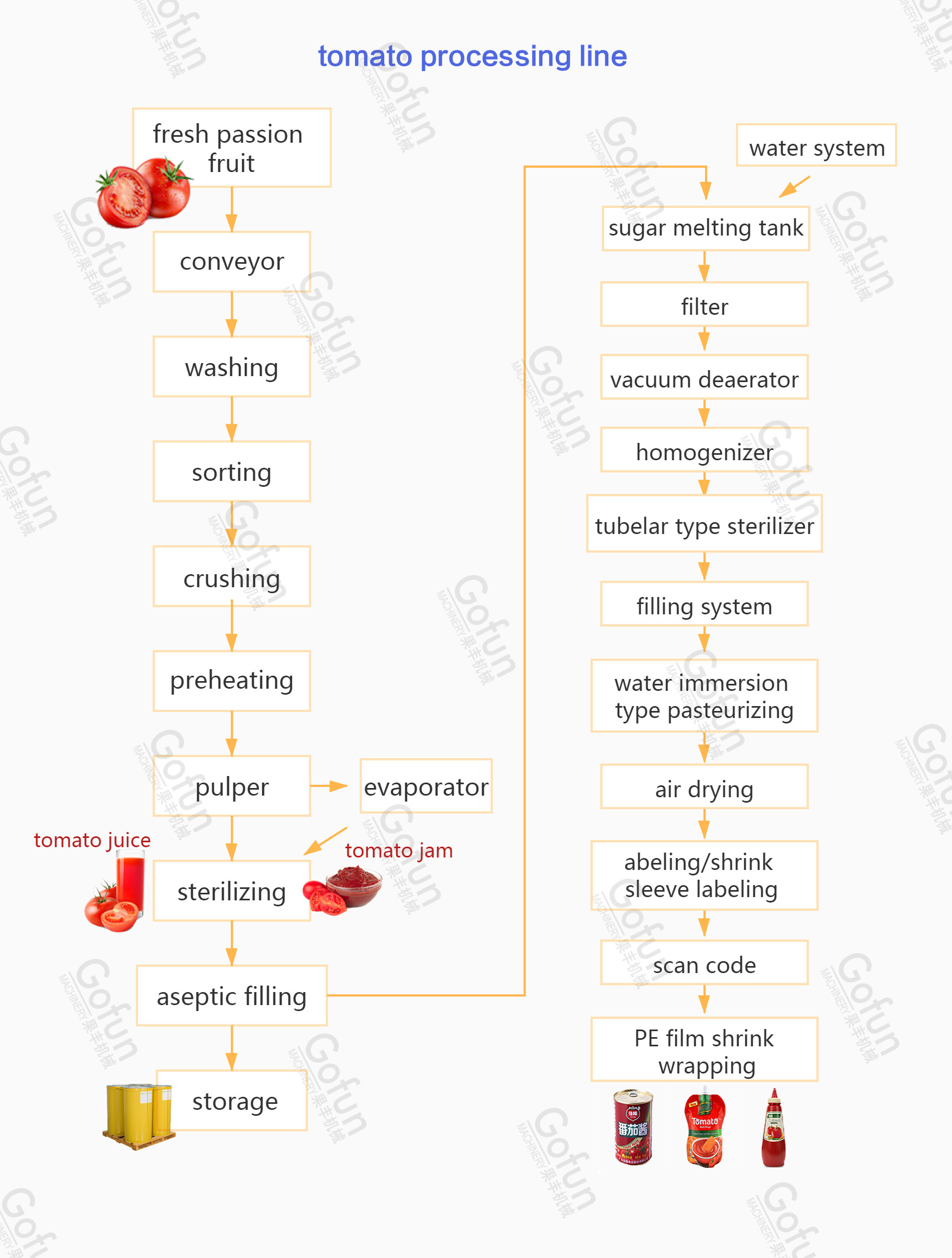

Flowchart of tomato paste/ sauce or ketchup processing

FRESH TOMATO ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ EVAPORATING ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Key process of the tomato paste processing line

Now Shanghai Gofun machinery company will introduce the information of tomato paste processing line to show it works.

1. Discharge platform

When fresh tomatoes come, they are usually large trucks. If someone unloads the goods, it will be very difficult. Therefore, we designed the unloading platform, using water guns to unload fresh fruits/tomatoes from the truck, and also using water to transport the fresh fruits/tomatoes to the processing line. The unloading platform also has a function to pre-clean fresh fruits/tomatoes before processing.

2. Elevator

This machine is used to delivery fresh fruit from outside the building to inside.

3. Washing

Before crushing, fresh fruit needs to be washed carefully. For washing, bubble washing machine and spray washing machine can be used at the same time. If the washing requirements are high, more washing stages can be added. In addition, for better cleaning effect, we can add ultrasonic cleaning and ozone cleaning.

4. Sorting

After washing, the surface of the fruit is clean, we can check the situation of all the fruit by human eye, and sort out the bad tomatoes by human.

5. Crushing for tomato processing

GFM-FC series crusher has most advanced working principle, higher accuracy of manufacture and best crushing functions. It is mainly used for crushing of many kinds of fruits or vegetables, for example: tomato, apple, pear, strawberry, celery, etc. it can crush the raw materials into small particles, which could increase the working effect of next processing section. The machine is composed of feed hopper, side cover, frame, principal axis, bearing block, motor, motor structure, outlet hopper etc.

6. Preheating

The pre-heater is used to heat the product after crusher, the temperature is adjustable, normally from 45℃ to 85℃. This processing step, would help to higher the juice rate for next step, and also can protect the color and taste of the final product.

7. Pulper and refiner

This machine is also running with speed of 1470 r/min, it causes the centrifugal force and the product will go through screen, helps to refine the product. And normally we use double stage of pulper and refiner, the screen of each stage is different, for first stage the screen would be bigger, and for second stage the screen would be smaller. The double stage pulping machine for tomato pulp yield rate can reach 90%~95%. After pulping, tomato peel and seeds will be separated from tomato pulp. The machine works with high capacity and stable performance; Easy to be operated and change sieves; Suitable for many different kinds of fruits that are including the passion fruit, tomato, peach, apricot, mango, apple and etc.;

8. Evaporating

The vacuum evaporator is used to concentrate tomato sauce under vacuum and low temperature. Here we use a forced circulation vacuum evaporator. Because it is sous vide, the taste and nutrition are protected to the greatest extent. Now, we evaporate the water in the tomato pulp, and then we will get the tomato sauce, usually the Brix is 28-30% and 36-38%.

9. Sterilizing

For tomato paste we use tube in tube type sterilizer for sterilizing. The sterilizing temperature and holding time is adjustable. With this machine we will heat the tomato paste to a very high temperature around 115℃ holding for 30s and then cooling to ambient temperature immediately. Like this way also can protect the test and nutrients of tomato paste as much as possible. The whole system adopts programmable control. The operating system adopts the image man-machine interface, which is convenient for intuitively grasping the operating status of each component of the device.

10. Aseptic Filling

The aseptic filling machine works together with the tube in tube type sterilizer. It’s a closed cycle. Before production, the cycle will be fully sterilized to make sure the aseptic environment. And the filling cavity is also protected by steam to make sure the filling environment is also aseptic. Safety - providing several security methods. Using mirror welding tech to ensure tidy and smooth welding line. Separate control panel. CIP and auto SIP available together with sterilizer. Easy to adjust to match the different volumes and sizes of aseptic bags

11. Storage or go blending

The finished product can be stored or used as the raw material to make the tomato sauce or ketchup.