Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

High-Quality Tomato Processing Plant Aseptic Bag In Drum Package Field Installation

Product description of tomato processing plant

Utilizing tomato processing lines, fresh tomatoes can undergo processing to create a range of finished products, including tomato paste, tomato sauce and ketchup, and tomato juice. To guarantee the quality and freshness of the final products, they are packaged in aseptic bagged drums, ensuring their integrity and freshness from start to finish during the production process.

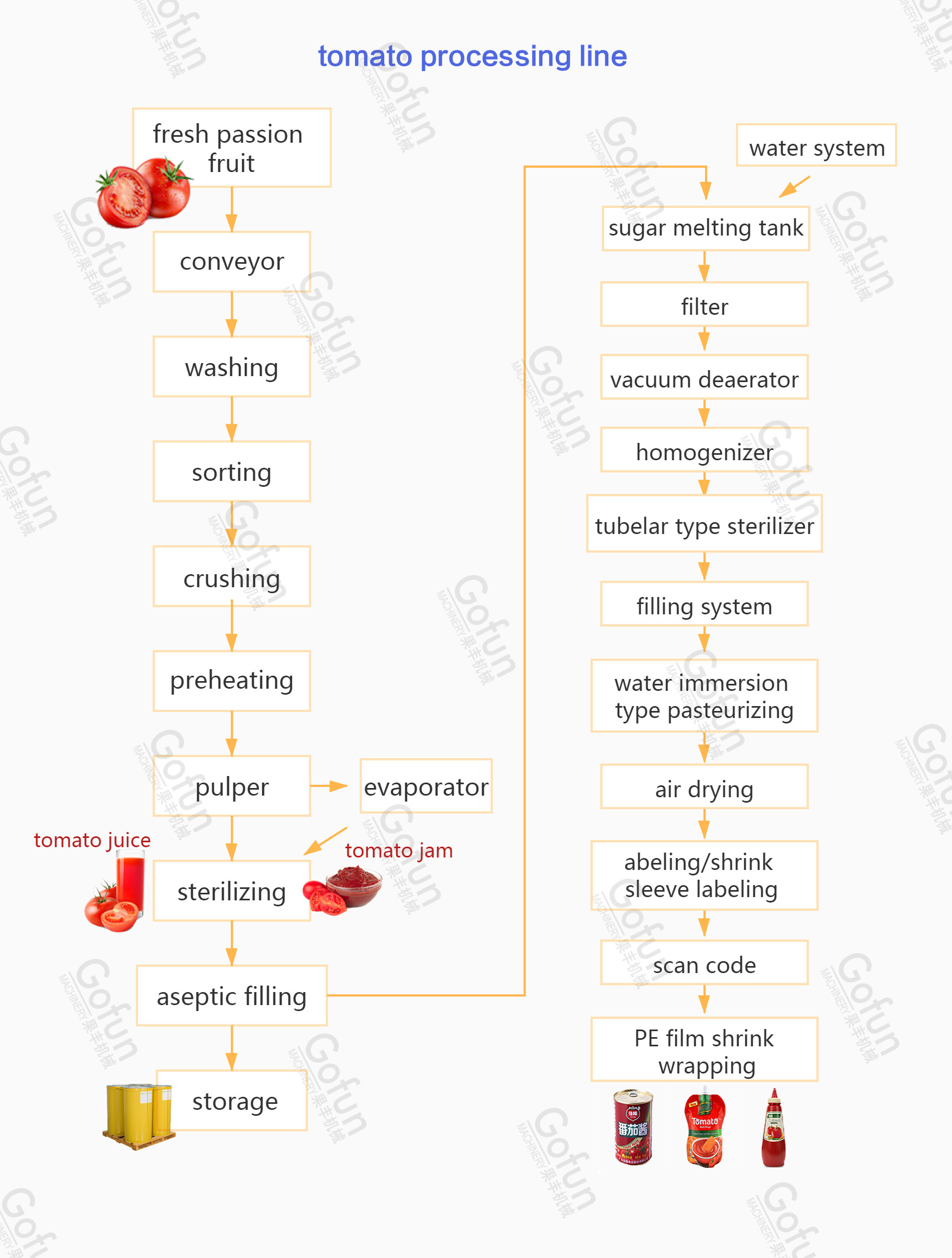

The tomato processing line consists of several key components, including a raw tomato receiving system, washing system, sorting system, crushing system, pulping and refining system, filtration system, concentration system, pasteurization system, and aseptic filling system.

Our service of the tomato processing plant

Gofun not only provides tomato processing equipment for your factory, but also provides a one-stop solution from A to Z, including:

Main parameters of the tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

Flowchart of tomato paste/ sauce or ketchup processing

FRESH TOMATO ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ EVAPORATING ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

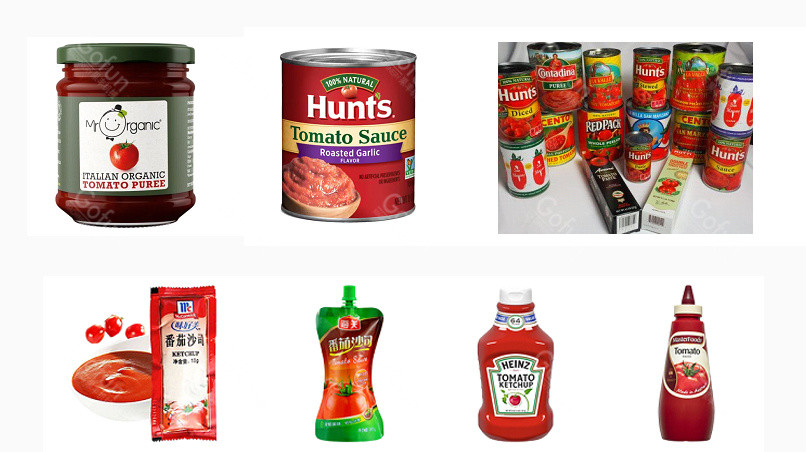

Final products & Package types for the tomato project

Shanghai Gofun machinery company offers all kinds of the tomato processing line.

The raw material can be fresh tomato, tomato paste, etc. And the final product can be tomato paste, tomato ketchup, tomato sauce, tomato juice, tomato powder, whole peeled tomato, etc.

For the final package, it can be an aseptic bag, metal can, sachet, stand-up pouch, PP container, glass bottle, PET bottle, gable top, etc.

The key process of the tomato paste processing line

Now Shanghai Gofun machinery company will introduce the information of tomato paste processing line to show it works.

1. Ejection platform

To enhance the efficiency of unloading fresh tomatoes from large trucks, we have introduced an innovative discharge platform. This platform incorporates water jets to efficiently remove the tomatoes from the trucks, eliminating the need for labor-intensive manual handling. Additionally, the discharge platform serves as a preliminary washing step for the fresh tomatoes before they enter the processing line. Water is used to facilitate the smooth transfer of the fresh tomatoes into the processing line, ensuring a seamless and uninterrupted operation.

2. Elevator

A machine that delivers fresh fruit from outdoors to indoors.

3. Washing

Prior to the crushing stage, thorough cleansing of the fresh tomatoes is crucial. To achieve exceptional cleaning results, a combination of a bubble washer and a spray washer can be employed. If more rigorous cleaning standards are necessary, additional cleaning stages can be incorporated. Moreover, the cleaning process can be further enhanced by integrating ultrasonic cleaning and ozone cleaning techniques, which augment the effectiveness of the cleansing process.

4. Sorting

After washing, the surface of the fruit is clean, we can check the situation of all the fruit by human eye, and sort out the bad tomatoes by human.

5. Crushing for tomato processing

The GFM-FC series crusher operates on a cutting-edge working principle, offering superior production precision and the highest crushing capacity available. Its main function is to pulverize an extensive array of fruits and vegetables, effectively transforming them into finely ground particles and optimizing the efficiency of subsequent processing steps. This machine consists of multiple elements, such as a feeding hopper, side panel, framework, primary shaft, bearing block, motor, motor structure, and discharge hopper. These elements collaborate seamlessly to facilitate the crushing procedure and guarantee uninterrupted operation.

6. Preheating

A pre-heater is used to heat the product after grinding, and the temperature is usually adjustable from 45°C to 85°C. This processing step helps increase the juice percentage for the next step and can also preserve the color and taste of the final product.

7. Pulper and refiner

Operating at a rotational speed of 1470 revolutions per minute (r/min), this machine harnesses centrifugal force to propel the product through the sieve, facilitating the purification process. It comprises two distinct stages: the Pulper and the Refiner, each equipped with a different sieve size. The initial stage incorporates a larger sieve, while the subsequent stage utilizes a smaller one. By employing this dual-stage pulping machine, an impressive tomato pulp yield ranging from 90% to 95% can be attained. The pulping process effectively separates the tomato skin and seeds from the pulp. Renowned for its notable production capacity, consistent performance, user-friendly operation, and convenient sieve replacement, this machine is suitable for processing various fruits, such as passion fruit, tomatoes, peaches, apricots, mangoes, apples, and more.

8. Evaporating

Vacuum evaporator is used to concentrate tomato paste under vacuum and low temperature. A forced circulation vacuum evaporator is used here. Since it is finished at a vacuum low temperature, it does not miss the taste and nutrients as much as possible. Then the water is evaporated from the tomato pulp to make a tomato paste. Brix is typically 28-30%, 36-38%.

9. Sterilizing

In order to guarantee the safety and preservation of tomato paste, a tube-in-tube type sterilizer is utilized. This sterilizer offers adjustable sterilization temperature and holding time. The machine efficiently heats the tomato paste to a high temperature, typically around 115°C, and maintains it at this temperature for approximately 30 seconds. Subsequently, the tomato paste is rapidly cooled to the surrounding temperature. The entire system is designed to provide comprehensive protection, facilitated by its programmable control. The operating system incorporates an intuitive image-based man-machine interface, enabling operators to effortlessly monitor the status of each component of the device.

10. Aseptic Filling

The aseptic filling machine operates in conjunction with a tube-in-tube type sterilizer, forming a closed cycle. Prior to production, the cycle undergoes complete sterilization to establish an aseptic environment. Special measures are taken to protect the filling cavity from steam and maintain a sterile filling environment. Several security methods are implemented, including the utilization of mirror welding technology to achieve clean and seamless welding lines. The machine features an independent control panel for efficient operation. It also offers CIP (Clean-in-Place) and Auto SIP (Sterilize-in-Place) functions within the sterilizer. Additionally, it can be easily adjusted to accommodate various capacities and sizes of sterilization bags.

11. Storage or go blending

The finished product can be stored or used as the raw material to make the tomato sauce or ketchup.