Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

380V Fully Automatic Factory Tomato Paste Processing Water Saving

Product description of tomato processing plant

The tomato production line is equipped with the ability to manufacture various finished goods using fresh tomatoes. Popular products include ketchup, tomato sauce, and tomato paste. Additionally, there is a separate production line for tomato juice that employs aseptic tank bags throughout the process, starting from the initial stage of using fresh tomatoes until the final product is obtained.

The production line configuration typically incorporates a range of components to ensure efficient manufacturing. These components include a state-of-the-art tomato picking system, cleaning systems, sorting systems, grinding systems, filtration and purification systems, concentrating systems, sterilization systems, and aseptic filling systems. This comprehensive setup guarantees the production of top-notch ketchup, which is carefully packaged in clean bags or buckets to maintain its quality.

And can produce aseptic ketchup bags for ketchup, sauce, juice and packaging bags, stand-up bags, metal cans, PP containers, bottles, sprockets, etc.

Gofun can not only provide tomato processing equipment to factories, but also provide complete solutions from A to Z, including:

Main parameters of tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

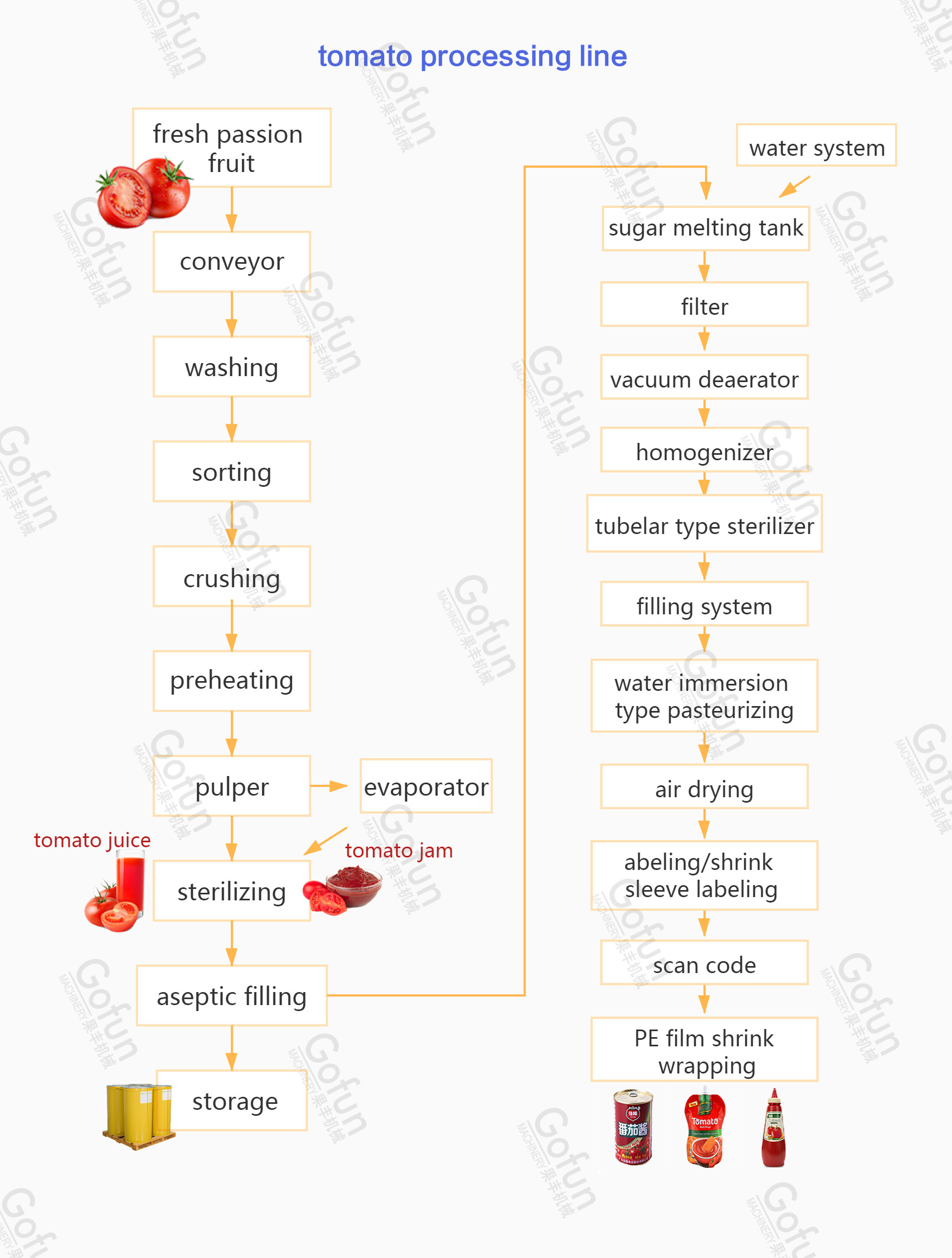

Flowchart of tomato paste/ sauce or ketchup processing

FRESH TOMATO ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ EVAPORATING ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

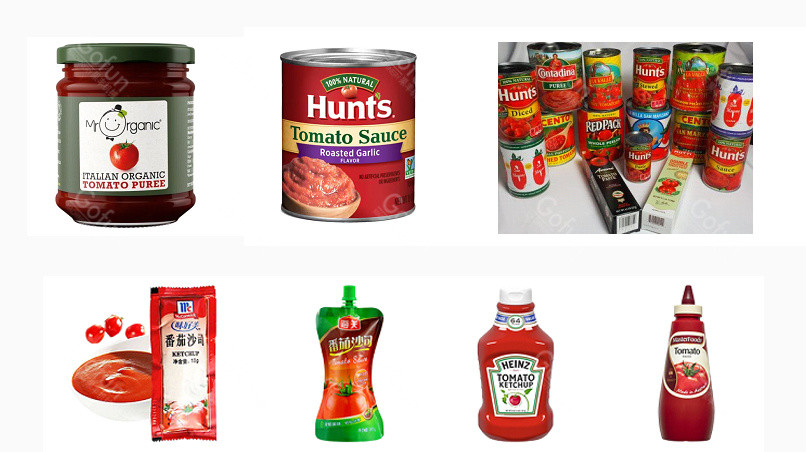

Final products & Package types for tomato project

Shanghai Gofun machinery company offers all kinds of the tomato processing line.

Raw products are raw tomatoes, tomato paste, etc., and finished products are ketchup, ketchup, ketchup, tomato juice, tomato powder, peeled whole tomatoes, etc.

Final packaging includes sterile bags, canisters, envelopes, block bottoms, PP containers, glass bottles, PET gable bottles, etc.

Main features of the tomato processing line

The flagship product of Shanghai Gofun Machinery Company is the tomato processing lines, in which we specialize. With a rich experience of 16 years, we have successfully catered to customers from over 20 countries. Our primary focus is on providing exceptional machines and services to food manufacturers worldwide, enabling them to access top-quality equipment for their tomato processing requirements. We remain committed to delivering consistent excellence in our offerings, ensuring the utmost satisfaction of our customers.

1. The capacity for processing fresh fruit can be tailored to meet specific requirements, ranging from 60 tons per day to 1500 tons per day.

2. The tomato can be hot crushed or cold crushed.

3. The Brix of final tomato paste can be designed as the customer’s requirement, normally it would be 28-30% or 36-38%.

4. The tomato paste is ultimately packaged in aseptic bags within drums. This packaging method extends the shelf life of the tomato paste to up to two years at regular room temperature. By utilizing this type of packaging, transportation and storage costs are significantly reduced, resulting in substantial cost savings for our customers.

5. All the materials are food standard, the main material is SUS304 or SUS316, which fully meets the requirements of food hygiene and safety.

6. Besides aseptic bag filling, we can also provide metal can, small sachet, stand-up pouch, glass jar, PET/PP container, etc.

7. Key points of the production line adopt the international first brand. (Steam valve adopts Spirax Sarco, Siemens PLC etc.)

8. The design of the entire production line is compact and scientifically engineered, ensuring stable operation, high efficiency, and energy-saving performance. The system is optimized to minimize steam consumption, resulting in cost-effective operations and reduced energy requirements.

9. The operation of our tomato processing lines is designed to be simple and user-friendly. We have implemented humanized features throughout the production line. Specifically, all feeding and maintenance areas are equipped with dedicated platforms to ensure the safety and security of the operators. These platforms provide convenient access for feeding raw materials and carrying out maintenance tasks, prioritizing the well-being of the operators and enhancing overall operational efficiency.

10. We possess the expertise to design tailor-made processing lines that cater to diverse types of fruits and vegetables. Our versatile production lines are capable of manufacturing an extensive array of products, including clear juice, turbid juice, original pulp, concentrated juice, concentrated pulp, fruit powder, jam, vinegar, wine, and various other products. This flexibility in our production capabilities allows us to meet the specific requirements and preferences of our clients, offering them a comprehensive range of options for their fruit and vegetable processing needs.

11. The byproducts generated from our production line can be effectively repurposed into fertilizer. Instead of discarding the waste, we have implemented a system that allows us to convert it into valuable fertilizer. This sustainable approach helps us minimize waste and contribute to environmental conservation by utilizing the byproducts in an eco-friendly manner. By transforming the waste into fertilizer, we promote a circular economy and reduce the overall environmental impact of our operations.