Xinghe Roll Forming Machinery Co.,Ltd |

|

| Style | used metal roof tile making machine |

| Machine dimension | 6800*1550*1350mm |

| Total weight | 5200kgs |

| Forming steps | 9rows / 11 rows |

| Forming speed | 10-12m/min |

| Hydraulic station power | 4.0kw |

| Diameter of shaft | 75mm |

| Hydraulic pressure | 18-20Mpa |

| Electric condition | 380V/3Phase/ 50HZ |

| Suitable to process | color steel coil ppgi/ppgl gi/gl |

| Decoiler max capacity | 4-6tons |

| Control system | PLC control |

| Raw material thickness | 0.2-0.8mm |

| Effective width | 840/900mm |

| Material width | 1000mm |

| Main application | tile roof |

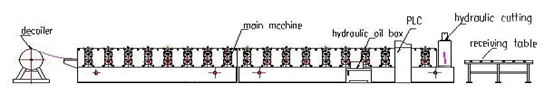

Parts of double layer roof making machine :

| Decoiler | 1set |

| Feeding & guiding device | 1set |

| Main roll forming machine | 1set |

| Hydraulic pressing system | 1set |

| Hydraulic cutting system | 1set |

| Controlling system | 1set |

| Run out table | 1set |

Double layer roof making machine Process flow:

Main Products of our company :

1. Our roof tile Making Machine (except wearing parts) come with 12 months warranty. Within the 12 months period, for any parts damaged due to quality problems, we offer the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in

the clients' factories.

A. Roll forming machinery: which could produce matalic roofing

tile, trapezoidal or sinusoidal roofing sheet, floor deck, C and Z

purlin, expressway guardrail, channel and stud, roller shutter and

sandwich panel, etc. Customized profiles and requirements are

acceptable, and assistant equipments such hydraulic decoiler, auto

stacker, etc.

B. Steel structure Building: Complete service including design,

fabrication, delivery and installation supervision for PEB

industry, such as warehouse, workshop, shopping mall, highrise

building, etc.

C. Related products: Metal material for PEB building and other

related equipments, like H-beam process machinery, slitting/CTL

machine, etc.

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 3 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled

technicians available across the world.We need your machines

running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to

Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai

Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't

repair,we can send the new parts replace the broken parts

freell,but you need pay the express cost yourself.if after warranty

period,we can through negotiationfor to solve the problems,and we

supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich

experience in transport.

6. You are trade company or factory?

We are factory with professional production team and service

consciousness just for exporting various types of cold roll forming

machines.

7. Why your price is higher than others?

As we persist on that each factory should put quality at the first

place. We spend time and money on developing How to make machines

much more automatic, accurate and high quality. We can make sure

thatour machine could use more than 15 years without any problem.

We can provide 1 years free qualityassurance.

8. How long the machine could be made?

Jenerally speaking, the machine could be made without 20working

days .But if you need machines in a hurry,we can make it for you

less than 15days .