Xinghe Roll Forming Machinery Co.,Ltd |

|

1.Machine technical Parameters

| 1) Main Motor Power: 4.0KW |

| 2)Hydraulic Station Power: 4KW |

| 3) Hydraulic Oil Pump: CB-E310 |

| 4)Sprocket: P-25.4 |

| 5)Roller Station: 11 |

| 6)Yield Strength: 32MPa |

| 7)Diameter of Principal Axis: 75mm |

| 8)Material of Roller: 45#steel hard chrome plating |

| 9)Processing Speed: 0-15m/min |

| 10)Thickness: 0.3-0.8mm |

| 11)Installation Dimension (L*W*H): 6.0m*1.5m*1.2m |

| 12)Total Weight: 2.0T |

| 13)Coil Width: 1000/1200mm according to customer's requirments |

| 14)Cover Width: 860/1075mm according to customer's requirments |

| 15)Equipment Parts: forming machine, hydraulic cutter, hydraulic station, electric controlling system and counter. |

| Decoiler | 1set |

| Feeding & guiding device | 1set |

| Main roll forming machine | 1set |

| Hydraulic cutting system | 1set |

| Controlling system | 1set |

| Run out table | 1set |

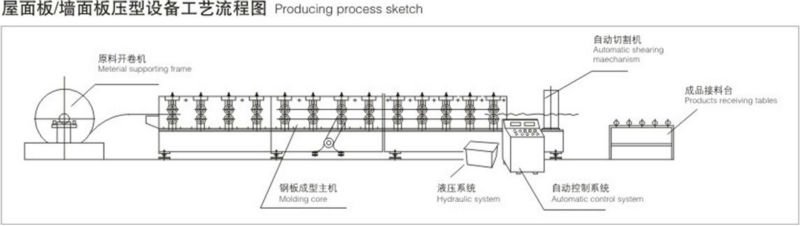

2. Machine process flow

3. Machine and detailed images pictures

This kind of machine has the best quality and the best price. It has accurate measurement and easy operating. We can design and manufacture the special type machine according to the customers’ requirement and we could provide technical guiding, production, installation, debugging and maintenance service to all customers.

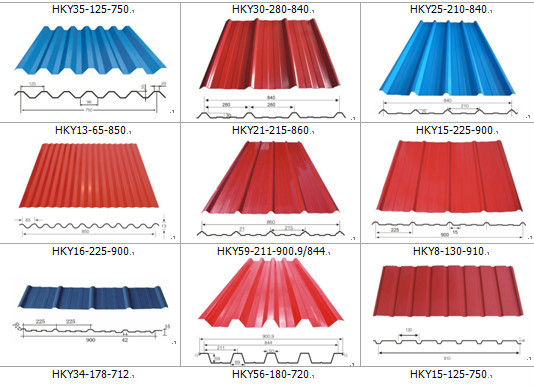

6. other roll forming machines

1)Wall and roofing sheet roll forming machine / Metal tile forming machine

2)C/Z purlin Auto size quick change forming machine

3)Floor decking forming machine

4)Highway guardrail roll forming machine

5)Sandwich rollforming machine

6)Stud and Track forming machine

7) Light keel roll forming machine

8)Roller Shutter Door Roll Forming Machine

- Before use the glazed tile roll forming machine, you need to check the connections around the firm, installation bolts, nuts are tightened, the left and right chassis should be sufficient lubrication oil, the power to start the machine to test the first empty car carefully observed, with or without vibration, noise, oil window Whether the oil, the parts movement is coordinated, everything is normal before you can install the mold, install the mold, you must cut off the power, manually moving the motor belt or gear, the table indexing, and the slider to the highest point, It is best to use an object support between the table and the bottom of the carriage to prevent the carriage from falling, causing an accident.