Jinan Zhuoheng Extrusion Machinery Co., Ltd. |

|

Verified Suppliers

|

|

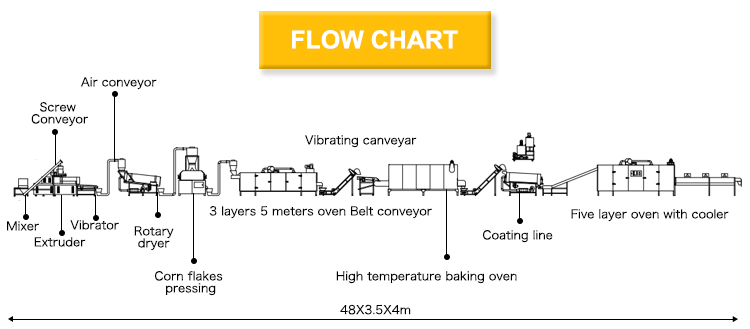

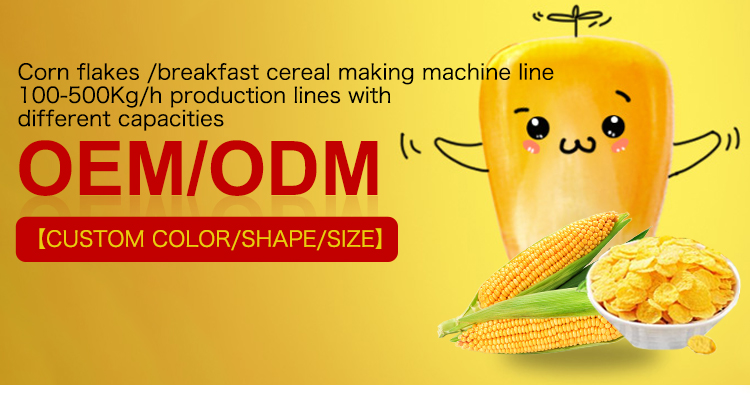

Model | Installed Power | Consumption Power | Output | Dimension |

ZH65 | 310kw | 186kw | 120-150kg/h | 39000x1200x2200mm |

ZH70 | 348kw | 208kw | 200-250kg/h | 41000x1500x2200mm |

ZH85 | 425kw | 255kw | 400-500kg/h | 43000x3500x4300mm |