Dongguang Xinglong Packaging Machinery Co., Ltd. |

|

WJ80-2000 3ply Corrugated Cardboard Production Line

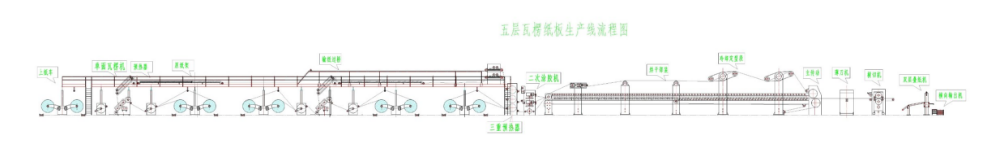

Corrugated cardboard production line is the professional advanced equipment for produce 3ply, 5ply, 7ply corrugated cardboard. The production line consists of mill rolls tand, liner(medium paper) pre-heater, single facer machine, conveyor bridge, gluing machine, double baker, slitter scorer machine, NC cut-off, conveyor and stacker, heating system. Air compression system, glue making system etc.

We produce different grade machines according to customers’ demand of speed, function

Main specification

1. width:1400mm, 1600mm, 1800, 2000, 2200, 2500mm

2. Design speed: 200m/min, 150m/min, 120m/min, 100m/min, 80m/min

3. Heating method: steam

Corrugated cardboard type and instruction

Single wall corrugated cardboard (also called 3layer, 3ply board)

1. Our most popular corrugated material used in boxes

2. Available in a wide range of compression strength 125Iib to 275ib

Flute type

| Flute type | A | B | C | D | E | F | G | others |

Flute shape | UV | UV | UV | UV | UV | UV | UV | |

Teeth number /300mm | 30 ±2 | 50 ±2 | 39 ±2 | 20 ±1 | 90 ±10 | 124 ±10 | 185 ±12 | customized |

Height of flute | 4.6~ 4.9 | 2.6~ 2.9 | 3.6~ 3.9 | 7.2~ 7.5 | 1.1~ 1.5 | 0.7~ 0.8 | 0.5~ 0.65 | customized |

| Shrinkage | 1.51~ 1.59 | 1.36~ 1.42 | 1.44~ 1.51 | 1.45~ 1.49 | 1.29~ 1.39 | 1.22~ 1.26 | 1.20~ 1.25 | customized |

Parameter for WJ80-2000 3ply corrugated cardboard line

| Model | WJ80-2000 |

| Max Effective width | 2000mm |

| Design speed | 80m/min |

| Working speed | 0-60m/min |

| Steam pressure and consumption | Pressure: 1-1.3Mpa consumption: 1800kg/h |

| Air pressure and consumption | Pressure: 0.8-1.0Mpa consumption: 1.3m³/min |

| Cutting length and precision | 500—9999mm ±1mm |

| Total power | About 180kw |

| Total length | About 60m (depend on base drawing) |

| Dimension | About 60m×4.5m× 4.5 m (L×W×H) |

| Equipment flow: according the customers’ workshop to installation the machine. | |

Configuration list for WJ80 3ply corrugated cardboard line

| SL | Goods and description | Qty |

| 1 | Electric shaftless mill roll stand 1. Expansion clamp, Pneumatic control brake 2. Lift-down, clamp, move controlled by motorized | 3sets |

| 2 | Trolley and rail 1. Rail length:6000mm, trolley welded by 10mm middle plate | 6 sets |

| 3 | RG-1-600 Pre-heater 1. Diameter:φ600mm 2. Electric wrapping in 360 degree | 2 sets |

| 4 | SF300-1600 Single facer 1. Corrugated roller diameter: φ300mm, 48CrMo alloy steel 2. Independent gear box with gimbal drive machine 3. Variable frequency motor drive 4. Glue width adjusted by motor control | 1 set |

| 5 | RG-2-600 Pre-heater 1. Diameter:φ600mm 2. Electric wrapping in 360 degree | 1 set |

| 6 | TJ215-1600 Single glue machine 1. Glue roller diameter: ¢215 mm 2.Variable frequency motor drive 3. Stainless steel glue tank | 1 set |

| 7 | TQ1600 Conveyor bridge 1. Electrical deviation-rectifying device, adsorption tension | 1 set |

| 8 | SMJ Double facer 1. Hot plate 600mm×12 pcs 2. cooling section length 4m 3. Dense pressure roller controlled by motor 4. High quality gear drive machine, oil-immersed lubrication, variable frequency motor drive 5. Good quality cotton woven belt | 1 set |

| 9 | BFY-DP-1600 Thin blade slitter creaser (online type) 1. Rectify deviation by motorized 2. Knife moved by motorized, pneumatic locking 3. 4blades 6 creasers, blade made of tungsten alloy steel | 1 set |

| 10 | Helix NC cut-off 1. AC servo motor control helix knife 2. Germany brand “KEB” servo driver | 1 set |

| 11 | Stacker 1. Electric adjust cardboard size 2. Pneumatic control horizontal output 3. Frequency motor drive machine 4. 2 section belt convey board tidy | 1 set |

| 12 | Glue make system 1. Include carrier glue barrel, main body glue barrel, store barrel and glue pump 2. glue pipe prepared by customers | 1 set |

| 13 | Steam system 1. Adopts national standard valves. Include rotary joint, trap, and pressure gauge 2.Boiler and main pipe prepared by customers | 1 set |

| 14 | Electric control system 1. Electric box surface with electrostatic spraying, wearable and beautiful2. Famous brand contactors, delay | 1 set |

| 15 | Compressed air system Air compressor 1pcs Air storage tank 1pcs | 1 set |

Option

| SL | Goods and description | Qty |

| 1 | Hydraulic mill roll stand 1. Expansion clamp, Pneumatic control brake 2. Lift-down, clamp, move controlled by hydraulic | 3sets |

Trolley and rail 1. Rail length:6000mm, trolley welded by 10mm middle plate | 6sets | |

| 8 | Thin blade slitter creaser (up-down type) 1. Rectify deviation by motorized 2. Knife moved by motorized, pneumatic locking 3. 5 blades 8 creasers, blade made of tungsten alloy steel 4. Electric control knife and creaser part go up and own , can suit for different feed height | 1set |