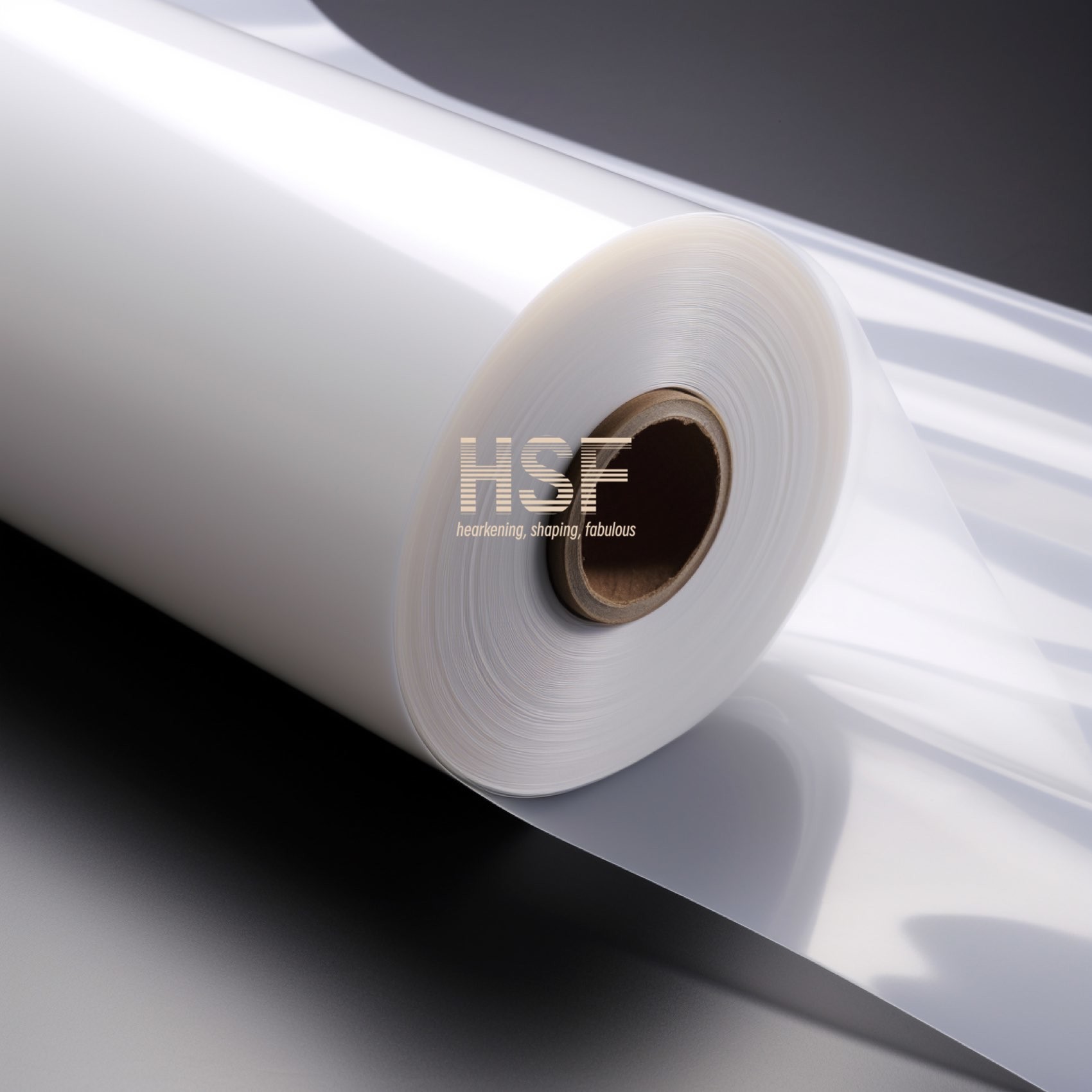

Shanghai HSF Materials Technology Co., Ltd. |

|

Verified Suppliers

|

|

Monoaxially oriented polyethylene film (MOPE) has several advantages compared to ordinary types of polyethylene films.

Some of the advantages of MOPE are:

1. Higher Strength:

MOPE films have higher tensile strength and puncture resistance compared to regular polyethylene films.

This makes them more suitable for applications where higher strength is required.

2. Better Clarity:

MOPE films have superior optical properties and offer exceptional clarity and gloss, which improves the visibility of the packaged product.

3. Improved Barrier Properties:

MOPE films have better barrier properties, which make them an excellent choice for applications that require a higher level of protection

against moisture, gases, and other contaminants.

4. Stable Dimensions:

MOPE films are designed to have stable dimensions, even when subjected to thermal treatments.

This property allows MOPE films to maintain their shape and size during manufacturing processes, ensuring consistent performance.

5. Customizable Performance:

MOPE films are available in different grades and can be customized to meet specific performance requirements such as thickness,

stiffness, and tensile strength.

6. Reduced Material Consumption:

Compared to regular polyethylene films, MOPE films can be produced with lower thickness without sacrificing their mechanical properties,

resulting in less material consumption and reduced costs.

MOPE films offer several advantages over regular polyethylene films, including improved strength, clarity, barrier properties,

stable dimensions, customizable performance, and reduced material consumption. These properties make MOPE films an excellent choice

for a wide range of applications, including food and beverage packaging, pharmaceutical packaging, and industrial packaging.

Here are some common products made of monoaxially oriented polyethylene film (MOPE):

1. Flexible Packaging:

MOPE film is commonly used in flexible packaging applications such as pouches, bags, and sachets for food, pet food, and non-food products.

2. Industrial Packaging:

MOPE films are used in heavy-duty industrial packaging applications, such as wrapping pallets and protecting products during transportation.

3. Labels:

MOPE films are used for creating labels and stickers for packaging purposes.

4. Overwraps:

MOPE films are used for overwrapping products such as boxes, soap bars, and other products for protection and branding purposes.

5. Laminations:

MOPE films are used in laminated structures to provide barrier properties, such as in food packaging, industrial packaging,

and medical packaging.

6. Shrink Wraps:

MOPE films are used in shrink wrapping applications for products such as bottles, cans, and boxes.

7. Medical Packaging:

MOPE films are commonly used in medical packaging applications, such as for packaging syringes, IV bags, and medical devices.

There are several ways to increase the properties or other desirable functions of MOPE (monoaxially oriented polyethylene) film.

Here are some examples:

1. Blending with Polymers:

MOPE can be blended with other polymers to improve or modify its properties. For example, blending MOPE with ethylene vinyl acetate

(EVA) can improve transparency and flexibility, while blending it with polypropylene can improve heat resistance and stiffness.

2. Coating or Lamination:

MOPE can be coated or laminated with other materials to enhance its barrier properties or add functionalities. For example, coatings with

aluminum or metallized films can improve moisture and gas barrier properties, while coatings with water-based acrylics can increase printability

and adhesion.

3. Crosslinking:

Crosslinking MOPE using radiation or chemical crosslinking agents can improve its mechanical properties, thermal stability, and chemical

resistance.

4. Orientation:

MOPE can be orientated in multiple directions to improve its mechanical properties, such as tensile strength and puncture resistance.

Biaxial orientation can also improve optical properties such as clarity and gloss.

5. Additives:

MOPE can be modified by adding functional or performance-enhancing additives. For example, adding slip agents to reduce friction

and improve processing, or adding anti-block agents to reduce blocking during storage.

6. Molecular Weight Control:

Bringing a change in the molecular weight of MOPE can improve its mechanical and barrier properties.

A higher molecular weight enhances mechanical strength, while a lower molecular weight can improve flexibility and processability.

These approaches can help manufacturers modify the properties or add desirable functions to MOPE film for various packaging

and industrial applications.

30 micron translucent white monoaxially oriented polyethylene (PE) film can be used in various application scenarios where a thin, flexible, and translucent white film is desired. Here are some potential uses for 30 micron translucent white monoaxially oriented PE film:

Packaging and wrapping: The translucent white film can be used in packaging and wrapping applications. It can be employed as a protective layer or wrapping material for various products, offering a combination of visibility and protection while maintaining a translucent white appearance.

Lamination: The translucent white film can be used for lamination purposes. It can be employed as a top layer in laminated materials, providing a protective and translucent white layer to preserve and enhance the appearance of documents, photographs, or other printed materials.

Labels and stickers: The translucent white film can find applications in labels and stickers. It can be used as a component in adhesive labels or stickers, offering a slightly opaque and visually appealing background for product information, branding, or decorative purposes.

Crafts and DIY projects: The translucent white film can be used in crafts and DIY projects. It can be employed as a decorative material for scrapbooking, card making, or other creative endeavors, providing a translucent white element to enhance the design.

Window decals and graphics: The translucent white film can be used for window decals and graphics. It can be employed as a print-receptive surface for window displays or decorations, allowing light transmission while providing a translucent white background for the graphics.

Privacy films: The translucent white film can find applications in privacy films. It can be used as a component in window films or glass coatings, offering a level of opacity while allowing light to pass through, enhancing privacy in residential, commercial, or automotive settings.

Light diffusers: The translucent white film can be used as a light diffuser. It can be employed as a material for lampshades, light fixtures, or signage, diffusing and softening the light for a more visually pleasing effect.

Backing material: The translucent white film can be used as a backing material in various applications. It can serve as a backing for adhesive products, such as tapes or labels, providing a consistent and slightly opaque surface for adherence.

Book covers: The translucent white film can be used as a book cover material. It can be employed to protect books, notebooks, or other printed materials while allowing some visibility of the content through the translucent white layer.

Industrial applications: The translucent white film can find applications in different industrial settings. It can be used as a component in manufacturing processes, such as protective covers, release liners, or as a barrier layer in certain applications where a thin, flexible, and translucent white material is required.

These are some potential application scenarios for 30 micron translucent white monoaxially oriented PE film. Its thinness, flexibility, and translucent white color make it suitable for a range of uses in industries such as packaging, lamination, labels, crafts, window decals, and more.