Shanghai HSF Materials Technology Co., Ltd. |

|

Verified Suppliers

|

|

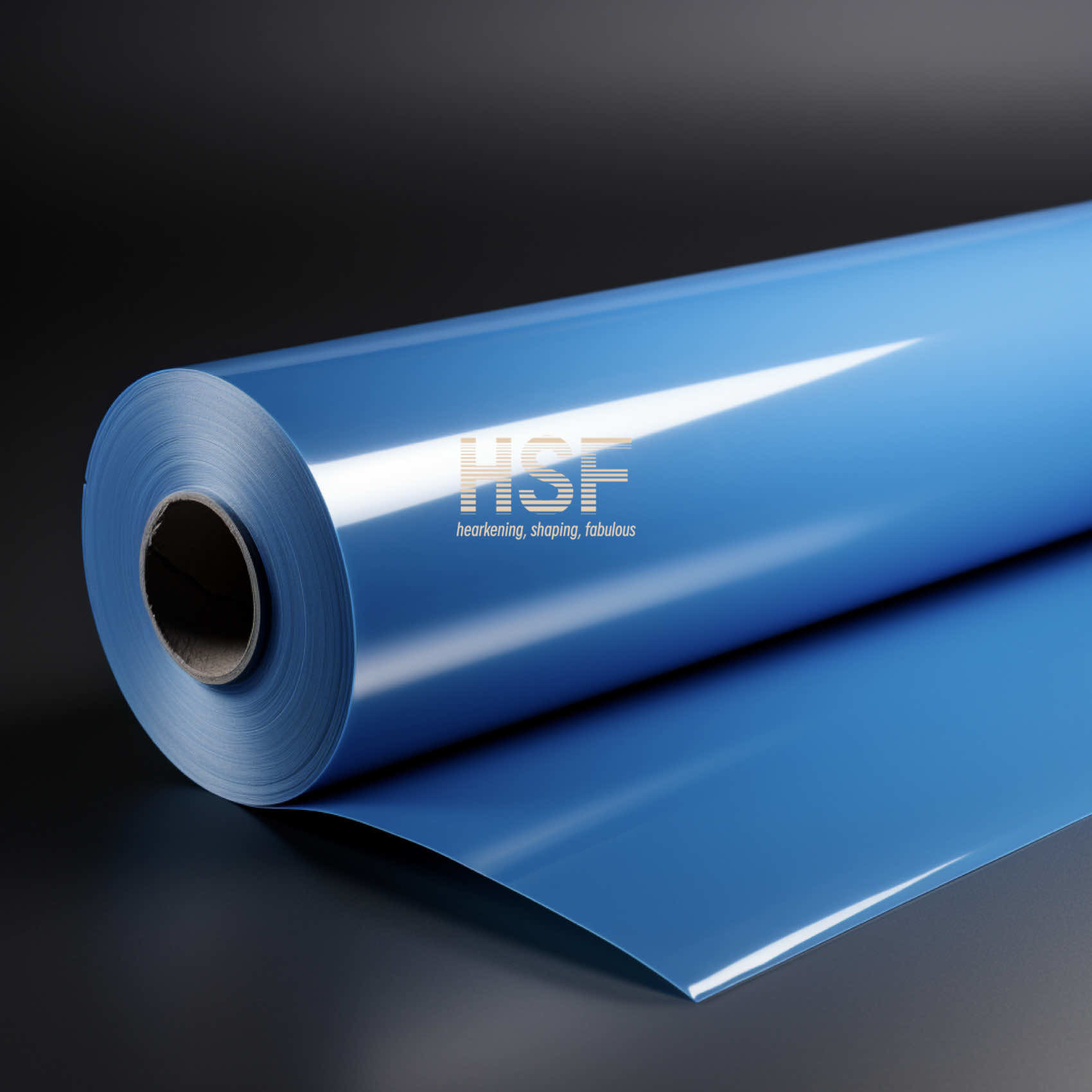

40 μm blue cast polypropylene film for food, medical can industrial packaging

Translucent blue or opaque blue cast polypropylene (CPP) film with a thickness of 40 microns is a versatile packaging material suitable for a range of applications. CPP film is a popular choice for food packaging with its excellent puncture resistance and superior sealing properties.

The film finds its use in packaging cosmetic and personal care products, stationery and office supplies, and industrial items, such as adhesives and tapes. CPP film also makes good labels for several products due to its printability and translucency. CPP film is known for its high durability and flexibility and provides excellent protection to the products during transportation, hence ideal for agriculture packaging.

One of the significant features of cast polypropylene film is its excellent transparency, and good moisture barriers, which makes it a suitable packaging material where product visibility is essential. CPP film also possesses superior strength, puncture resistance and thermal stability, which allows it to withstand rough handling during transportation. CPP film is a reliable option for packaging applications that demand consistent performance. It is ideal for using visual cues as branding elements on packaging with excellent clarity and superior dimensional stability.

The production of CPP film involves the polymerization of propylene monomers, melting and extrusion of the polypropylene resin pellets, orientation of the extruded film, cooling of the film, and finishing by corona discharge or other surface treatments to improve printing quality and adhesion.

Comparing CPP film with Biaxially Oriented Polypropylene (BOPP) film, CPP film provides

1. Enhanced sealing properties with higher seal strength,

2. Better clarity, and gloss, better hot tack properties,

3. Increased heat resistance, and higher puncture resistance.

CPP film is preferred for packaging applications in food, industrial and agricultural sectors.

| Test Item | Unit | Range | Test Standard | |

| Thickness | Avg. | μm | 40 | GN/T 6672 |

| Max. | ≤44 | |||

| Min. | ≥36 | |||

| Width | Avg. | mm | 1090 ±3 | GN/T 6673 |

| Tensile strength | MD | MPa | ≥20 | GN/T 1040.3 |

| TD | ≤15 | |||

| Elongation @ break | MD | % | ≤300 | GN/T 1040.3 |

| TD | ≤300 | |||

| Wetting tension | - | mM/m | ≥38 | GN/T 14216 |

To increase the mechanical properties and add special functions to CPP (Cast Polypropylene) film, several methods can be employed. Here are some approaches:

Film Composition: Modify the composition of CPP film by incorporating additives or blending with other materials. Examples include:

Fillers: Add fillers such as calcium carbonate, talc, or glass fibers to enhance mechanical strength, stiffness, and dimensional stability.

Reinforcing Agents: Incorporate reinforcing agents like microfibers or nanoparticles to improve tensile strength, tear resistance, and impact resistance.

Compatibilizers: Use compatibilizers to improve the compatibility between CPP and other polymers or additives, enhancing mechanical properties and functionality.

Coating or Lamination: Apply coatings or laminates to the CPP film to add specific functions or properties. Some options include:

Barrier Coatings: Apply barrier coatings like metalized layers, oxide coatings, or polymer coatings to improve gas barrier properties, moisture resistance, or UV protection.

Adhesive Coatings: Apply adhesive coatings to enable heat-sealing properties or enhance bonding with other materials.

Functional Coatings: Apply specialized coatings such as anti-static, anti-fog, or antimicrobial coatings to add specific functionalities to the film.

Orientation: Orient the CPP film to improve its mechanical properties. Orientation can be achieved through processes such as stretching, biaxial stretching, or annealing. This can enhance tensile strength, heat resistance, tear resistance, and optical properties.

Cross-Linking: Cross-linking the CPP film can enhance its mechanical properties and thermal stability. Cross-linking can be accomplished through chemical methods like radiation cross-linking or through the addition of cross-linking agents during extrusion.

Blending: Blend CPP with other polymers or additives to modify its properties. For example:

Blending with Polyethylene (PE): Blending CPP with PE can improve impact resistance, flexibility, and processability.

Blending with Ethylene Vinyl Acetate (EVA): Blending CPP with EVA can enhance heat sealability and impact resistance.

Surface Treatment: Modify the surface properties of CPP film through treatments such as corona treatment, plasma treatment, or flame treatment. Surface treatment can improve wettability, adhesion, printability, or coating compatibility.

Nanostructured Films: Develop nanostructured CPP films by incorporating nanomaterials or utilizing nano-engineering techniques. This can lead to improved mechanical properties, barrier properties, or unique functionalities.

It's important to note that the specific methods and approaches to enhance CPP film properties may vary depending on the desired outcomes, application requirements, and manufacturing capabilities. It's recommended to consult with material scientists, polymer engineers, or film manufacturers to determine the most suitable strategies for achieving the desired mechanical properties and special functions for CPP film.