Wuhan Penta Chutian Laser Equipment Co., Ltd. |

|

Large-Format Fiber Laser Cutting Machine Range 2000w - 8000w Metal Laser Cutting Machine

Compared to backpack CO2 Laser Cutting Machine, the Bull has the advantages of power saving, fast moving, fast cutting, fast piercing and so on. The production efficiency is promoted more than 50%.

Adopt imported CNC and control software, YASKAWA servo motor, imported intelligent cutting head and some other high-level system, which guarantee the stability and advancement.

Laser protection and suction system adopted to guarantee operator's safety and clean environment.

Specification | Model |

| Bull8020/8035/10035/12035/16035/18035/20035... | |

| Table Travel | 4m~30m |

| Mechanical Accuracy(VDI 3441) | ±0.12mm/m |

| (Mechanical Repeatability) | ±0.1mm/m |

| Rapid Speed | 70m/min |

| Maximum Acceleration | 0.6G |

| Z Travel | 200mm |

| Laser Power Option | 2000W-8000W |

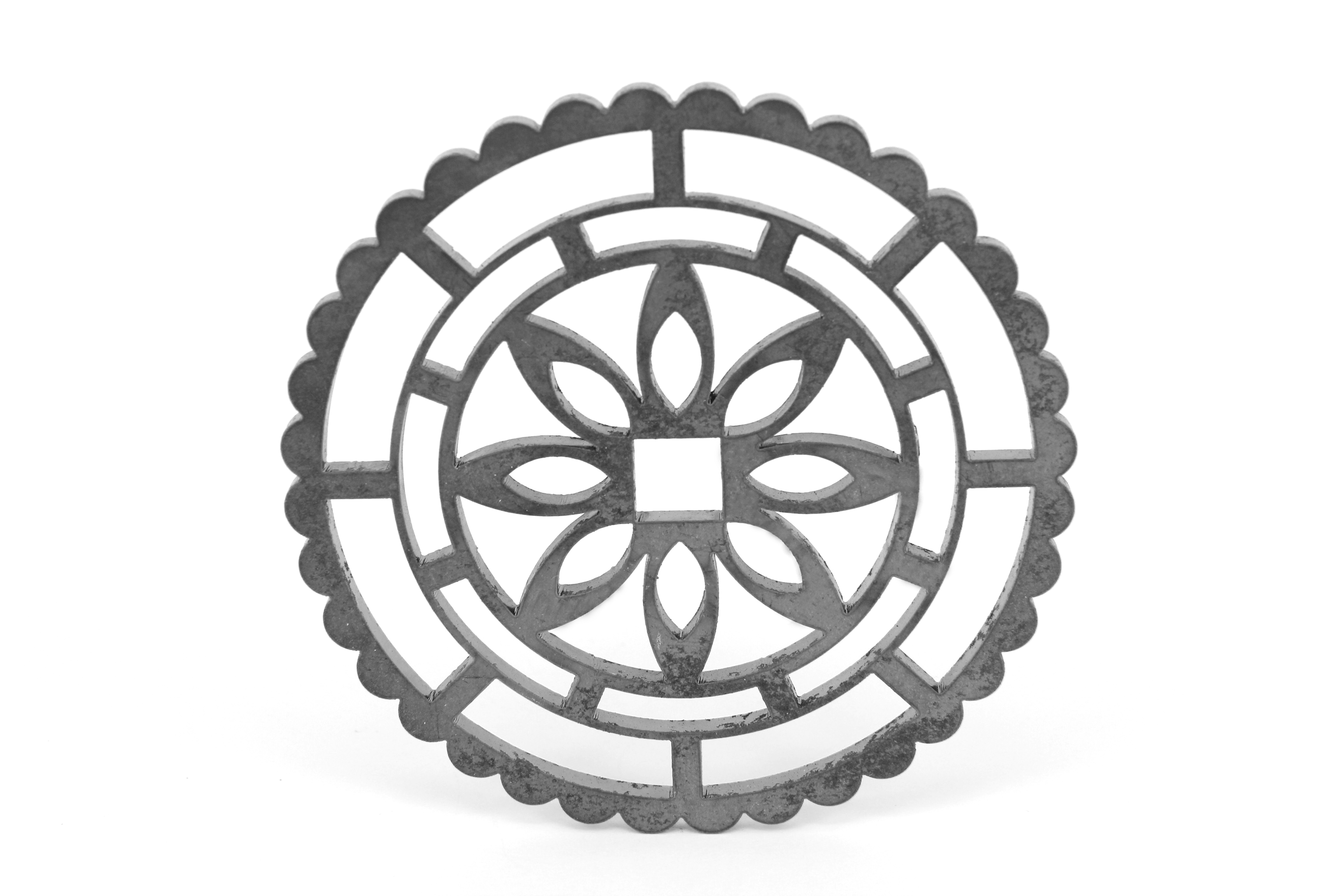

Applications

Widely used in metal processing industry like kitchenware, instrument, elevator panel,

tool processing, decoration, advertising andother manufacturing industries.

Samples

Our Advangages

Advanced CNC control

This Penta Chutian System is complete with is front-end software: Z32 Control System. This software has been developed within the Windows XP Professional environment. It eliminates the possibility of memory overrun.

The critical motion system remains housed in a PC based real time machine control, so that the expected performance and reliability is maintained. The merging of the control and the Windows ™ based PC is invisible to the operator.

The control easily facilitates graphic, conversational and conventional ISO formats for manual data input programming. The built in cutting database assists inexperienced operators to choose optimal cutting parameters including advance head set table to cut small hole on thick material (about half of the material thickness).

The system can also communicate with an off-line computer via Ethernet connection (cable and 2nd LAN board supplied by Penta Chutian-El.En).

Operation Software

The Smart Manager has been specifically developed to fully exploit

the new linear motor systems’ features, keeping the compatibility

of any other Penta Chutian’s product.

The new software generation includes many innovations introduced during the recent years in the industrial laser-cutting field (fast piercing, fast cutting speed on thick material etc…). The updated Users Interface (UI) improves the simplicity and immediacy of day-by-day operations while facilitating the most complicated laser cutting scenarios. The software is now more intuitive and easier to manage.

Among all the “standard” features of a CNC (Computer Numerical Controlled) dedicated to the laser cutting process, the Smart Manager offers a variety of enhancements and revolutionary solutions all aimed to speed up and simplify your laser job always keeping the tooling quality and safety to the maximum level.

Here are some of the more noteworthy features: