Jiangsu Ying Yan Fastening System Technology Co.Ltd |

|

Verified Suppliers

|

|

DIN471 Retaining Rings For Shafts - Normal Type Carbon Steel 65Mn Blacked,Parkerising Φ6-Φ200

Retaining Rings for Bores - Normal Type are a common type of fastener in mechanical design, primarily used to secure parts on axles, preventing them from moving or falling off. Here is an introduction to the characteristics, advantages, and applicable scenarios of this type of retaining ring:

Characteristics:

Advantages:

Applicable Scenarios:

In summary, retaining rings for bores - normal type are fasteners with simple structures, convenient installation, low costs, and strong adaptability, widely applied in various mechanical systems.

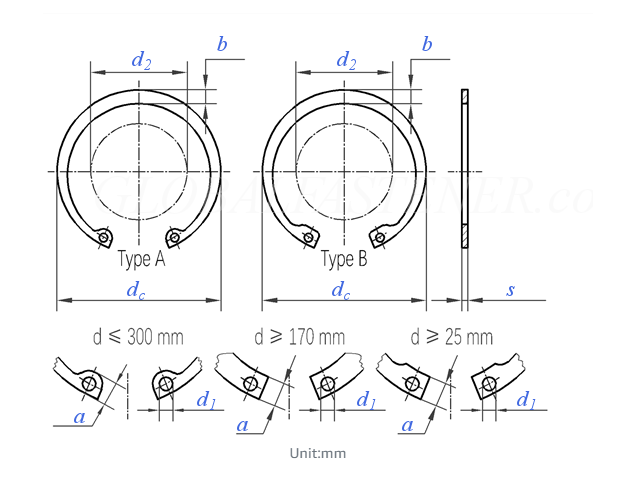

| Nominal Diameter | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

| d ① | ||||||||

| s | max | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 |

| min | 0.75 | 0.75 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |

| dc | max | 9.06 | 10.16 | 11.16 | 12.16 | 13.36 | 14.46 | 15.46 |

| min | 8.6 | 9.7 | 10.7 | 11.7 | 12.9 | 14 | 15 | |

| a | max | 2.4 | 2.5 | 3.2 | 3.3 | 3.4 | 3.6 | 3.7 |

| b | ≈ | 1.1 | 1.3 | 1.4 | 1.5 | 1.7 | 1.8 | 1.9 |

| d1 | min | 1 | 1 | 1.2 | 1.2 | 1.5 | 1.5 | 1.7 |

| d2 | 3 | 3.7 | 3.3 | 4.1 | 4.9 | 5.4 | 6.2 | |

| per 1000 units ≈ kg | 0.14 | 0.15 | 0.18 | 0.31 | 0.37 | 0.42 | 0.52 | |

| Nominal Diameter | 15 | 16 | 17 | 18 | 19 | 20 | 21 | |

| d ① | ||||||||

| s | max | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| min | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |

| dc | max | 16.56 | 17.66 | 18.72 | 19.92 | 20.92 | 21.92 | 22.92 |

| min | 16.1 | 17.2 | 18.17 | 19.37 | 20.37 | 21.37 | 22.37 | |

| a | max | 3.7 | 3.8 | 3.9 | 4.1 | 4.1 | 4.2 | 4.2 |

| b | ≈ | 2 | 2 | 2.1 | 2.2 | 2.2 | 2.3 | 2.4 |

| d1 | min | 1.7 | 1.7 | 1.7 | 2 | 2 | 2 | 2 |

| d2 | 7.2 | 8 | 8.8 | 9.4 | 10.4 | 11.2 | 12.2 | |

| per 1000 units ≈ kg | 0.56 | 0.6 | 0.65 | 0.74 | 0.83 | 0.9 | 1 | |

| Nominal Diameter | 22 | 24 | 25 | 26 | 28 | 30 | 31 | |

| d ① | ||||||||

| s | max | 1 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| min | 0.94 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | |

| dc | max | 23.92 | 26.32 | 27.32 | 28.32 | 30.6 | 32.6 | 33.9 |

| min | 23.37 | 25.69 | 26.69 | 27.69 | 29.85 | 31.85 | 33.15 | |

| a | max | 4.2 | 4.4 | 4.5 | 4.7 | 4.8 | 4.8 | 5.2 |

| b | ≈ | 2.5 | 2.6 | 2.7 | 2.8 | 2.9 | 3 | 3.2 |

| d1 | min | 2 | 2 | 2 | 2 | 2 | 2 | 2.5 |

| d2 | 13.2 | 14.8 | 15.5 | 16.1 | 17.9 | 19.9 | 20 | |

| per 1000 units ≈ kg | 1.1 | 1.42 | 1.5 | 1.6 | 1.8 | 2.06 | 2.1 | |

| Nominal Diameter | 32 | 34 | 35 | 36 | 37 | 38 | 40 | |

| d ① | ||||||||

| s | max | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.75 |

| min | 1.14 | 1.44 | 1.44 | 1.44 | 1.44 | 1.44 | 1.69 | |

| dc | max | 34.9 | 37 | 38.3 | 39.3 | 40.3 | 41.3 | 44.4 |

| min | 34.15 | 36.25 | 37.55 | 38.55 | 39.55 | 40.55 | 43.11 | |

| a | max | 5.4 | 5.4 | 5.4 | 5.4 | 5.5 | 5.5 | 5.8 |

| b | ≈ | 3.2 | 3.3 | 3.4 | 3.5 | 3.6 | 3.7 | 3.9 |

| d1 | min | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| d2 | 20.6 | 22.6 | 23.6 | 24.6 | 25.4 | 26.4 | 27.8 | |

| per 1000 units ≈ kg | 2.21 | 3.2 | 3.54 | 3.7 | 3.74 | 3.9 | 4.7 | |

| Nominal Diameter | 42 | 45 | 47 | 48 | 50 | 52 | 55 | |

| d ① | ||||||||

| s | max | 1.75 | 1.75 | 1.75 | 1.75 | 2 | 2 | 2 |

| min | 1.69 | 1.69 | 1.69 | 1.69 | 1.93 | 1.93 | 1.93 | |

| dc | max | 46.4 | 49.4 | 51.6 | 52.6 | 55.3 | 57.3 | 60.3 |

| min | 45.11 | 48.11 | 50.04 | 51.04 | 53.74 | 55.74 | 58.74 | |

| a | max | 5.9 | 6.2 | 6.4 | 6.4 | 6.5 | 6.7 | 6.8 |

| b | ≈ | 4.1 | 4.3 | 4.4 | 4.5 | 4.6 | 4.7 | 5 |

| d1 | min | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| d2 | 29.6 | 32 | 33.5 | 34.5 | 36.3 | 37.9 | 40.7 | |

| per 1000 units ≈ kg | 5.4 | 6 | 6.1 | 6.7 | 7.3 | 8.2 | 8.3 | |

| Nominal Diameter | 56 | 58 | 60 | 62 | 63 | 65 | 68 | |

| d ① | ||||||||

| s | max | 2 | 2 | 2 | 2 | 2 | 2.5 | 2.5 |

| min | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 2.43 | 2.43 | |

| dc | max | 61.3 | 63.3 | 65.3 | 67.3 | 68.3 | 70.3 | 73.6 |

| min | 59.74 | 61.74 | 63.74 | 65.74 | 66.74 | 68.74 | 72.04 | |

| a | max | 6.8 | 6.9 | 7.3 | 7.3 | 7.3 | 7.6 | 7.8 |

| b | ≈ | 5.1 | 5.2 | 5.4 | 5.5 | 5.6 | 5.8 | 6.1 |

| d1 | min | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 |

| d2 | 41.7 | 43.5 | 44.7 | 46.7 | 47.7 | 49 | 51.6 | |

| per 1000 units ≈ kg | 8.7 | 10.5 | 11.1 | 11.2 | 12.4 | 14.3 | 16 | |

| Nominal Diameter | 70 | 72 | 75 | 78 | 80 | 82 | 85 | |

| d ① | ||||||||

| s | max | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 |

| min | 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.92 | |

| dc | max | 75.6 | 77.6 | 80.6 | 83.8 | 86.8 | 88.8 | 91.8 |

| min | 74.04 | 76.04 | 79.04 | 81.96 | 84.96 | 86.96 | 89.96 | |

| a | max | 7.8 | 7.8 | 7.8 | 8.5 | 8.5 | 8.5 | 8.6 |

| b | ≈ | 6.2 | 6.4 | 6.6 | 6.8 | 7 | 7 | 7.2 |

| d1 | min | 3 | 3 | 3 | 3 | 3 | 3 | 3.5 |

| d2 | 53.6 | 55.6 | 58.6 | 60.1 | 62.1 | 64.1 | 66.9 | |

| per 1000 units ≈ kg | 16.5 | 18.1 | 18.8 | 20.4 | 22 | 24 | 25.3 | |

| Nominal Diameter | 88 | 90 | 92 | 95 | 98 | 100 | 102 | |

| d ① | ||||||||

| s | max | 3 | 3 | 3 | 3 | 3 | 3 | 4 |

| min | 2.92 | 2.92 | 2.92 | 2.92 | 2.92 | 2.92 | 3.9 | |

| dc | max | 94.8 | 96.8 | 98.8 | 101.8 | 104.8 | 106.8 | 109.3 |

| min | 92.96 | 94.96 | 96.96 | 99.96 | 102.96 | 104.96 | 107.46 | |

| a | max | 8.6 | 8.6 | 8.7 | 8.8 | 9 | 9.2 | 9.5 |

| b | ≈ | 7.4 | 7.6 | 7.8 | 8.1 | 8.3 | 8.4 | 8.5 |

| d1 | min | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| d2 | 69.9 | 71.9 | 73.7 | 76.5 | 79 | 80.6 | 82 | |

| per 1000 units ≈ kg | 28 | 31 | 32 | 35 | 37 | 38 | 55 | |

| Nominal Diameter | 105 | 108 | 110 | 112 | 115 | 120 | 125 | |

| d ① | ||||||||

| s | max | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | |

| dc | max | 113.3 | 116.3 | 118.3 | 120.3 | 123.5 | 128.5 | 133.5 |

| min | 111.46 | 114.46 | 116.46 | 118.46 | 121.37 | 126.37 | 131.37 | |

| a | max | 9.5 | 9.5 | 10.4 | 10.5 | 10.5 | 11 | 11 |

| b | ≈ | 8.7 | 8.9 | 9 | 9.1 | 9.3 | 9.7 | 10 |

| d1 | min | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 4 |

| d2 | 85 | 88 | 88.2 | 90 | 93 | 96.9 | 101.9 | |

| per 1000 units ≈ kg | 56 | 60 | 64.5 | 72 | 74.5 | 77 | 79 | |

| Nominal Diameter | 130 | 135 | 140 | 145 | 150 | 155 | 160 | |

| d ① | ||||||||

| s | max | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | |

| dc | max | 138.5 | 143.5 | 148.5 | 153.5 | 159.5 | 165.5 | 170.5 |

| min | 136.37 | 141.37 | 146.37 | 151.37 | 157.37 | 163.37 | 168.37 | |

| a | max | 11 | 11.2 | 11.2 | 11.4 | 12 | 12 | 13 |

| b | ≈ | 10.2 | 10.5 | 10.7 | 10.9 | 11.2 | 11.4 | 11.6 |

| d1 | min | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| d2 | 106.9 | 111.5 | 116.5 | 121 | 124.8 | 129.8 | 132.7 | |

| per 1000 units ≈ kg | 82 | 84 | 87.5 | 93 | 105 | 107 | 110 | |

| Nominal Diameter | 165 | 170 | 175 | 180 | 185 | 190 | 195 | |

| d ① | ||||||||

| s | max | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | |

| dc | max | 176 | 181 | 186.2 | 191.2 | 196.2 | 201.2 | 206.2 |

| min | 173.87 | 178.87 | 183.78 | 188.78 | 193.78 | 198.78 | 203.78 | |

| a | max | 13 | 13.5 | 13.5 | 14.2 | 14.2 | 14.2 | 14.2 |

| b | ≈ | 11.8 | 12.2 | 12.7 | 13.2 | 13.7 | 13.8 | 13.8 |

| d1 | min | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| d2 | 137.7 | 141.6 | 146.6 | 150.2 | 155.2 | 160.2 | 165.2 | |

| per 1000 units ≈ kg | 125 | 140 | 150 | 165 | 170 | 175 | 183 | |

| Nominal Diameter | 200 | 210 | 220 | 230 | 240 | 250 | 260 | |

| d ① | ||||||||

| s | max | 4 | 5 | 5 | 5 | 5 | 5 | 5 |

| min | 3.9 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | |

| dc | max | 211.2 | 223.7 | 233.7 | 243.7 | 254 | 264 | 277 |

| min | 208.78 | 221.28 | 231.28 | 241.28 | 251.19 | 261.19 | 274.19 | |

| a | max | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 16.2 |

| b | ≈ | 14 | 14 | 14 | 14 | 14 | 14 | 16 |

| d1 | min | 4 | 4 | 4 | 4 | 4 | 4 | 5 |

| d2 | 170.2 | 180.2 | 190.2 | 200.2 | 210.2 | 220.2 | 226 | |

| per 1000 units ≈ kg | 195 | 270 | 315 | 330 | 345 | 360 | 375 | |

| Nominal Diameter | 270 | 280 | 290 | 300 | ||||

| d ① | ||||||||

| s | max | 5 | 5 | 5 | 5 | |||

| min | 4.88 | 4.88 | 4.88 | 4.88 | ||||

| dc | max | 287 | 297 | 307 | 317 | |||

| min | 284.19 | 294.19 | 304.19 | 314.19 | ||||

| a | max | 16.2 | 16.2 | 16.2 | 16.2 | |||

| b | ≈ | 16 | 16 | 16 | 16 | |||

| d1 | min | 5 | 5 | 5 | 5 | |||

| d2 | 236 | 246 | 256 | 266 | ||||

| per 1000 units ≈ kg | 388 | 400 | 415 | 435 | ||||