QINGDAO AORUI PLASTIC MACHINERY CO.,LTD1 |

|

Verified Suppliers

|

|

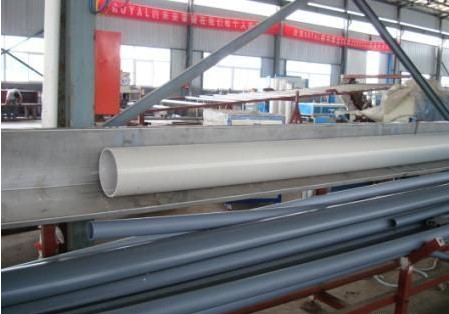

Double Screw PVC Pipe Making Machine , Plastic PVC Water Pipe Production line

Quick detail

1. Adopting two sets of conial twin-screw extruder with reverse outward rotation, Co-extrusion die, spiral grooved core-rod for option roder to produce foam core pipe with in-wall and hollow wall pipe with screw thread. Adopting vacuum calibrating and spray cooling baths, accurate calibration, fast cooling. The baths are made of stainless steel.

2. SJSZ series plastic pipe production line is mainly used in manufacture of the plastic PVC pipes with tube diameters and wall thickness, which are used for water supply and drainage/electric conduict pipe in the field of agriculture and construction.This line is composed of conical twin-screw extruder, vacuum calibration table, haul-off, cutter, stacker etc.The extruder and the haul-off adopt the quality AC frequency conversion control device.The vacuum pump and motor adopt the famous brand.The haul-off have two-claw, three-claw, four-claw, six-claw. It may choose the saw blade cutting type or the planet cutting production efficiency.

Description:

Features of this line:

1. high efficiency single screw extruder: high rotating speed, good compounding effect and stable extrusion ensuring big capacity.

2. extruding die: adopting latest designed die head with spiral distributing flow channel, built-in temperature controlling device which make the extrusion more evenly.

3. vacuum calibrating tank: advanced water loop vacuum calibration, two vacuum chambers ensuring perfect roundness of the pipe, multi-section 6 meter water spraying tank, make sure cooling the pipe thoroughly, the main body of the tank made of stainless steel.

4. haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

5. cutting unit: dust-free cutting, with PLC controlling and meter counter.

6. stacking unit: providing pipe winder or pipe stacker.

7. controlling system: supply manual controlling cabinet and SIEMENS PLC touch screen controlling.

Main Technical Parameter

| Specification | GF63 | GF110 | GF160 | GF250 | GF400 | GF630 | GF800 |

| Item | diameter 16-63 | diameter 16-110 | diameter 32-160 | diameter 63-250 | diameter 160-400 | diameter 315-630 | diameter 450-800 |

| Diameter of pipe material | 16-63 | 16-110 | 32-160 | 63-250 | 160-400 | 315-630 | 450-800 |

| claw number of drawing machine | 2 | 2 | 2 | 3 | 4 | 6 | 8 |

| pulling force | 6 | 8 | 11 | 20 | 30 | 40 | 50 |

| drawing speed | 15 | 12 | 8 | 9 | 4 | 2 | 2 |

| total power of auxiliary machine | 14 | 14 | 14 | 21.5 | 41 | 56 | 64 |

Application:

With special device , it can produce inner wall sprial pipe, inner wall hollow pipe, and core layer bulpo pipe , etc. it can also produce PP , PE ,ABS , &PPR , PEX , silicon core pipe and pipe material of other material. The planet-shaped cutting machine is fully automatic conputer digital control , it has such advantages of simple operation , reliable property , etc.it has reached world advanced level.

Our competetive advantages:

1) We give you suitable suggestions according to your actual need.

2) Technical support: available lifelong

3) Under the right operation way, the screw and barrel is for 10000

working hours.

4) Our expert will answer any inquiry within 48 hours and it will

be solved as soon as possible.

5) The customer can send the engineer to our company with training

6) Our engineer can be to the Buyer's company for installation and

testing the lines.

7) The seller provides you with complete technical support

documents and the relative drawings of the electric components

written in Chinese and English.