Ningbo Shuangde Tianli Machinery Manufacturing Co., Ltd. |

|

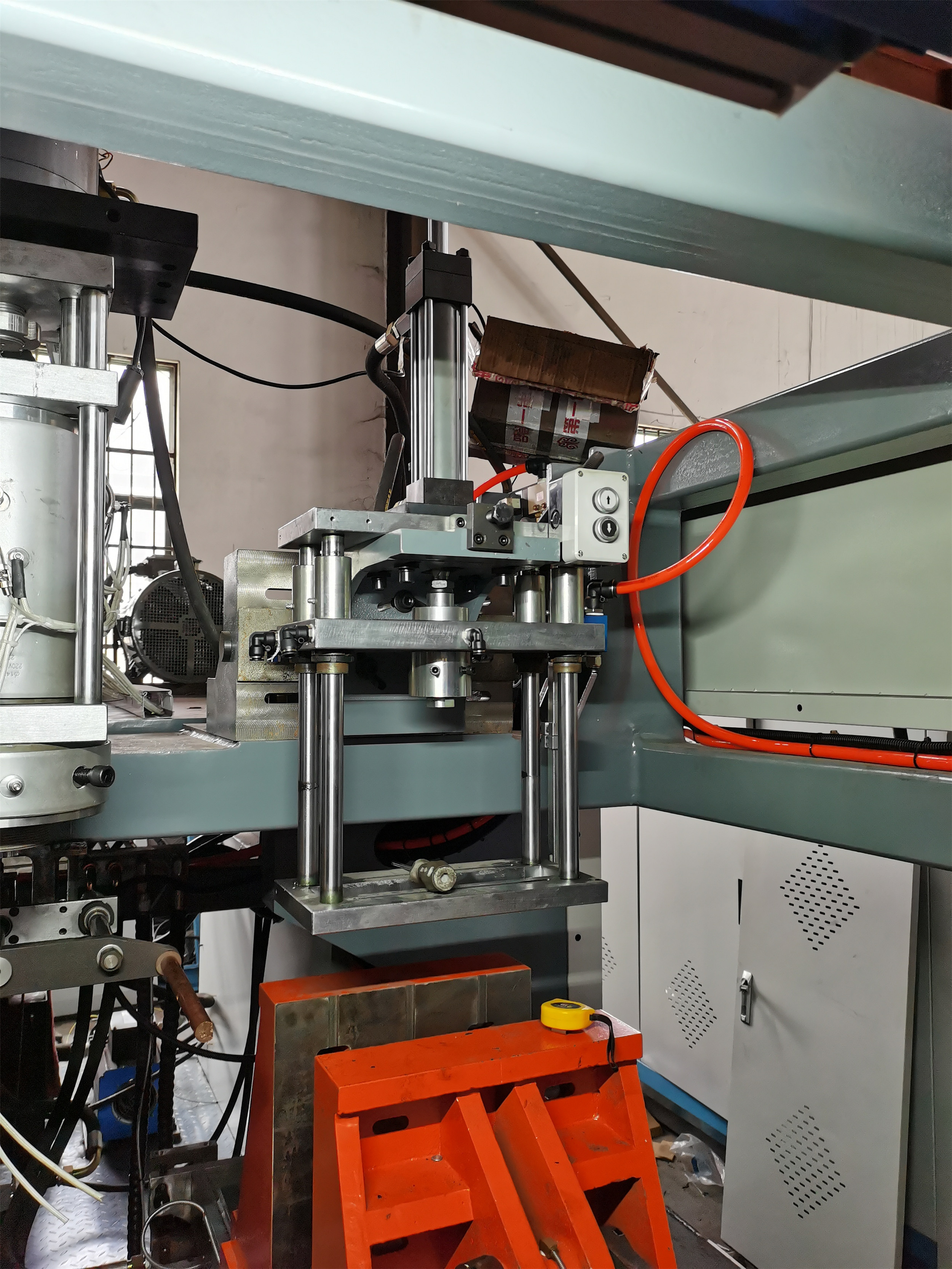

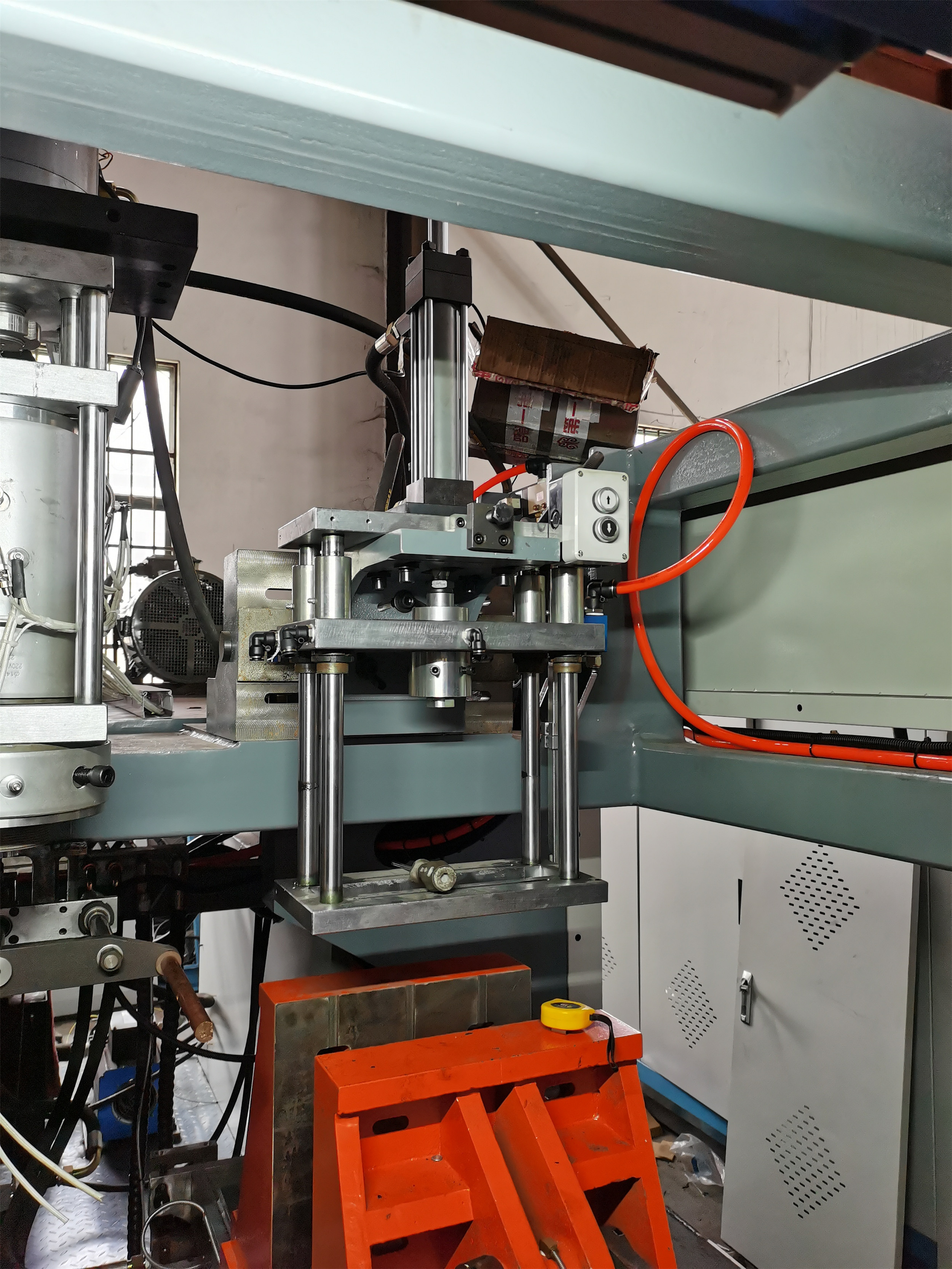

HDPE High Speed 2 Layers Automatic Extrusion Blow Molding Machine for Plastic Chemical Containers

SLBU series:

1: this machine is suitable for the production of 200ML 10L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speedF aster, run more smoothly.

2: die opening and closing system: specially designed for Heng lock mould mechanism using a high pressure mode locking, locking plate stress in the centre of the template, clamping force, openThe rigid lock template, even if the ultra wide die is also fitted.

3: die head system: all the use of 38CRMOALA and other materials, the precision machining and heat treatment.

4:Automatic blow molding machine is a very common production machine, widely used in the production of plastic bottles in related industries. The automatic blow molding machine will inevitably encounter some deviation problems when it is fully automatic production, and it is also appropriate to cause the weight of the blowing bottle to be different. After all, automatic blow molding machine will inevitably have some minor errors. But we have to look for other objective reasons besides these subjective factors, because these objective reasons seriously affect the accuracy of blowing bottle weight.

| SPECIFICATION | SLBU-80 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 10 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 950x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4600x2600x2600 |

| TOTAL WEIGHT | TON | 7.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 86 |

| PLATEN OPENING STROKE | MM | 300-600 |

| PLATEN SIZE(WxH) | MM | 450x450 |

| MAX MOULD SIZE(WxH) | MM | 500x450 |

| MOLD THICKNESS | MM | 305-400 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 80 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 120 |

| BARREL HEATING POWER | KW | 20 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 30 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 160 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 260 |

| POWER | ||

| MAX DRIVE POWER | KW | 35 |

| TOTAL POWER | KW | 82 |

| FAN POWER OF SCREW | KW | 3.2 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.5 |

| AVERAGE ENERGY CONSUMPTION | KW | 22 |