Zhangjiagang U Tech Machine Co., Ltd |

|

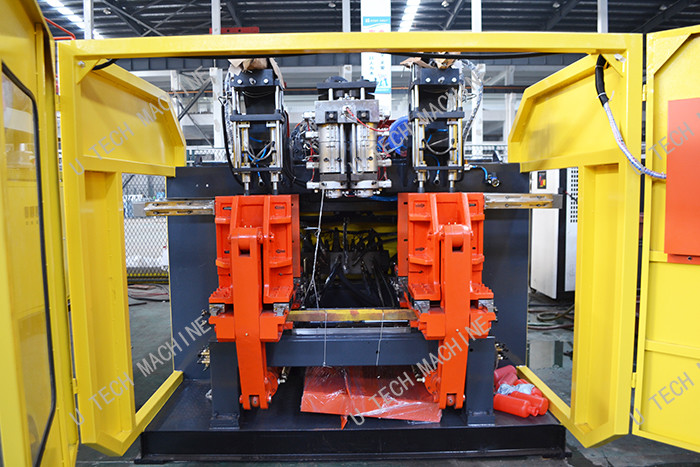

HDPE Bottles Jerry Can Blow Molding Machine View Stripe Line 5L

Stackable Jerry Can Making Machine

Introduction

This model adopts fixed mould open-closing system and accumulator

die.This model is automatic process with low noise, saving energy,

high efficiency, safe operation, easy maintenance and other

benefits. This model is widely used to produce chemical barrel,

auto parts(water box, oil box, air-condition pipe, aoto tail), toys

(wheel, hollow autobike, basketball stands, baby castle), tool box,

vacuum cleaner pipe, chairs for bus and gymnasium,etc.This model

can produce max 5L hollow plastic product.

Specifications:

Parameter

SPECIFICATIONS & TECHNICAL DATA | |||

Extrusion Unit | Screw Diameter | mm | 80 |

Plasticizing Capacity | Kg/hour | 110 | |

Temperature Control Zone | No. | 5 | |

Continuous Head | Single Head Max Die Diameter | mm | 230 |

Double Head Central Distance | mm | 230 | |

Four Head Central Distance | mm | 120 | |

Six Head Central Distance | mm | 85 | |

Clamping Unit | Clamping Force | KN | 110 |

Platen Size | mm | 580x420 | |

Opening Distance | mm | 150~450 | |

Moving Distance | mm | 720 | |

Max Mould Size | mm | 630x385 | |

Driving System | Extrusion Motor Power | KW | 30 |

Pump Motor Power | KW | 15 | |

Machine Total Power | KW | 72 | |

Average Power Consumption | KW | 42 | |