Ningbo Qiming Machinery Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

SPECIALIZED DESIGN FOR ELECTRONIC & MEDICAL PRODUCTS WITH COMPETITIVE PERFORMANCE AGAINST FULL ELECTRIC MACHINES

MZ series is a replacement of all electric injection machines for electronic and medical products which require high performance from the machines. It has been used and approved in numerous costumers for the application.

HYDRAULIC SYSTEM

The hydraulic valves are set adjacent to all the oil cylinders for rapid oil transfer. The hydraulic devices is installed outside for easy maintenance. The pressure and flow are controlled by closed-loop. The pre-injection ratio valves can be controlled easily and accurately. The hydraulic system control technology is incorporated with reliable international manufacturers.

BETTER MOLDING STABILITY

Moving platen is equipped with flowing bearing system, which raises the efficiency of open/close mold and reduces the energy consumption. Five points vertical double toggle clamping system provides precise and fast movement. T-slot is made for convenience of mold installment. Also, MZ- series can adjust the mold automatically according to the preset clamping force. It is installed with cavity oil cylinder required with high speed movements, which can alleviate the impact force.

INJECTION SYSTEM

MZ series adopts high quality linear guider to ensure accurate injection. Also, the injection system adopts double oil circuits to satisfy fast injection speed for high precision products.

Paramaters:

INJECTION UNIT |

| MZ-130 | |

SCREW DIAMETER | mm | 25 | 28 |

SCREW L/D RATIO | l/d | 20 | 19 |

THEORETICAL SHOT VOLUME | cm3 | 98 | 123 |

SHOT WEIGHT(PS) | g | 90 | 113 |

oz | 3.2 | 4 | |

INJECTION STROKE | mm | 200 | |

INJECTION PRESSURE | kg/cm2 | 3650 | 2910 |

THEORETICAL INJECTION SPEED | mm/sec | 423 | |

MAX. INJECTION RATE | g/sec | 191 | 240 |

MAX. SCREW RPM | rpm | 320 | |

NOZZLE SEALING FORCE | ton | 4.5 | |

NOZZLE ADVANCE STROKE | mm | 380 | |

CLAMPING UNIT | |||

CLAMPING FORCE | kn | 1300 | |

MOLD OPENING STROKE | mm | 410 | |

MAX. DAYLIGHT BETWEEN PLATENS | mm | 910 | |

MIN. MOLD THICKNESS | mm | 150 | |

MAX. MOLD THICKNESS | mm | 500 | |

DISTANCE BETWEEN THE TIE BAR (HXV) | mm | 460×460 | |

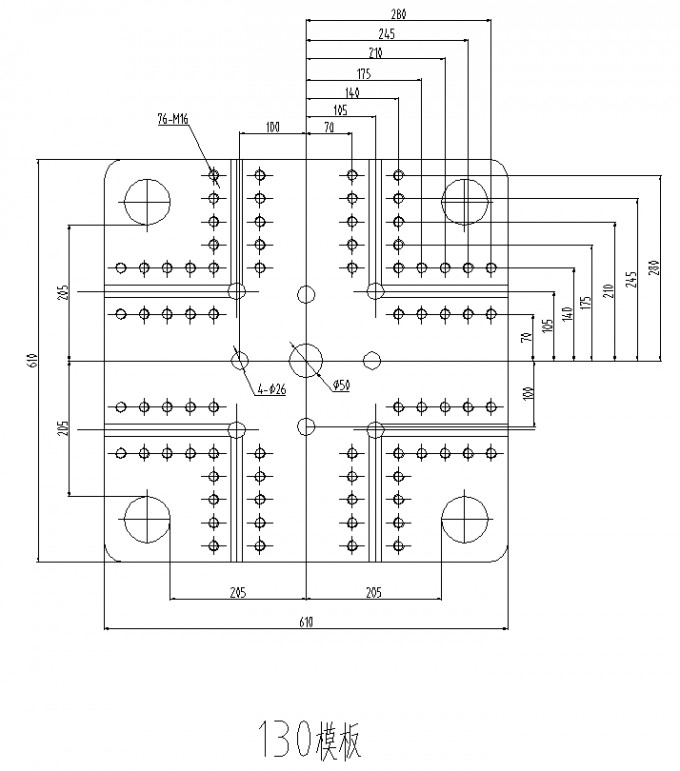

OVERALL SIZE OF PLATENS (HXV) | mm | 675×675 | |

EJECTION FORCE | kn | 38 | |

EJECTION STROKE | mm | 140 | |

OTHERS | |||

BARREL HEATER CAPACITY | Kw | 6.5 | |

MAX.PUMP PRESSURE | mpa | 17.5 | |

ELECTRIC MOTOR CAPACITY | Kw | 15+15 | |

OIL TANK CAPACITY | L | 300 | |

DIMENSIONS OF MACHINE (LXWXH) | m | 5.1×1.4×1.7 | |

WEIGHT OF MACHINE | T | 5.3 | |