Kaiping Zhonghe Machinery Manufacturing Co., Ltd |

|

Verified Suppliers

|

|

excav parts long reach boom excavator Telescopic Arm Dipper Stick excavator long reach arm customized telescopic excavator

2024 Zhonghe Machinery Catalogue 3M.pdf

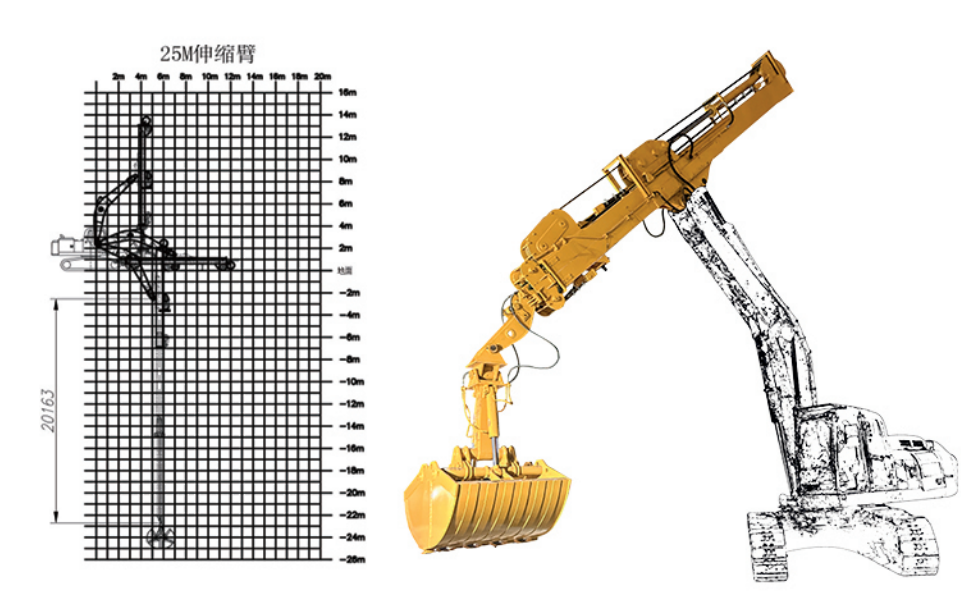

Three-section excavator telescopic arm

A three-section telescopic boom excavator refers to an excavator equipped with an arm composed of three telescopic sections. Each section of the arm can be extended or retracted independently, allowing the excavator to reach greater reach and depth.

The telescopic boom design provides the excavator with greater flexibility and versatility as it can adjust the length of the boom to the specific requirements of the job. By extending or retracting the telescoping section, the excavator can dig deeper or extend its reach horizontally without having to reposition the entire machine.

Three-section telescopic boom configurations are commonly used in a variety of construction and excavation applications. It offers advantages in tasks such as digging trenches, digging foundations, and climbing over obstacles or buildings. Telescopic arms provide additional reach and digging depth compared to standard excavator arms, making them useful when access is limited or when working on uneven terrain.

It’s worth noting that the specific functions and features of an excavator telescopic boom may vary by manufacturer and model. Different excavators may have different working ranges and lifting capabilities, so be sure to check the specifications of your specific machine to fully understand its capabilities.

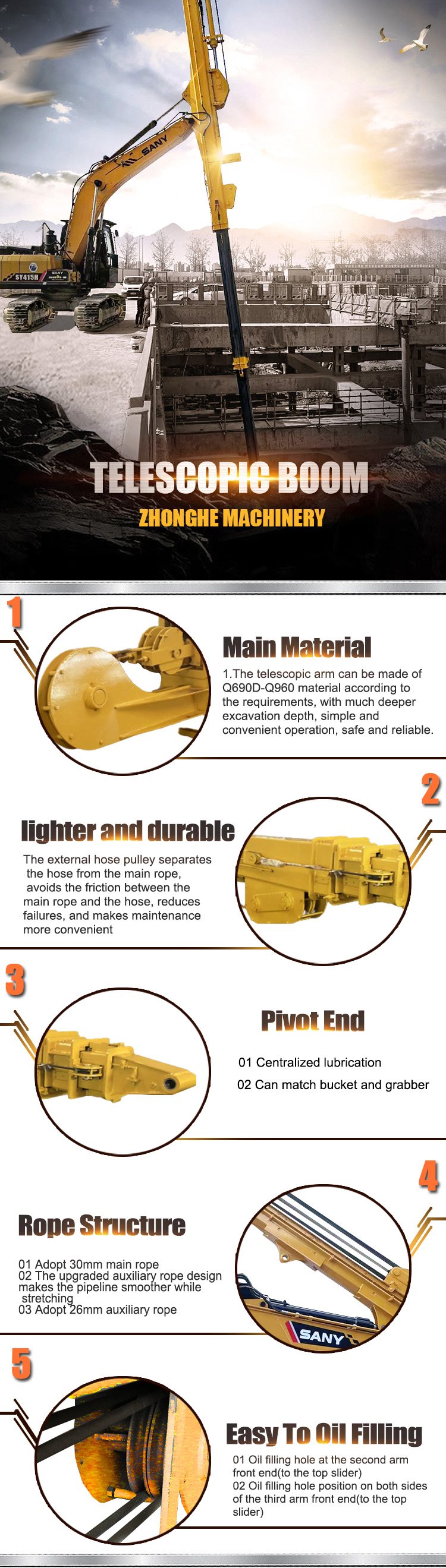

Advantages of excavator telescopic arm

Advantage 1: The external hose pulley separates the hose from the main rope, avoiding friction between the main rope and the hose, reducing failures and making maintenance more convenient.

Advantage 2: Using 30mm main rope. Use 26mm auxiliary rope.

Upgraded auxiliary rope design to make pipe stretching smoother

Advantage 3: The external hose pulley separates the hose from the main rope, avoiding friction between the main rope and the hose, reducing failures and making maintenance more convenient.

Advantage 4: The oil filling hole is at the front end of the second

arm (to the upper slider).

The refueling holes are located on both sides of the front end of

the third arm (to the top slider)

Three-section telescopic arm

The main material we choose is Q690/HG785

lighter and stronger

The main material of the arm tube we use is Q690D/HG785

Extended life, lighter, stronger

Another place we use Q355B.

telescopic arm

Nylon material to reduce wear

Our pulleys are made of POM material, which has high mechanical

strength and rigidity.

Two sliding wheels are at the top and two others at the bottom,

this part separates the high and low parts.

The pressure hose and steel wire rope reduce mutual friction. Less

friction can extend the service life. You can see the top is the

wire rope and the bottom is the high pressure hose on either side.

Additionally, there is an adjustable bracket here to tighten the

hose as needed.

Excavator (Ton) | Max Depth (mm) | Effective Length (mm) | Bucket Capacity (mm) |

| 6-10 | 10000 | 7600 | 0.2-0.3 |

| 11-15 | 14000 | 10500 | 0.4-0.6 |

| 20-30 | 16000 | 12500 | 0.8-1.5 |

| 30-35 | 20000 | 15500 | 1.3-1.66 |

| 30-35 | 25000 | 20500 | 1-1.4 |

| 40-45 | 25000 | 20500 | 1.8-2.5 |

| 40-45 | 30000 | 25100 | 1.4-2 |

The first system is the technical design drawing review mechanism,

The second system is the semi-finished product review mechanism,

(each process has a detection testing for the previous process)

The third system is the finished product testing.

(Before painting, the overall inspection is carried out to check whether the design size matches the welding size, and whether the installation size meets the design requirement.)

To sum up, every single ZHONGHE product has been passed the above three-stage inspection system to ensure that is qualified before shipping.

1. 14,000 square metres of plant

We have more than 14000 square metres of steel structure standard factory and a large number of high-precision processing equipment.

2. High-tech R&D team

We use sophisticated drawing software to achieve the maximum work

envelope while operating safely.

3. Experienced Staff

We have more than 60 skilled employees, including 30 welders with more than 5 years of welding experience.

4. Customisation

(1) Matching with various brands of excavators.

(2) Colours, lengths and materials can be customised according to

your requirements.

(3) Extra pipes can be added to suit some additional applications.

5. Timely delivery

(1) Our delivery time is 7-15 days.

(2) The annual production capacity is 600 sets of various types of

excavator arms.

6. 100% service

(1) 24 hours online support.

(2) Video technical support by appointment. (Our engineers have

been specialising in excavator arms and attachments for more than

10 years)

Translated with DeepL.com (free version)

Our products have CE certificates, you can completely trust the quality of our products.

Shipping and packaging

Our products have been sold to more than 60 countries, and our transportation methods include sea transportation, land transportation, and air transportation. Our packaging is wooden box packaging or stretch film packaging. The goods will be packed before shipment and then loaded into the container to ensure the safety of the goods.

Q1.How much is the payment?

A:Bank transfer and PayPal are both available, if you prefer other methods, they can also be negotiated.

Q2.Will it fit my excavator?

A.certainly. We will make the connection the same size as your machine so it will fit perfectly.

Q3. How long does delivery take?

A.It depends on the destination port. Usually production and delivery takes 7 to 30 days.

Q4. What are the payment terms?

A: Western Union, T/T, Trade Assurance are acceptable.

Q4. Where is your factory located?

A: No. 9, Huancui West Road, Cuishanhu New District, Kaiping City,

Guangdong Province, China

Any details, welcome to contact me.

| Contact | Ada |

| Whatsapp/Tel | 0086 15322105263 |

| abby@excavatorboomarm.com | |

| Excavator Rock Bucket |