Sinuo Testing Equipment Co. , Limited |

|

Verified Suppliers

|

|

IEC 62196 Electric Vehicle IPX9K Water Ingress Testing Chamber

Complied Standards & Clauses

IEC 62196-1Ed.4CDV 2020 clause 20.2

IEC 60529:1989 + A1:1999 + A2:2013 Clause 14.2.9

DIN40050-9

ISO20653

Equipment Overview

This test chamber conforms to:IEC 60529:1989 + A1:1999 + A2:2013 Clause 14.2.9, and required by IEC 62196-1Ed.4CDV 2020 clause 20.2, DIN40050-9, ISO20653 IP degrees of protection provided by enclosures for the electrical equipment in road vehicles for protecting the electrical equipment inside the enclosure against the effects of the ingress of solid foreign objects, including dust (protection against foreign objects),protecting the electrical equipment inside the enclosure against the effects of the ingress of water (protection against water).

Application:

It is used to inspect the enclosures of the electrical equipment (IP supplementary code test), and it is applicable for waterproof testing of the electrical and auto parts under high temperature and high pressure.

Test sample:

Products should pass IPX9 degrees waterproof test, such as automotive and motorcycle parts, electrical and electronic industries.

Material and Structural:

Outside enclosure and inner chamber all are made of SUS304 stainless steel, the upper part of the test chamber is for testing and the control, the lower part of the test chamber consists of imported Italian high-pressure pump and solenoid valve, constant temperature and backwater tanks (SUS304 stainless steel), turntable motor (Panasonic motor) and deceleration transmission mechanism.

All control settings, water temperature, nozzle control, pressure, time, flow requirements can be controlled by PLC and set on 7 "Taiwan WEINVIEW touch screen or a higher industrial control component touch screen.

1. The test chamber consists of test room, water storage tank, control part, product dewatering buffer area, and jet system.

2. Inner chamber size: L 1000MM * W 1000MM*H 1000MM.

3. Outside chamber size: L 1500MM * W1200MM * H 1950MM.

4. Jet system: Composed by the high pressure high temperature water pump, high pressure high temperature water pressure meter, high pressure high temperature solenoid valve, high pressure high temperature hydraulic pipe.

5. Pipe diameter: 3/4”.

6. Jet nozzle :4 pcs.

7. Hot water jet temperature: RT~80°C±5°C. (Adjustable, enhanced temperature and water overflow protection)

8. Jet water pressure: 80 ~ 100bar (8000 ~ 10000Kpa, 81.5-101.9kg/c㎡)

9. Water jet flow: 15±1 L / min(14-16L/min)

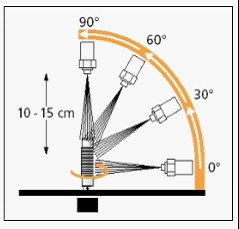

10. Jet distance: 100-200mm and can be adjustable nozzle distance by manual

11. Water jet angle: 0 °, 30 °, 60 °, 90 ° (The testing angle can be adjustable by manual), based on a horizontal line, distribute nozzle hole at anticlockwise ±0° ±30° ±60° ±90° with valve on nozzle, can set programmable to jet in turn.

12. Test time: each angle water jet 30 seconds as per standard requirements, but our system can achieve 0~90s pre-settable and adjustable.

13. Turntable: The product needs to be placed on a turntable, bearing capacity: ≤30Kgs.

14. Turntable speed :5-17r/min (motor drives turbine slow rotating, control speed and adjust to appropriate speed by frequency converter)

15. Turntable diameter: Φ500mm

16. Run time control: 1min ~ 9999min (pre-settable and adjustable).

17. Water circulation system to ensure the use of water recycling.

18. Water jet surface: Front of the product.

19. Jet pressure gauge: can display water pressure.

20. Control system: Independent research and development touch screen control system.

21. Use the tempered glass as a waterproof wall of the outside chamber, and stainless-steel square as the bracket.

22. The chamber door: large screen visual tempered glass door, observing test condition and time and equipped with a wiper.