Guangzhou Ailusi Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Hydraulic lifting vacuum emulsifying mixer: The machine is suitable for the production of various kinds of paste, cream products in cosmetic factory and pharmaceutical factory. Especially designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpastes, etc. having extremely small particles for chemical, cosmetics, pharmaceutical and food industrie

Item:China maker body cream lotion machine | Application: | Liquid with Suspended Solids, liquid wash, cosmetic beauty cream, shampoo, detergent etc |

| Function: | Mixing and homogenizing | |

| Additional Capabilities: | Milling | |

| Mixer Type: | Homogenizer | |

| Homogenizer: | Bottom homogenizer with frequency inverter | |

| Mixing: | Upper frame oar scrape mixer | |

| Max. Loading Capacity: | 50-5000L | |

| Dimension(L*W*H): | 3100*1750*3400mm | |

| Voltage: | 380V/50Hz | |

| Power(W): | 75KW | |

| Heating method: | Electric heating / steam heating | |

| Control: | Siemens PLC brand | |

| Structure: | Water tank, oil tank, emulsifying tank, platform and cabinet | |

| Material: | SUS304 & SUS316L (3 layers) | |

| Certification: | CE | |

| Warranty: | One year since the date of installation. |

Item NO.:AVE

Lead Time:35 days

Product Orgin:China

Shipping Port:Yangzhou/Guangzhou

Payment:EXW, FOB, CIF etc

MOQ:1

goods stock:500

Product Detail

Consisting of material filter, vacuum pressure meter, vacuum discharge valve, vacuum inlet, positive pressure inlet, CIP system (Spray ball), sight glass light, sight window, man-hole, hopper.

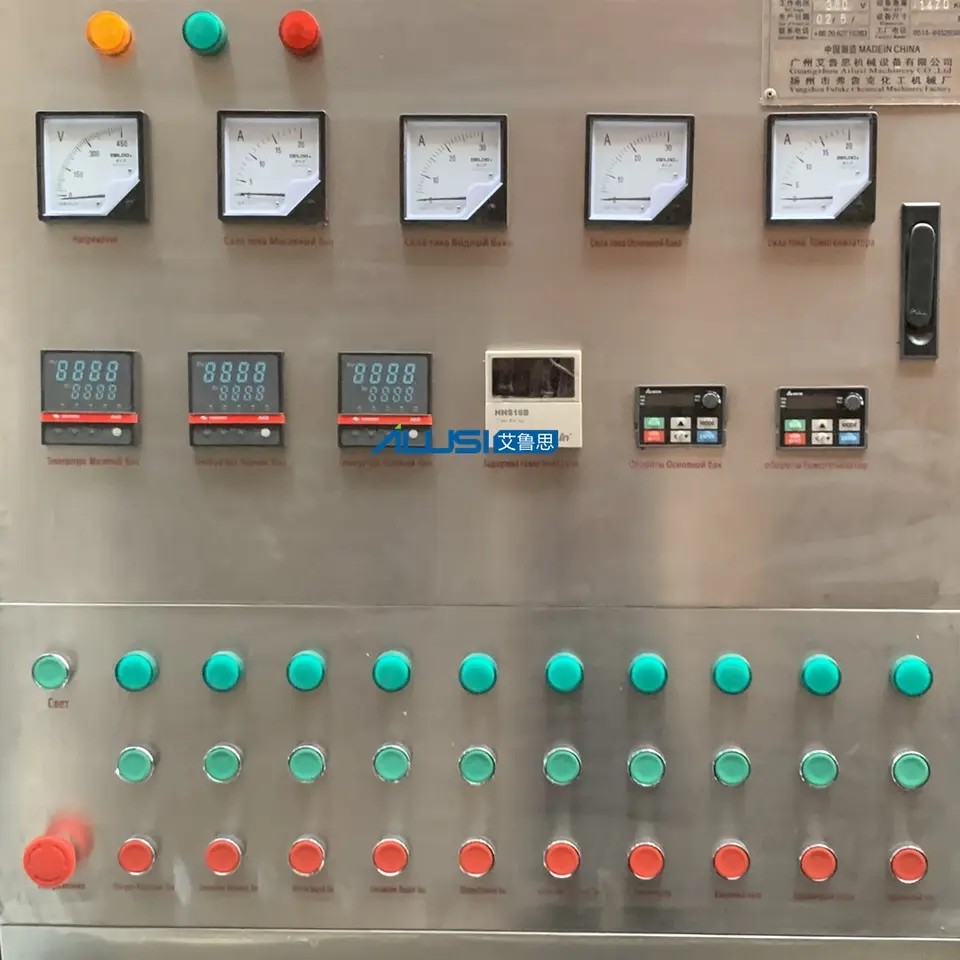

Outer layer material: adopt SUS304 Stainless steel plate, Meter: thermometer, Time digital display met, Current voltmeter Button: Each function switch control button or famous brand Siemens touch screen, Power indicator light, scram etc. The electrical components:include various control relay.

Name: Hygiene grade mirror polish & SUS304&316L, Half open lid, easy for operation; Jacket Electric heating; High shearing disperser plate; Disperser on bottom Water pot and oil pot drainer pipe connect to one outlet.

Frame wall scrapping blender Stirrer paddle: SUS316L, Scraper blade: white PTFE material

Rotor and stator adopts wire-cutting finish machining high shearing homogenizer, smooth emulsion to 2μm.

Factory:

After-sales Service: Online support,Video technical support,Free spare parts

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2: How does your factory do regarding quality control?

A2: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3: What’s the guarantee and the after service if we purchase from you?

A3: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4: Are your machines difficult to operate? How do you teach us to use the machine?

A4: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5: Can you make the machine according to customers' request?

A5: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.