Guangzhou Ailusi Machinery Co., Ltd. |

|

Verified Suppliers

|

|

A semi-automatic multi-function capping machine is a packaging

machine that is used to cap various types of containers, including

bottles, jars, and cans. The machine is designed to automate part

of the capping process while still requiring some manual

intervention.

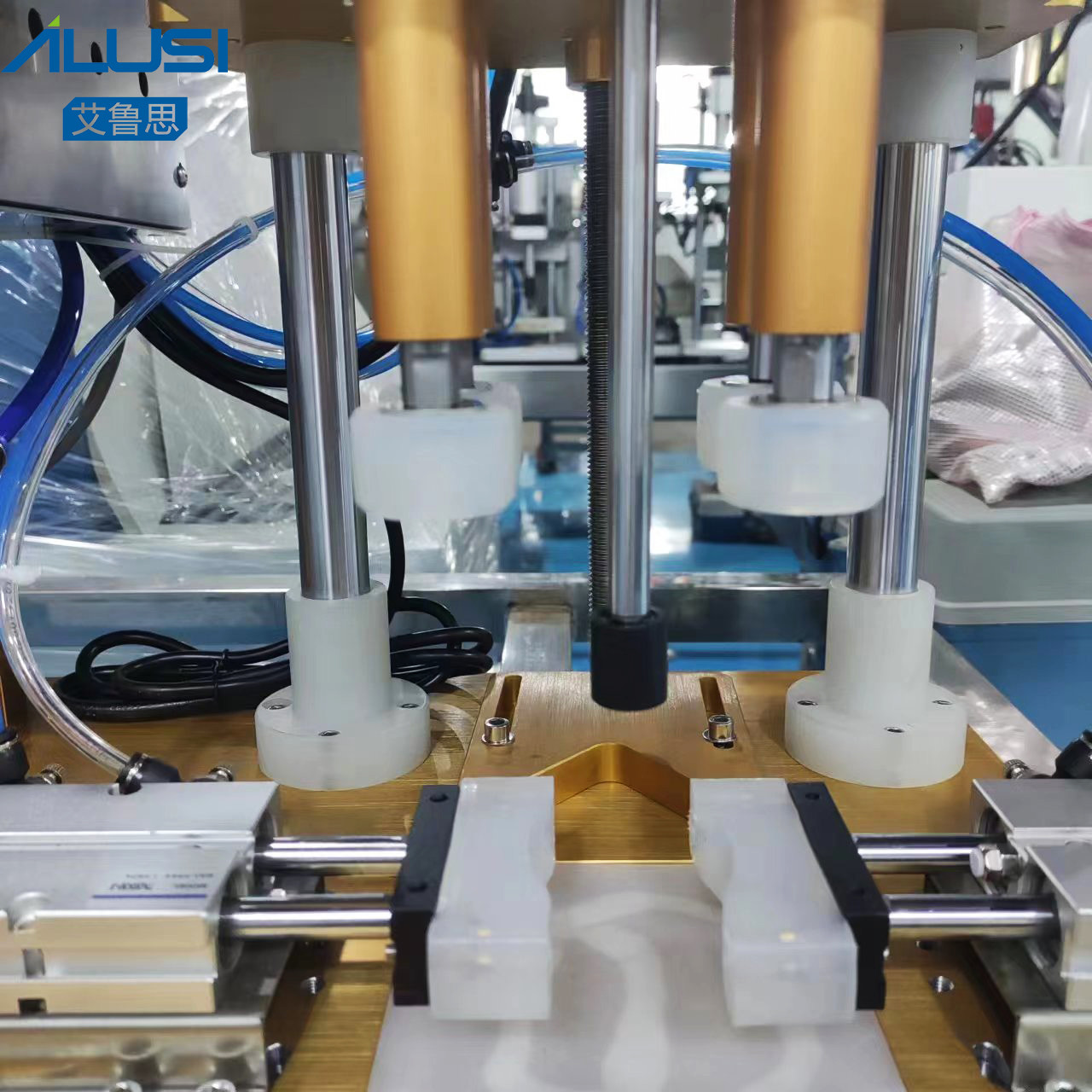

The capping process involves placing a container under the capping

head and activating the machine. The machine will then apply the

cap to the container using one of several capping methods,

including screw capping, press capping, and more.

One of the key features of a multi-function capping machine is its

versatility. The machine can accommodate a range of container sizes

and cap types, making it suitable for a variety of products and

industries. Additionally, the machine can be adjusted to

accommodate different capping methods, providing flexibility and

customization.

The semi-automatic aspect of the machine allows for increased

efficiency and productivity compared to manual capping. However,

some manual intervention is still required, such as placing the

container under the capping head and activating the machine.

The machine is designed to be easy to operate and maintain, with

simple controls and minimal setup required. It is also built with

high-quality materials and components, ensuring durability and

reliability.

Item NO.:APM-XG-SC

Lead Time:10 Days

Product Orgin:China

Shipping Port:Guangzhou Port

Payment:DDT, DDP, EXW, C&F, CIF and etc.

MOQ:1

Product Detail

Main Features:

1) Host electricity box and brace use 304 stainless steel, base

plate and the fuselage formed by oxidation for aluminum alloy;

2) Adopt imported brand motor, double motor, change different

specification of the bottle, only need to adjust the height of the

screw head, simple operation;

3) Adopting digital relay control, lock time, lock cover, and

torsion size can be adjusted; Lock covering rotational speed can be

adjustable, can according to the material of cap to adjust the

screw cap degree of tightness;

4) The machine can be lock different shapes and specifications of

the bottle cap, such as lock duck mouth cap, pointed mouth cap,

rules of irregular plastic cap, rules of the round cap etc,

stability is strong, screw cap standard, lock cover a wide range;

5) This machine special for plastic cap, spray-head, pump head,

spray pump, hand button spray gun,etc that the spiral seal designed

for screw cap difficult problem;

Parameter of Desktop Capping Machine:

| No | Item | Description |

| 1 | Bottle lock range | Bottle height30-300mm bottle width: 15-100mm |

| 2 | Lock lid wresting | Standard Value 4~8kg/cm |

| 3 | Power | 80W |

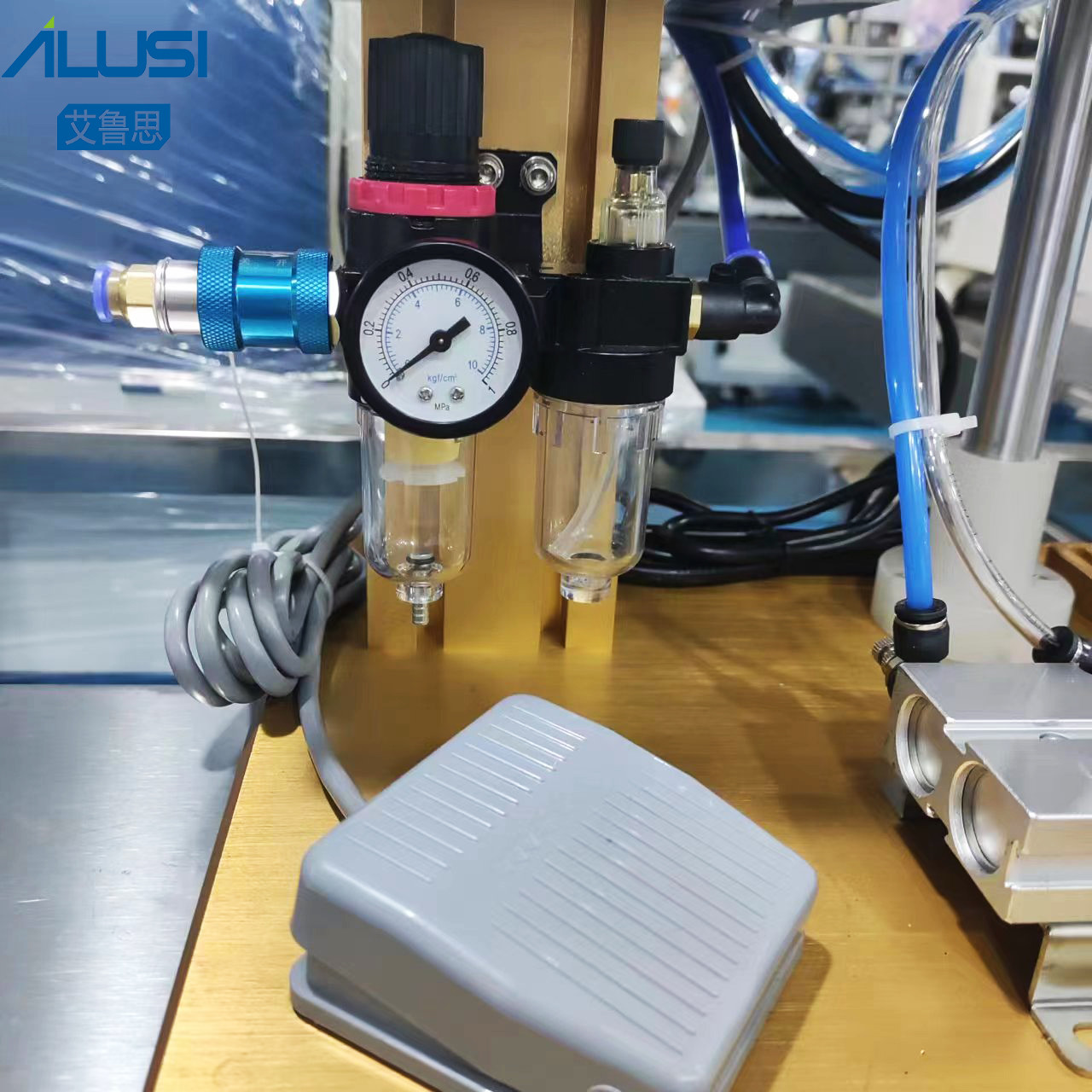

| 4 | Use of gas source | 0.4-0.6MPa |

| 5 | Voltage | 220V/50Hz |

| 6 | Size | 50*38*70cm |

| 7 | Net weight | 35kg |

Scope of application:

1) Capping for plastic lids of various bottles, jars, atomizer, etc.

2) Widely used in cosmetic, drinks, chemical, medical, food industry etc, which can highly improve productivity and product quality

3) For a variety of cosmetic, pharmaceutical, chemical industry, nozzle, pump head, spray pumps, hand gun caps lock button cover machinery.

* Before you place an order, please confirm with the salesman whether this capping machine is suitable for your bottle.

Package & Delivery:

To ensure the quality of our service, we will follow the standard package upon delivery:

1. All products before delivery should be tested by assembly and commissioning engineers. Our salesman need to send the tested video to the customer to ensure working well of the machines. Precision parts need to be packed in film or carton.

2. All products are packed in wooden boxes. Firmly fix the edge of the foot of the equipment to adapt the machine to the requirements of loading and uploading.

Factory:

Our Service

After-sales Service: Online support,Video technical support,Free spare parts

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2: How does your factory do regarding quality control?

A2: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3: What’s the guarantee and the after service if we purchase from you?

A3: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4: Are your machines difficult to operate? How do you teach us to use the machine?

A4: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5: Can you make the machine according to customers' request?

A5: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.