Shenzhen Adkiosk Technology Co., Ltd. |

|

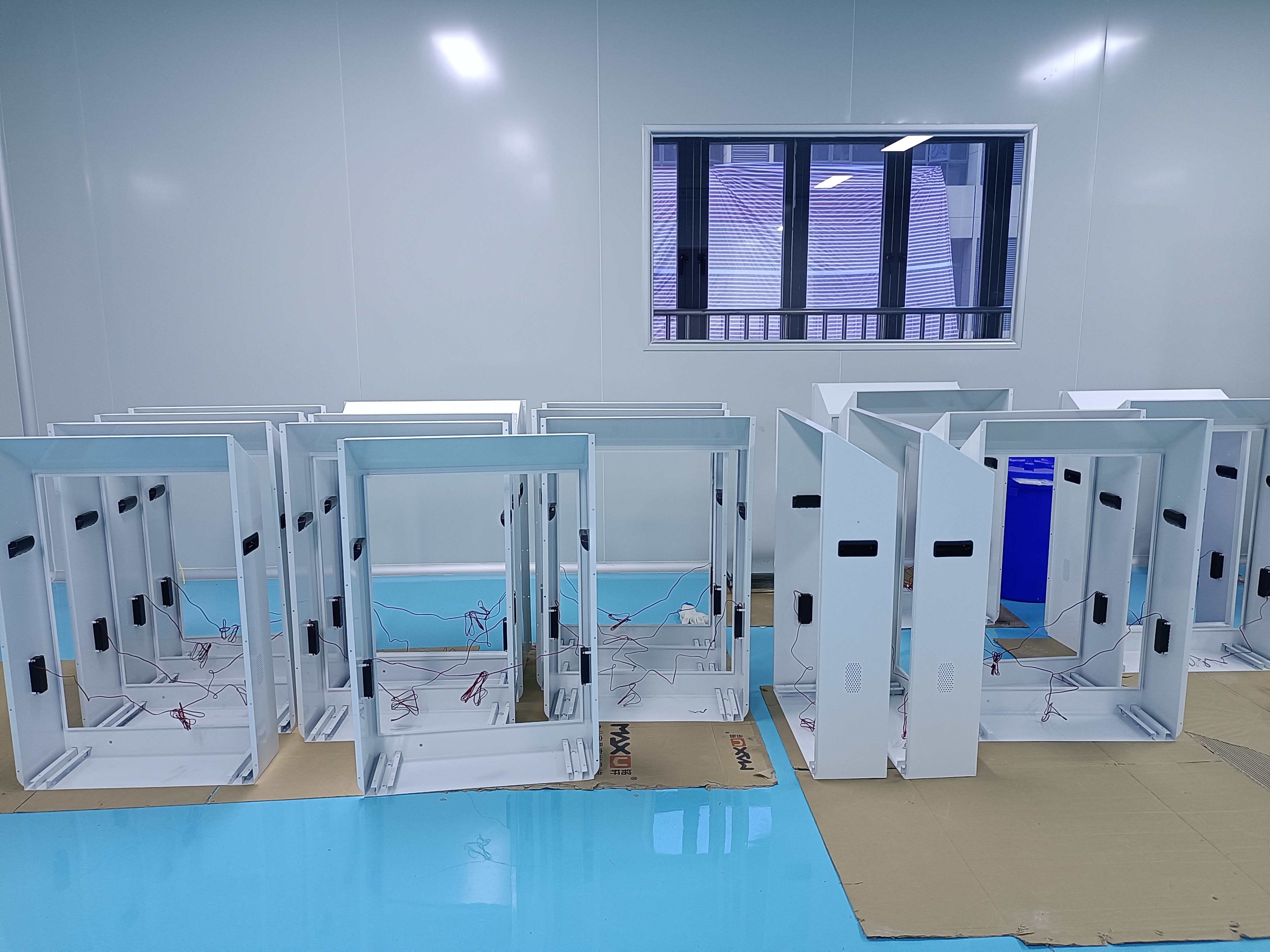

ODM OEM Sheet Metal Frame Fabrication Metal Stamping Parts Ladder Pressed Component

| Material | Steel, Stainless steel, Aluminium, Brass, etc. | |||||||||

| Specification | As your drawing | |||||||||

| Processing | Laser cutting, bending, punching, welding, stamping, riveting, etc. | |||||||||

| Surface treatment | Polishing, galvanizing, powder coating, anodizing, electroplating, brushing, silk screen, etc. | |||||||||

| Drawing format | CAD, solidworks, PDF, pictures | |||||||||

| Service Type | OEM&ODM | |||||||||

Quality assurance methods for sheet metal processing

1. Sheet metal processing needs to understand customer

requirements. When touching new types or new orders, you must have

a certain understanding of the customer's products, and understand

the customer's requirements for the appearance and size of the

product, and the main purpose of the product .

2. The design department obtains the drawings to make the process

drawings, and sends them to the production workshop after the

inspection. The first sample of CNC machine tool blanking must be

fully inspected, (CNC machine punching, fiber laser cutting, etc.)

the blanked product workpieces are inspected, including size,

conduct, etc., during mass production, all the first samples must

be tested before they can be mass-produced. Production.

3. For the welded or bent finished products, carry out sampling

inspection on the size according to the requirements of the

drawings. During the sampling inspection, each size must be

determined. In addition, the appearance must be fully inspected. If

it does not pass, it must be adjusted immediately and re-inspected.

Carry out a full inspection on the appearance of products with

metal surface treatment.

4. Sheet metal processing includes traditional cutting and

blanking, blanking processing, bending and pressing forming methods

and technical parameters, as well as various cold stamping die

structures and technical parameters. Nowadays, it is the operation

principle and operation method of various equipment. It also

contains new stamping skills and new skills.