Surplus Industrial Technology Limited |

|

Verified Suppliers

|

|

High Frequency switching Power supply electroplating rectifier 0-5000v 0-3000a adjustable

The power supply specification and the outward appearance size can be made according to customer’s requirement.

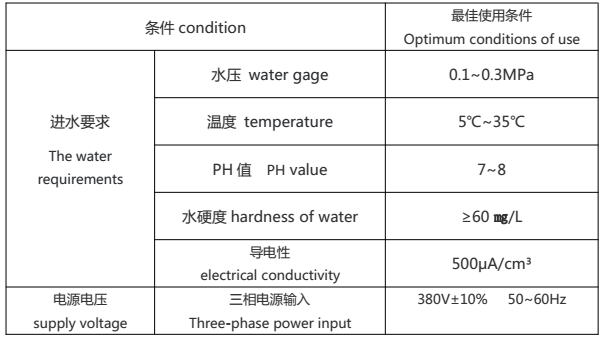

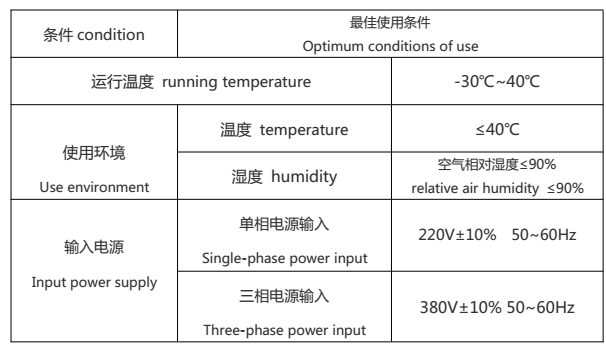

Optimum operating conditions of High Frequency switching Power supply

1. Elevation not exceeding 3000m.

2. The environment is within the range of minus 10 ℃ to 400C;

Anti-freezing measures should be taken in

areas below 00C.

3. The average relative humidity of the area used should not exceed

90%.

4. There is no conductive dust around the environment, flammable

and explosive gas and corrosive

substances that can seriously damage metal and insulation.

5. can be customized according to user requirements of various IP

protection level power supply.

Optimum operating conditions of Water cooling Type of High Frequency switching Power supply

optimum operating conditions for air-cooled type of high-frequency switching power supply

The work shows: LED (green)

Overheat fault display: LED (red) and alarm at the same time

Working limit: can be operated at full load.

ntrol mode: equipped with remote multifunctional high precision

control meter box (cable 6m) optional 485

communication, timing alarm, ammeter, soft start, etc.

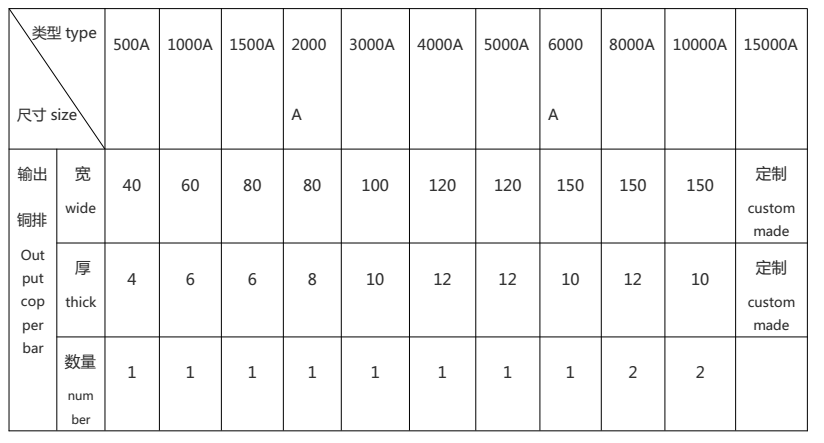

Appearance size of each output copper row in high frequency switching power supply (unit mm)

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and mark your purchase quantity of the product you need.It is much better if you could offer the usage information about products.

We will comfirm the most suitable material and quote our best price to you in 24 hours.

2. Can you accept OEM & ODM?

Yes,we can produce the products according to your demand and drawing.

3. What is your production lead-time for order?

Generally it takes 15-25 days for production.

4. What are your payment terms?

In generally,we quote EXW price+shipping cost,payment 50% deposit by T/T in advance,50% balance paid before shipment.

If the account is small ,so you can pay via Western Union.

Products Show

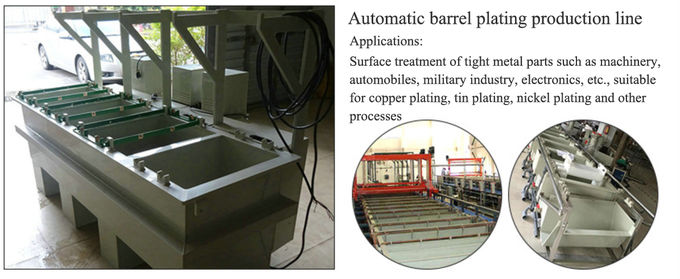

1. Automatic Barrel plating production line

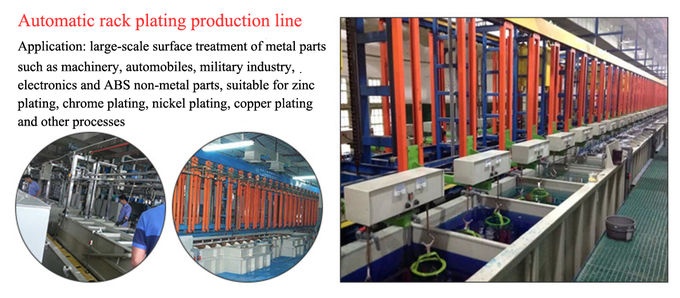

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

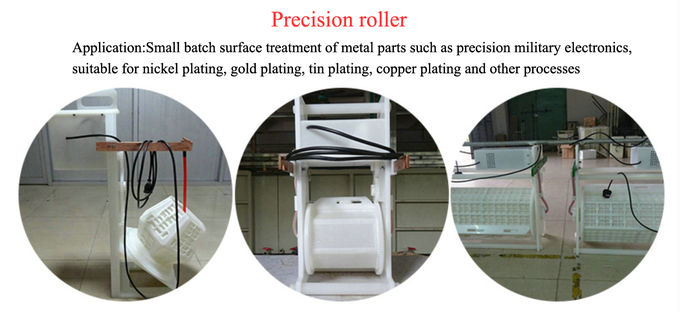

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

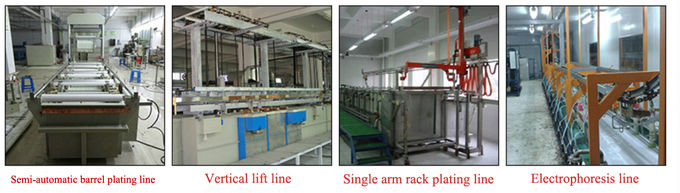

Project display

|

|

|

|

Packing & Shipping

In our company,various packing methods are adopted according to different product features,such as carton boxes,wooden case etc.For electroplating plant equipment ,we can discuss it together and choose the most suitable one.

As for shipment,different ways have their own advantage and disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, much more expensive

By Express: more flexiable, door to door, a little bit expensive