Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

36V 1000A anodizing rectifier

The application range of the anodizing rectifier includes aluminum profile anodizing, aluminum products anodizing coloring, hard anodizing, etc. The anodizing power supply current range is 1A~30000A, and the Anodzing power supply voltage range is 1 V~2000V.

Specification

| SPECIFICATIONS FOR GKD36-1000CVC | |||

| Input AC | 380V±10% | 3 phase | 50/60Hz |

| Output DC | Volt | 0~36V Adjustable | |

| Current | 0~1000A Adjustable | ||

| Power | 36KW | ||

| Efficiency | >85% | ||

| output Frequency | 40KHz fixed | ||

| output ripple | 5% | ||

| Protection | Short circuit protection Overheating protection Phase lack protection Input over/low voltage protection | ||

| Working Condition (Temperature) | -10℃~50℃ | Control mode | Panel control Remote control |

| Net weight | 250kg | Working mode | Constant Voltage(CV) Constant Current(CC) |

| Dimension(mm) | 790*910*1080mm | Cooling way | air cooling |

36V 1000A anodizing rectifier features

36V 1000A anodizing rectifier rectifier picture:

THE DIFFERENCE BETWEEN SCR & IGBT SWITCH RECTIFIER

1, efficiency

SCR: 70%

IGBT:90%

2,Transformer

SCR:Power frequency transformer, large volume about 200kg

IGBT:without Power frequency transformer

3,Energy saving efficiency

SCR: bad

IGBT: energy saving about 15%-30%

4, start/stop with load

SCR: can’t

IGBT: can

5,control circuit

SCR:Complex, request synchronous and difficult to integrate

IGBT:use the simple integrated circuit board, and anti-corrosion treatment completely closed.

6,constant current accuracy

SCR:<5%

IGBT:<1%

7,cooling way

SCR: water/oil/air cooling

IGBT:water/air cooling

8,work frequency

SCR:50HZ

IGBT:20KHZ

9,control way

SCR:Phase shift trigger

IGBT: PWM

10,output DC

SCR:half wave

IGBT:High density DC square wave

11,Disturbance to power grid

SCR: large,Not easy to eliminate

IGBT: small,easy to eliminate

12,size and weight

SCR: large size and heavy

IGBT: small and light weight

13,Allowable fluctuation range of input voltage

SCR: ±10%

IGBT:±15%

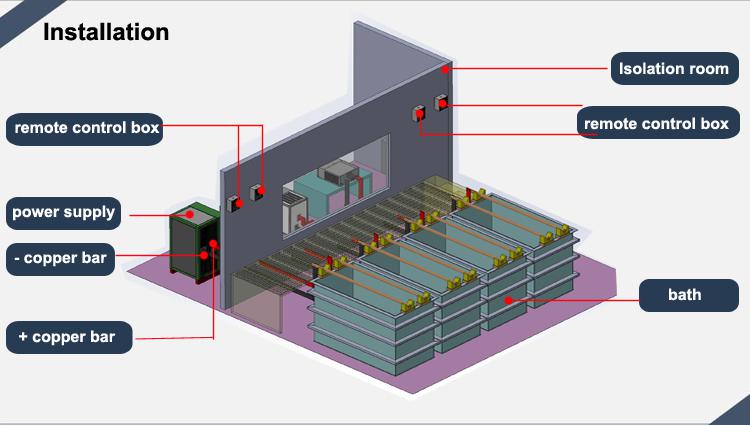

36V 1000A anodizing rectifier Installation

| 1, Placing rectifier and keep the body stability; ensure good ventilation. |

| 2, Checking anodizing rectifier out cover if loosing. |

| 3, Connecting shell to ground to prevent static electricity. |

| 4, Conecting the AC input wire |

| 5, Connecting the DC output copper bars |

| 6, Connecting the rectifier remote control box,if local control ,skip this step |

| 7, Turn on air switch, then the fan starts to rotate and the power indicator light. |

| 8, Clockwise rotation adjustment button, voltmeter degree increases, working indicate light lighting. |

| 9, Adjust knob to maximum, then the voltmeter should indicate the rated voltage, current meter indicates the load volume accordingly. |

| 10, Disconnect the air switch, turn off the rectifier |