Henan Dongtai Gear Wheel Co., Ltd. |

|

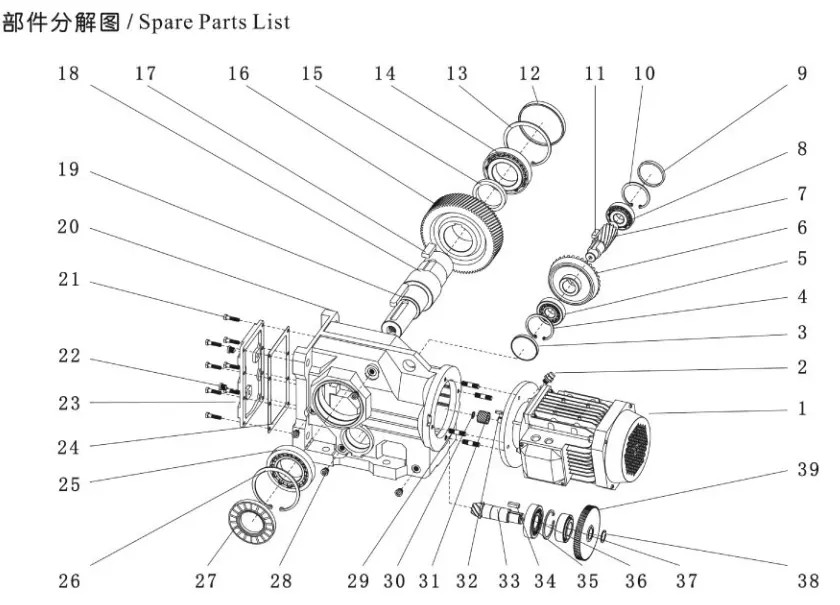

Products Description

1. Highly Standard Modular Designed: The products are easily

connected with and driven by different types of motors and various

input power. The same type geared motor can be adapted to optioned

powers of motors. It is therefore easy to realize different

solution for varied requirements.

2. Ratio: Featured many closely divided ratios and wide range of

them. Very big final ratios can be obtained through combined unites

to reach extremely low output speeds.

3. Mounting Arrangement: No strict limitation to the mounting

arrangement.

4. High Strength, Compact Dimension: Housings are made of high

strength cast iron. Gears and shaft gears are finished with gas

carburizing process and precise grounding to sequentially get high

loading capacity of per certain volume.

5. Long Service Life: Under the condition of accurately selecting

type size and the normal maintenance and use, main components

(expect those easily-disabled parts) can last as long as up to more

than 25,000 hours. Easily-disabled parts include lubricating oil,

oil seals, and bearings.

6. Low Noise: All key components are finished by precisely

machining, accurate assembly, and finally tested, and therefore,

fairly low noise is reached.

7. High Efficiency: The efficiency of gear unit can reach 95%, The

efficiency of worm gear unit can reach 89%.

8. Large radial loading ability.

9. Axial load ability of up to 5% of radial load.

Technical Data:

Product Application

K series reducer is a kind of gear is used to reduce the motor speed and improve the output torque of the principle of speed reducer. It uses the gear and gear meshing, with advanced design and novel structure of retarding mechanism.

• Food processing machine

• Construction machinery

• Wood processing machine

• Conveyors

• Agriculture machine

• Crane/ mineral machinery

Product Feature

Our K series helical gear reducers are based on the building block design, so its convenient to fit all types of motors or to connect with other power input, and its possiblefor different types of machines to combine or connect.

• High modular design.

• Efficiency and save power.

• Save cost and low maintenance.

• Excellent sealing, wide range of industry application.

• High loading support, stable transmitting and low noise level.

Product process

Box processing process

Mechanical modeling of metal mold → casting on production line →

artificial aging treatment → shot peening → machining center

processing → three-coordinate detector detection

Gear processing process

Forging → normalizing > roughing → finishing car → hobbing → tooth end chamfering → carburizing and quenching (HRC58-62) → shot blasting → grinding end face and inner hole → grinding tooth → accuracy detection (tooth shape, tooth direction, tooth Distance, level 6) → wire cutting keyway > magnetic particle inspection → ultrasonic cleaning and rust prevention

Tooth shaft machining process

Forging a normal fire and a rough car (including the center hole) a finishing car → hobbing → milling key slot → carburizing quenching (HRC58-62) a shot blasting a grinding center hole → grinding outer circle → grinding tooth → detection (tooth Shape, tooth direction, pitch, etc., level 6) → magnetic particle inspection → ultrasonic cleaning and rust prevention