Active Member

|

[China]

Address: CRANE INDUSTRAL PAPK CHANGYUAN

Contact name:Alisa

HENAN KONE CRANES CO.,LTD |

China Factory Supply Ultrasonic Vibration Transducer Graphite Screening Equipment 300W Vibrating Ultrasound Transducer

Ultrasound Screen Transducer

Piezoelectric transducer uses the piezoelectric effect to realize transduction between electric and sound energy. It comprises a radiation head, electrode, cap, prestressed bolt, piezoelectric chip and an insulating tube. The piezoelectric transducer is widely used in ultrasonic cleaning machine and high-power industry cleaning devices

Transduer parameter:

Frequency: 33KHZ

Resonance Impedance: 20-40

Static Capacity: 5000

Input Power: 100W

Generator parameter:

Frequency: 33KHZ

Input power: 300W

Above transducer and generator can drive and vibrate one

100cm-120cm screen.

Payment term: T/T, Western Union, Paypal, bank account

Production Lead Time: Normally according to your order quantity,

5~7 DAYS AFTER PAYMENT.

Shipping Methods: Express(FEDEX, DHL, TNT etc), Air shipping, Sea

shipping

1. Introduction:

The GTS30 ultrasonic sieving system is a simple, practical and reliable screening system that is the most effective solution for current mesh clogging. It can be widely used in pharmaceutical, metallurgical, chemical, mineral processing, food and other requirements industry, with high precision screening and filtration, the mesh is not blocked and so on, really solve the reunion, static, strong adsorption card network Holes and other screening problems. This is a major technological breakthrough in the domestic sieving industry.

2. Structure:

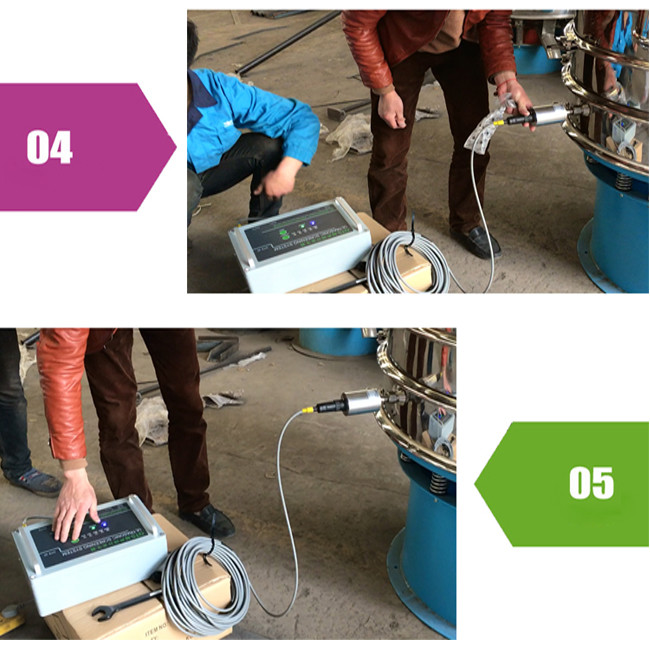

2.1 Ultrasonic control device: 30KHz high frequency ultrasonic generator. Built-in microcomputer chip, according to the different state of ultrasound for full digital frequency automatic tracking, without manual adjustment, simple and convenient operation.

2.2 High frequency cable: Between the ultrasonic oscillator and the ultrasonic controller adopt cable connection.

2.3 Connector: Air connector.

2.4 Converters: High Frequency Ultrasonic Transducers.

2.5 Ultrasonic grid: composed of external grid and resonance ring.

2.6 Screen: for 10 mesh to 635 mesh.