SHEAN (CANGZHOU) CORP LTD |

|

Refinery Pipe Bends Fully Automatic Hot Induction Making Machine

Suitable environment for Refinery Pipe Bends Fully Automatic Hot Induction Making Machine:

Temperature -5-45℃,reversely humidity≤80%, input voltage is three

phase four line 380V( -10% — +15%),Frequency 50Hz±2%,working time

8-24 hours/day, No corrosive media, enough running space without

wind and rain.

| Max size | Model | Heating power | Cylinder capacity | Thickness |

| 6” | HYG-159 | 200KW | IDΦ140 ODΦ168 | 5-20 |

| 8” | HYG-219 | 200KW | IDΦ140 ODΦ168 | 5-20 |

| 12” | HYG-325 | 250KW | IDΦ180 ODΦ219 | 5-20 |

| 16” | HYG-426 | 350KW | IDΦ180 ODΦ219 | 5-20 |

| 20” | HYG-530 | 400KW | IDΦ180 ODΦ219 | 5-20 |

| 24” | HYG-630 | 500KW | IDΦ200 ODΦ245 | 5-20 |

| 28” | HYG-720 | 600KW | IDΦ200 ODΦ245 | 5-20 |

| 32” | HYG-813 | 800KW | IDΦ220 ODΦ273 | 5-20 |

| 36” | HYG-914 | 800KW | IDΦ250 ODΦ299 | 5-20 |

| 48” | HYG-1220 | 1000KW | IDΦ280 ODΦ325 | 5-20 |

| 56” | HYG-1420 | 1000KW | IDΦ280 ODΦ325 | 5-20 |

| 60” | HYG-1520 | 1000KW | IDΦ280 ODΦ325 | 5-20 |

| 64” | HYG-1620 | 1000KW | IDΦ320 ODΦ377 | 5-20 |

Our Refinery Pipe Bends Fully Automatic Hot Induction Making Machine:

1. Main body is strength and durable.

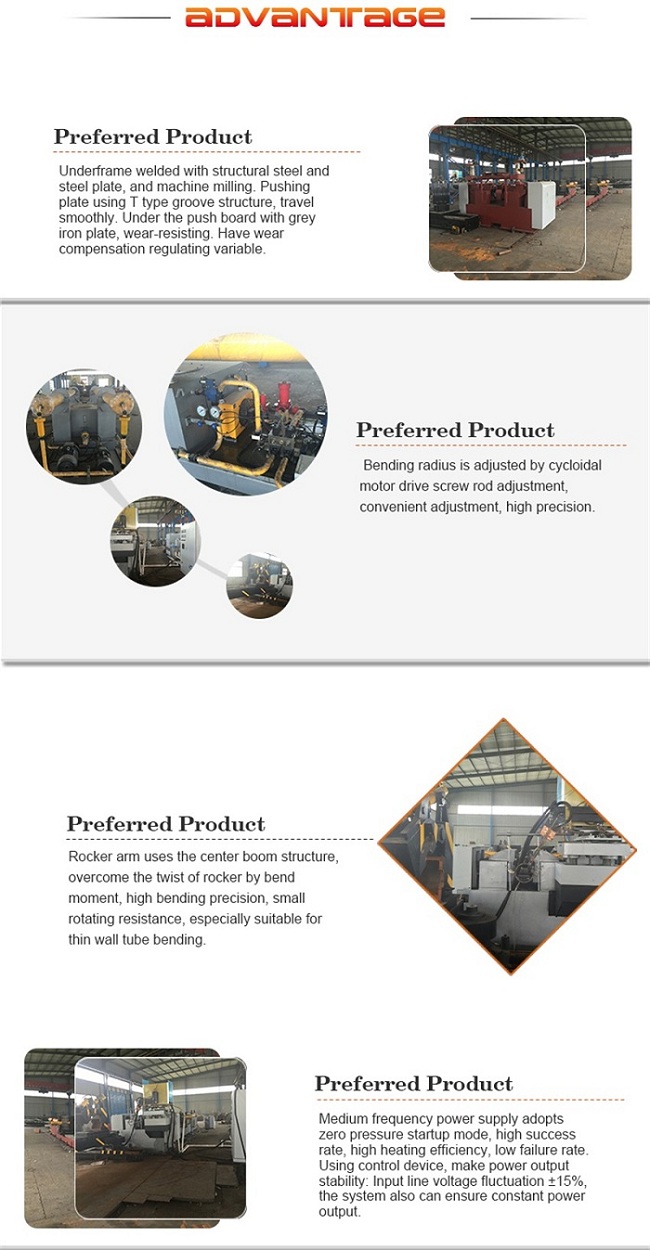

2. Underframe welded with structural steel and steel plate, and

machine milling. Pushing plate using T type groove structure,

travel smoothly. Under the push board with grey iron plate,

wear-resisting. Have wear compensation regulating variable.

3. Bending radius is adjusted by cycloidal motor drive screw rod

adjustment, convenient adjustment, high precision.

4. Hydraulic system uses frequency control, working speed stepless

variable speed, convenient adjustment, improve the production

efficiency, saving energy save electricity. According to the

feeding speed control motor speed, adjust the fuel delivery

accordingly, on-demand oil supply, hydraulic oil without high

pressure unloading, the oil temperature not too high.

5. Rocker arm uses the center boom structure, overcome the twist of

rocker by bend moment, high bending precision, small rotating

resistance, especially suitable for thin wall tube bending.

6. Medium frequency power supply adopts zero pressure startup mode,

high success rate, high heating efficiency, low failure rate. Using

control device, make power output stability: Input line voltage

fluctuation ±15%, the system also can ensure constant power output.