SHEAN (CANGZHOU) CORP LTD |

|

Hot Induction Pipe Bending Machine Use Medium Frequency Power Source

Production Description / Brief Introduction of Hot Induction Pipe Bending Machine Use Medium Frequency Power Source:

1) Turn on and turn off easily,and power failure.

2) Adopt constant power to control the circuit, maintain constant power while malting, and keep faster melting rate.

3) Set up over voltage, over current and water deficient protector, and run safely.

4) The motherboard adopts CAD technology, integrated circuit board, low-fault-rate, easy-manipulating,effortless maintenance.

5) Zero voltage starts up softly, high initial over, no impact for the electric network.

6) Apply to melting ferrous metal and non-ferrous metal like copper, aluminum, brass, steel,iron,stainless steel etc...

The Specification of our Hot Induction Pipe Bending Machine Use Medium Frequency Power Source:

| Power | Input Power | Output Power | Cool Water | Cooling | Out-Dimension | Weight |

| Model | (V) | (KW) | (T/h) | Water Pressure | (mm)(L×W×H) | (KG) |

| (Mpa) | ||||||

| KGPS60 | 380 | 60 | 2.5 | 0.25 | A750×800×1980 | 400 |

| KGPS100 | 380 | 100 | 3 | 0.25 | A750×800×1980 | 480 |

| KGPS160 | 380 | 160 | 5 | 0.3 | B750×800×1980 | 600 |

| KGPS250 | 380 | 250 | 5 | 0.3 | B-1400×800×1980 | 700 |

| KGPS400 | 380 | 400 | 6 | 0.4 | C-1800×800×1980 | 850 |

| KGPS500 | 380 | 500 | 6 | 0.4 | C-1800×800×1980 | 1000 |

| KGPS750 | 380 | 750 | 8 | 0.4 | C-1800×800×1980 | 1250 |

| KGPS1000 | 380 | 1000 | 10 | 0.4 | D-2200×800×2100 | 1250 |

| KGPS1500 | 380 | 1500 | 12 | 0.4 | E-3600×800×2100 | 1750 |

| KGPS2000 | 380 | 2000 | 18 | 0.4 | E-3600×800×2100 | 2000 |

| KGPS2500 | 380 | 2500 | 20 | 0.4 | E-3600×800×2100 | 2500 |

| KGPS3200 | 380 | 3200 | 35 | 0.4 | E-3600×800×2100 | 2800 |

| KGPS6500 | 380 | 6500 | 50 | 0.4 | F-5200×800×2100 | 3500 |

| Other customized specifications are welcomed. | ||||||

APPLICATIONS of our Hot Induction Pipe Bending Machine Use Medium Frequency Power

Source:

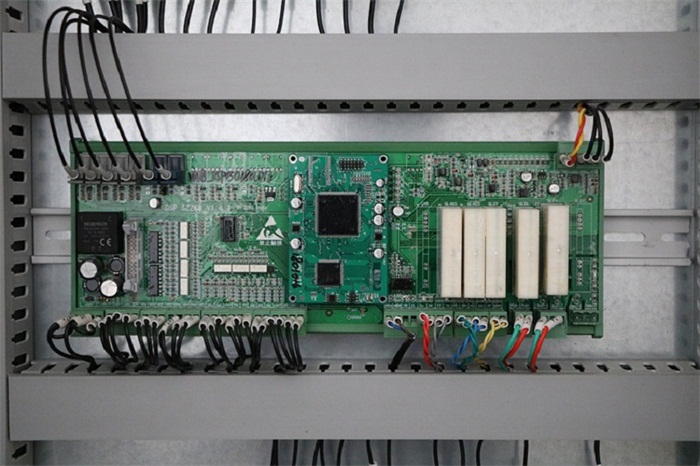

Electric Board

Main control circuit board as the main part of the machine, we made in their research and development, and adopted by the company and built since the automatic welding and testing equipment to ensure that each set of machine can achieve the best effect, and we have main control board in stock lone time, can satisfy the parts supply problems.

Induction coils

The induction coil inside the furnace body is treated with two insulations. The first spray of high temperature insulation paint. The second round of glass fiber tape. The service life of the treated furnace lining and induction coil will increase by more than two times.

NOTE:

Please do not touch any exposeed electric components and induction coils when it is starting work .Please close system if repair or moving . Refuse electrocute!