Zhengzhou MG Industrial Co.,Ltd |

|

Verified Suppliers

|

|

Description of Dry Mortar Batching and Packing Plant:

MG semi automatic dry mortar plant steel platform design in modular structure which has great advantages in transportation and easy installation, saving labor cost can realize fast installation. This dry mortar plant can also called energy-saving dry mortar mixing line, Which can feedvarious materials into the bin, under the automatic control system, it can realize automation in collecting, feeding, filling and packing. It is the ideal selection for set up a dry mortar factory with reasonable price and quick refund.

Advantages of Dry Mortar Batching and Packing Plant:

1. High mixing homogeneity at 99.9%

2. High efficiency at 90~120 seconds per batch

3. No dead corner for mixing. No residual for discharging

4. Adopting advanced world famous brand components with long

service life.

Technical parameters of Dry Mortar Batching and Packing Plant:

| Model | Simple dry mortar plant | Improved simple dry mortar plant | Semi-automatic dry mortar plant | Full automatic dry mortar plant |

| Out put | 1-3t/h | 4-5t/h | 5-8t/h | 10-30t/h |

| Components | screw conveyor, horizontal ribbon mixer, storage tank, packing machine, control cabinet, air compressor | screw conveyor, twin shaft mixer, storage tank, packing machine, control cabinet, air compressor | bucket elevator, twin shaft mixer, holding tank, packing machine, control cabinet, air compressor | cement silo, screw conveyor, automatic weighing system, bucket elevator, premix tank, twin shaft mixer, holding tank, packing machine, automatic control cabinet, air compressor |

| Occupied area | 20m² | 20m² | 50-60m² | 60-100m² |

| Total power | 5.5-7.5kw | 6-11kw | 24-28kw | 60-120kw |

Mixer Volume

| 3300*1050*2100(mm) | 2m³ | 2m³ | 2m³, 3m³, 4m³ |

| Equipment height | 3-4m | 3-4m | 6-8m | 8-13m |

| Man power | 2-3person | 2-3person | 3-4person | 3-4person |

| Batching and packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Automatic batching & Automatic packaging |

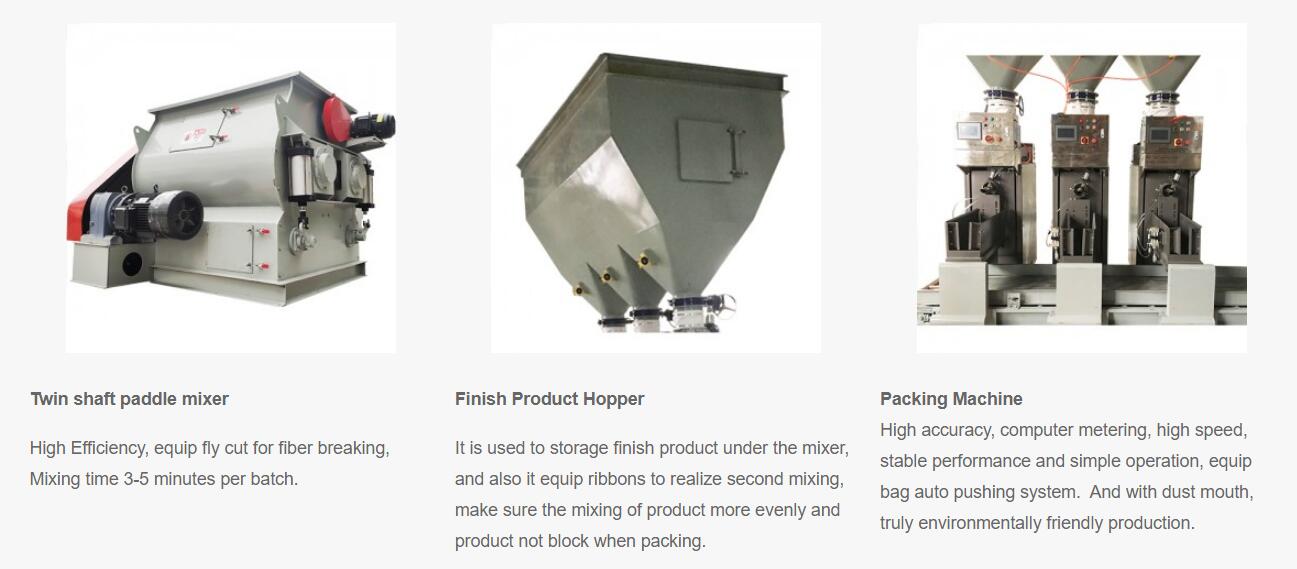

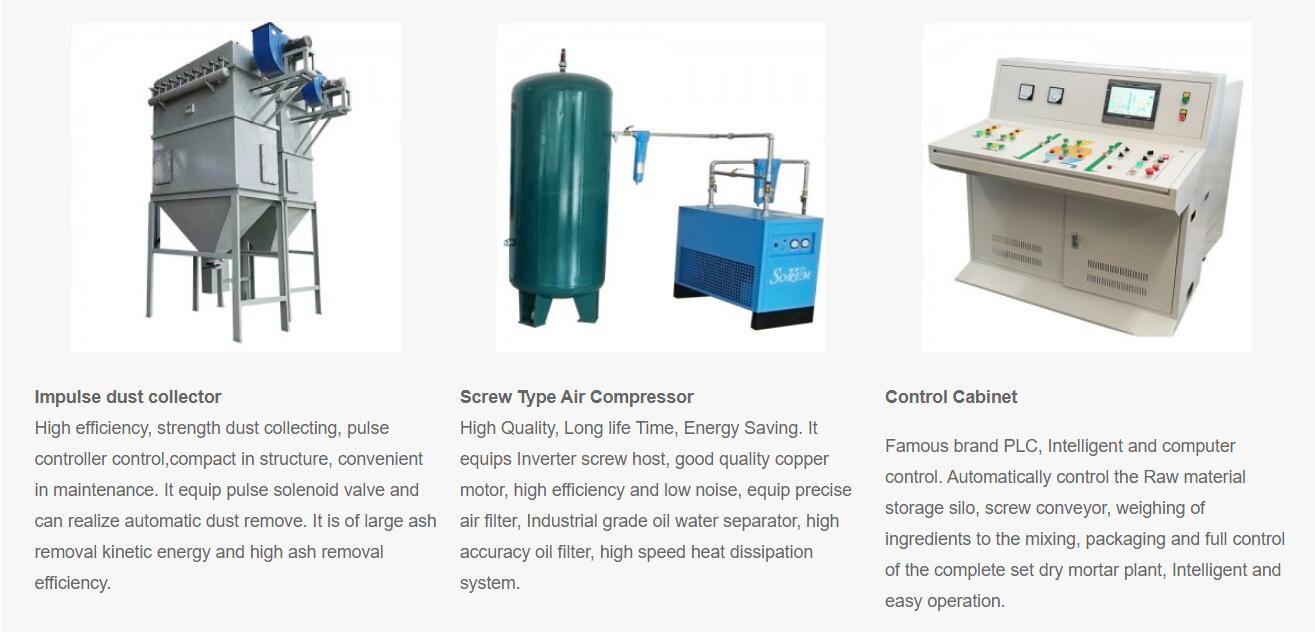

Main configuration of Dry Mortar Batching and Packing Plant:

Dry sand production part: In order to obtain dry sand that meets the production requirements, the raw wet sand must be dried and the moisture content should be less than 0.5%. The main production equipment used in the drying process is a three-pass dryer, which is newly developed for the drying of sand Dryer, high thermal efficiency, novel structure, compact, stable and efficient. After the sand is dried, it is sent to a classification screen by a belt conveyor. The dry sand is divided into several grains according to the process requirements and stored in the discharge bin.

Machine delivery of Dry Mortar Batching and Packing Plant:

Why choose us?

» The structure we designed is advanced and compact. According to your site and capacity, we can provide you reasonable design with factory price.

» Cooperated with Germany Wacker Company, then we supply advanced construction materials formula and top rank additives together to ensure the end products good quality you produce.

» Our professional installation team has rich experience to complete the installation, commissioning fast, and also to train workers how to operate, maintain the equipment.

» As a professional and highly experienced manufacturer of dry mortar mixing equipment in China for more than 20 years. We are in the leading position in this scopes.

Customer visiting of MG Dry Mortar Mixer Machine:

Our Service:

1.According to your inquiry, We will reply to you in 24 hours.

2.Best After-sales: We will send the technical personnel to the site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and man-made factors, the damage caused by design, process and manufacturing equipment, the seller is responsible for sending people to offer free repair.

4.We will send the spare parts as soon as possible when necessary, equipment repair parts provided by the seller are original, authentic, quality goods.

We are professional manufacture supplier dry mortar powder mixing equipment plant and sand dryer plant in China, supporting one-stop service for your plant. Details including working site design, foundation drawing, installation and debugging, worker training, formulations, chemicals, after-sale service and technical supports.