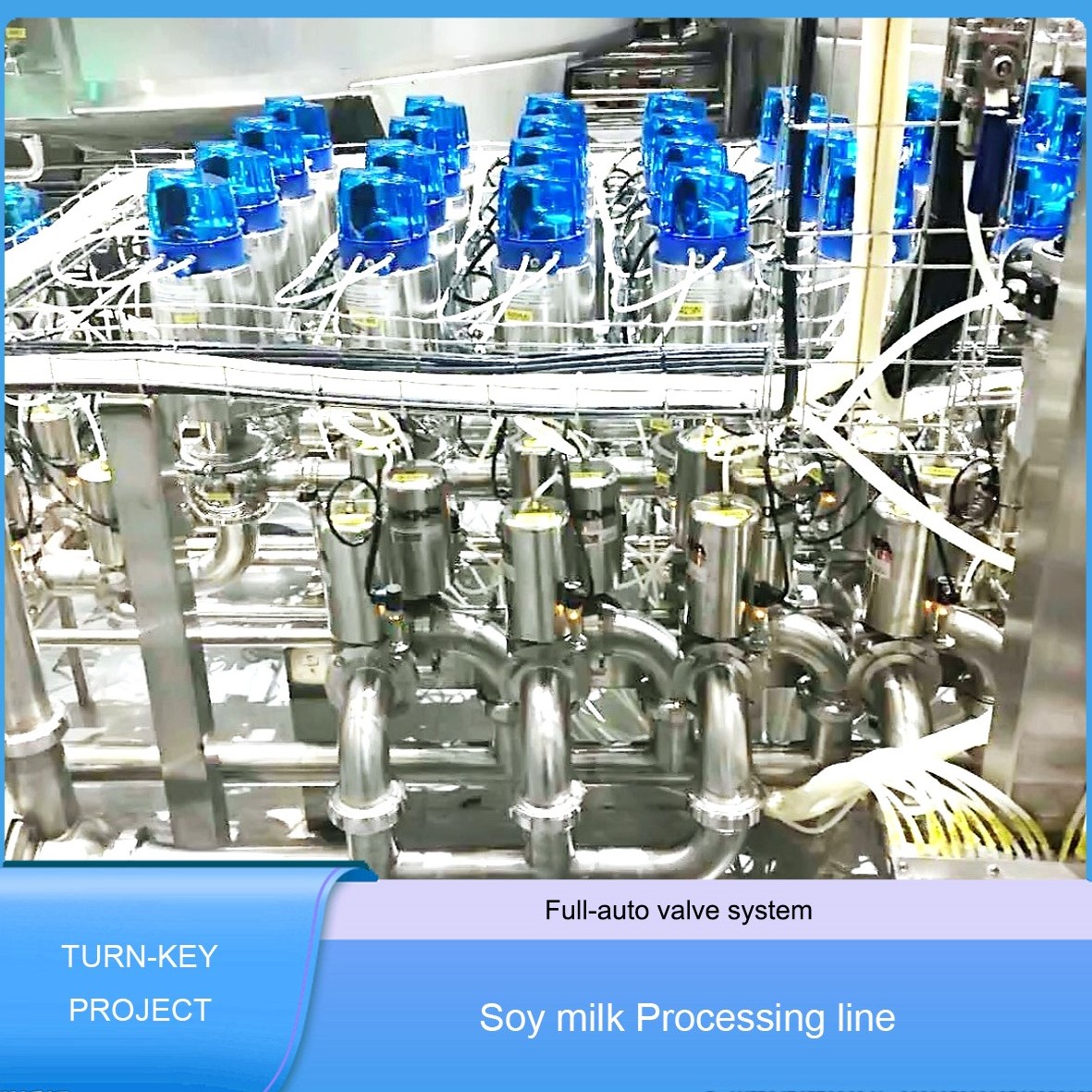

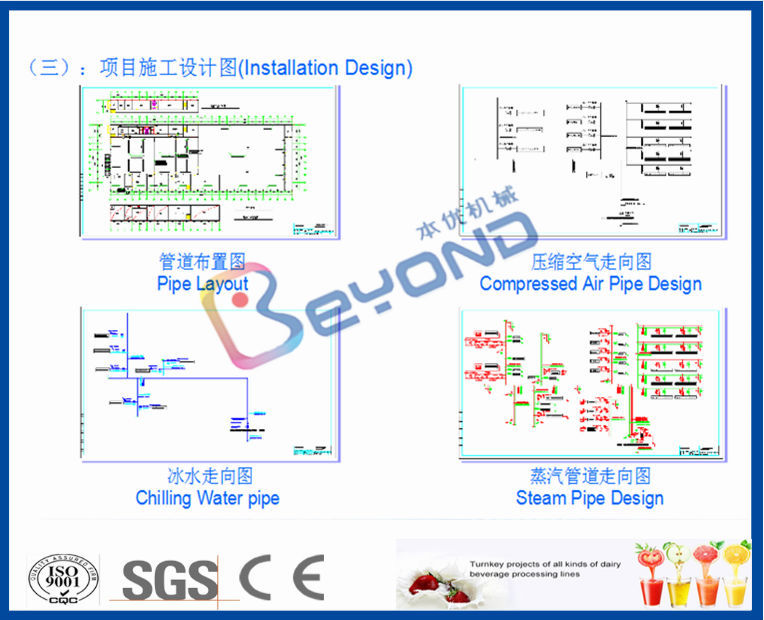

Shanghai Beyond Machinery Co., Ltd |

|

Raw material: grains,including corn, rice, soybean, almond, peanut, oats, walnut, grain, etc.

finished products:grains milk /drink, corn juice, rice milk, soy milk/soybean milk, almond milk, peanut milk, etc.

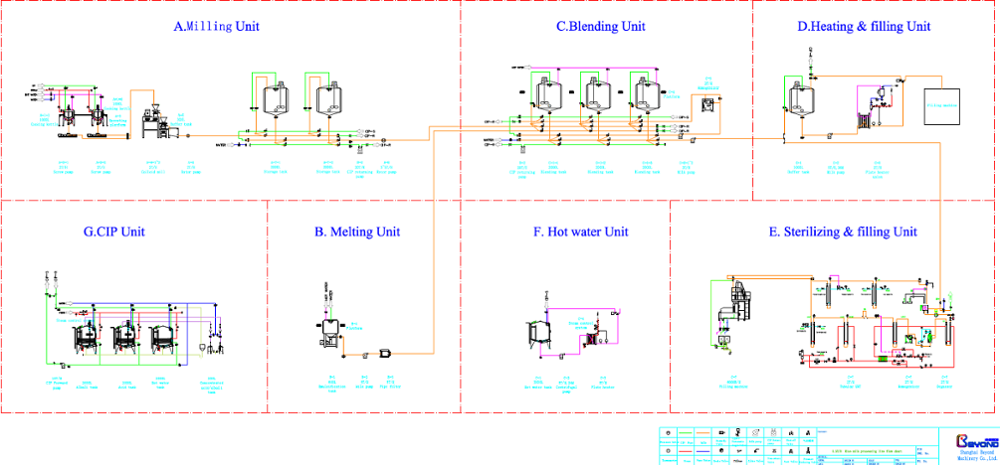

Main processing:

(aseptic package method) washing---->soaking/cooking ----> milling/grinding----> filtering----> mixing ----> homogenizing----> aseptic UHT sterilizing----> aseptic filling----cooling and drying----labeling----> carton apcking

End product package of this grain milk (grains milk /drink, corn juice, rice milk, soy milk/soybean milk, almond milk, peanut milk) processing line can be plastic pouches, plastic cups, plastic bottles, glass bottles, roof top box etc. For this dairy production line according to different end product and package type, the production technology is differently designed but commonly include the following steps.

Usage:

Applicable for large milk collection center, or for milk outdoor

storage at large milk production plant; also used at other food and

pharmacy factory for storage of liquid product.This equipment is

equipped with cleaning system, agitator, sight and view devices,

also have attachments of thermometer and level indication meter.

Usage:

This machine stands between the pasteurizer and the UHT, can be

used for PET hot filling or roof shape filling sterilize.

Full automatic control: UK Spirax Sarco steam pressure reduce

valve, German Burkert or Spirax Sarco temperature control system,

German Labom temperature transducer, Anthone temperature recorder

without paper, South hot water pump, Siemens PLC full automatic

control with touch screen, the precision of temperature control is

±0.5 degree.

Semiautomatic control: UK Spirax Sarco steam pressure reduce valve,

German Burkert or Spirax Sarco temperature control system, German

Labom temperature transducer, Anthone temperature recorder without

paper, South hot water pump, Siemens LOGO control, the precision of

temperature control is ±0.5 degree.

Equipment lis and technical parameter for grain milk (grains milk /drink, corn juice, rice milk, soy milk/soybean milk, almond milk, peanut milk) processing line

| No. | Flow No. | Name | Size | Main technology parameter |

| 1 | A | Milling unit | ||

| 2 | A-0 | Rice or oats washing machine | Q=500Kg/h | SUS304 |

| 3 | A-1 | Cooking kettle | 1000L | SUS304 stainless steel, three layer miller jacket, half open type, central frame blender, bottom flange outlet, with built-in scale |

| 4 | Temperature control system | UK Sprirax sarco steam reduce system,Burket angle valve, JUMO temperature sensor | ||

| 5 | A-2 | Screw pump | Q=2T/h | made of sus304 stainless steel, pump lift is 60m |

| 6 | A-3 | Operating platform | made of sus304 stainless steel, size:4000*1000*1500mm | |

| 7 | A-4 | Colloid mill | Q=2T/h | made of sus304 stainless steel,JMS-180 |

| 8 | A-5 | Buffer tank | 300L | made of sus304 stainless steel, |

| 9 | A-6 | Rotor pump | Q=2T/h | made of sus304 stainless steel, pump lift is 60m |

| 10 | A-7 | Temporary storage tank | 2000L | SUS304,double layers, PU insulation, vertical agitator, airtight manhole,ladder,digital readout thermometer,CIP cleaning ball, glass tube level indicator |

| 11 | A-8 | Rotor pump | Q=3~5T/h | made of sus304 stainless steel, pump lift is 60m |

| 12 | Subtotal A: | |||

| 13 | B | Melting unit | ||

| 14 | B-1 | High speed emulsification tank | V=600L | made of sus316L stainless steel, with insulation, with high speed shearing mixer mounted from bottom, speed is 1400rpm, with digital show thermometer, with level scale inside wall |

| 15 | B-2 | Centrifugal pump | Q=5T/h | made of sus316L stainless steel, pump head is 24m, ABB motor |

| 16 | B-3 | Twin pipe filter | Q=5T/h | SUS316, mesh size 100M |

| 17 | B-4 | Platform | SUS304,size:1200*1000*1200 | |

| 18 | Subtotal B: | |||

| 19 | C | Blending unit | ||

| 20 | C-1 | blending tank | V=2000L | made of sus316L stainless steel, with insulation, vertical agitator 43rpm, with attachments sucha as manhole, ladder and digital show thermometer, CIP cleaning head, product enter from side, glass tube level indicator |

| 21 | C-2 | centrifugal pump | Q=3T/h | made of sus316L stainless steel, pump head is 24m, ABB motor |

| 22 | C-4 | high pressure homogenizer | 1.5T/h | SUS316L, 25Mpa, (starting box included) |

| 23 | C-5 | blending platform | SUS304,6000*800*1500 | |

| 24 | Subtotal C: | |||

| 25 | D | Heating unit | ||

| 26 | D-1 | Temporary storage tank | V=1000L | made of sus316L stainless steel, with insulation, vertical agitator 43rpm, with attachments sucha as manhole, ladder and digital show thermometer, CIP cleaning head, product enter from side, glass tube level indicator |

| 27 | D-2 | Centrifugal pump | Q=5T/h | made of sus316L stainless steel, pump head is 36m, ABB motor |

| 28 | D-3 | Plate heat exchanger | 1.5T/H | SUS316L, two section type,T1=20℃, hot water heating, Spirax sarco steam regulating system, stainless steel steam and water mixer, Jumo temperature sensor, include hot water tank and hot water pump, second section is for tower water cooling, can cool product from 80 to 60℃ |

| 29 | Subtotal D | |||

| 30 | E | Sterilizing and Filling unit | ||

| 31 | E-1 | Tubular pasteurizer | 1.5T/H | SUS316L stainless steel, aseptic tye, tubular type, sterilizing parameters:137℃,5S,output temperature 30℃,PLC automatic control |

| 32 | E-2 | Full-automatic vacuum degasser | 1.5T/H | Full-automatic control, SUS316L stainless steel, differential pressure transducer imported from Germany Labom, working vacuum degree -0.64~-0.85Kpa, flow control is frequency converted type, working together with pasteurizer, with condensing device |

| 33 | E-3 | High pressure homogenizer | 1.5T/H | SUS316L, 25MPa, including starting cabinet, frequency conversion control |

| 34 | E-4 | Brick aseptic filling machine | 250ml/B, 6000B/H | |

| 35 | Subtotal E | |||

| 36 | F | Hot water unit | ||

| 37 | F-1 | Hot water tank | V=3000L | made of sus304 stainless steel, insulated with PU,with airtight manhole, cone top and bottom cover, ladder, glass tube level indicator |

| 38 | F-2 | Hot water pump | Q=5T/h | made of sus304 stainless steel, pump head is 24m, ABB motor |

| 39 | F-3 | Plate heater | Q=5T/h | plate heat exchanger is made of sus304 stainless steel, one cooling section, with plastic seal |

| 40 | F-4 | Temperature control system | UK Sprirax sarco steam reduce system | |

| 41 | Subtotal F: | |||

| 42 | G | CIP Unit | ||

| 43 | G | Semi-automatic CIP system | 3×2T | SUS304 stainless steel, double cleaning way, concentrated acid/alkali tank adding system based on US technology, temperature automatic control, 300L×2 acid/alkali concentrate tanks |

| 44 | R | CIP return pump | 20T/H | SUS316L stainless steel, pump lift is 24 meters, mechanical seal |