Shaanxi Aipu Solids Control Co., Ltd |

|

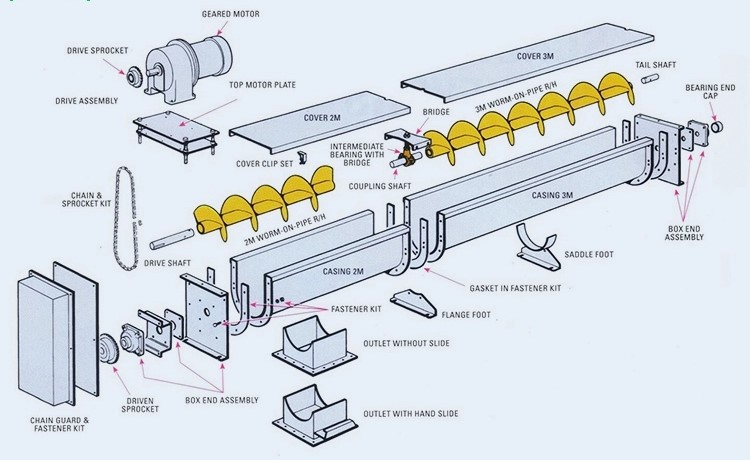

APLS Auger feeder/ Screw conveyor is popular in the oil gas industry for transferring the drilling cuttings to feed to the cuttings dryer, and cuttings collection box. It's a combination of motor and gearbox, the screw blade, and the U shape or circular channel. A U-shaped screw conveyor is a type of screw conveyor. The production is manufactured according to the DIN15261-1986 standard, and the design conforms to the professional standard of JB / T7679-2008 "Screw Conveyor". U-shaped screw conveyor is widely used in food, chemical, building materials, metallurgy, mining, electric power, and other departments, mainly used for conveying small granular, powdery, small lump materials. It is not suitable for conveying materials that are easy to deteriorate, have a high viscosity and easy to agglomerate, and have large water content. The auger feeder is another reference to the screw conveyor. There are fixed speed and VFD ones. For the design, there are horizontal with 0° incline or a certain angle according to clients' requirements. The difference will be the leg height at the ends.

| Model | Screw Conveyor Dia. (mm) | Conveyor Length (mm) | Capacity (t/h) | Power (KW) | Speed(rpm) |

| APLS250 | 250 | Custom Design | 20 | 7.5 | 60 |

| APLS200 | 300 | 25 | 11 | ||

| APLS400 | 400 | 30 | 11 | ||

| APLS500 | 500 | 50 | 15 |

AIPU Solids Control makes screw conveyors with auger diameters varying from 10 inches to 18 inches (10 inches, 12 inches, 14 inches, 16 inches, and 18 inches). And the screw conveyor length can vary from 12 ft to 48ft (12 ft, 24 ft, 36 ft, and 48 ft) as the standard model. Each auger is combined with a standard length of 12ft per section. For other customized diameters and transfer lengths, clients can contact GN Solids Control for customization.

As screw conveyor is rotation equipment, there must be necessary safety protections to meet HSE standards and to protect job site operators.

Firstly, the top of the screw conveyor will be covered and sealed by a metal plate or by gratings. On the one hand, it can prevent big matters fall down inside the screw conveyor which may break the auger impellers. Secondly, it can protect people's figures or feet from touching the screw conveyor while the auger rotating.

Secondly, AIPU Solids Control can equip Safety Grab Wires all long the auger length and ESD Devices (emergency stop devices) to start and stop the control panel in case of emergency.

AIPU Solids Contol can offer an Audio/visual alarm system on the auger control panel which will be automatically activated once the power is switched on followed by the actual auger startup with a safety delay time. Audio / visual alarm system to be in the OFF mode after some time once the auger starts operation.

It includes but is not limited to the following items. The motor, the gearbox, the coupling, the channel, the impeller or blade, the grade or sheet cover, the support leg, or the frame. If necessary, there is a control panel.

Some clients need the screw conveyor to perform at variable frequencies. The VFD can be achieved by the control panel, and also can be achieved in a mechanical way. Based on different clients' preferences, there are horizontal direction gearbox and vertical direction gearbox. The gearbox can be the helical bevel or the helical worm and wheel type.

we want to introduce a kind of equipment connected solid control system and waste management system. It is a screw conveyor, or name it auger. It is utilized to transfer solid waste or slurry from the solids control system (including shale shaker, mud cleaner, or centrifuge) to drilling waste systems for further treatment.

The drilling cuttings waste or the drilling fluids disposal discharged from solids control equipment need to be treated for the further drying process. The screw conveyor will help to transfer the disposal to a certain pit, cuttings dryer, or the filter press machine. For example, the auger feeder is set beside the tank and below the shaker discharge end. The auger feeder inlet position or channel beginning part can be fitted with a hopper in parallel to the discharge slide channel

Auger Feeder / Screw conveyor can help us get a convenient transfer drilling cutting and waste between equipment to further treatment center for the drilling waste. The auger feeder is not only used in oilfield waste management but also in other applications. Such as the chemical industry, construction industry, food industry, mining industry, and so on. The angle of the conveyor is customizable for the different work sites. For cuttings transfer, we usually use U type conveyor and a round tube-type conveyor.

As a professional manufacturer of solids control, we know better about the job site. We know how to design and configure an auger feeder is more convenient for users' operations. And from the raw material of steel to the different standard components (motors, gearbox) we select the high quality and excellent performance product

AIPU provides an optimal proposal for all the clients. Most of our orders place repeat orders of the reliable quality and stable performance. If you don't select us you may face risks of higher costs on operation or maintenance.

For any questions or demands, please feel free to contact AIPU solids. You will get a free offer on an optimal solution, you will get a professional proposal very soon.