Leader Dredger Co., Ltd |

|

12000m3 CAT Engine Dual Pump Capacity ISOCe Approved Cutter Suction Dredger For Ocen

1. Leader Dredger Dual Pump CSD LD12000 Technical Specifications

A . Dredging Features

| Standard dredging depth(m) Maximum mixture | 20m |

| capacity(m/h) | 12000m³/h |

| Solid capacity(approx) | 2000m³/h |

| Dredging pump mode | 800/800mm(32'/32") |

B . Principal characteristics

| Overall length(m) | 49m |

| Breadth(m) | 9.4m |

| Draught(m) | 1.8m |

| Discharge distance(m) | 2300m |

| Total dry weight approx(MT) | 420MT |

| Ladder length | 31m |

C . Dredge pump: Australia technology Pump

| By alloy cast iron material for better abrasion resistance, abrasive, hardness, more than68HRC. | Bigger working capacity, more efficiency, driven through gearbox. |

| Maximum mixture capacity(m/h) | 12000m³/h |

| Solid capacity(approx) | 2000m³/h |

D . Engine

| Main diesel engine(Cummins) | Cummins Q60 1864kw |

| Auxilary engine | Cummins KTA38 895KW |

| Total fuel consumption | ≤386kg/hr |

| Extra emergency generator set | 45kw(60Hp) |

2. Feature

| Easy to assemble and dismantle | Advanced profssional design |

| Deliver by road, rail or sea | Spare parts available |

| One man operation | Completely tested before deliverie |

| Advanced hydraulic system | with air conditioning |

| Water cooled diesel engines | Customizations on users'demand |

3. About Dual Pump Cutter Suction Dredger?

Cutter Suction Dredger is self-propelled or non self-propelled,portable cutter suction dredger,Hull can be dismantiled and re-assemble easily with box structure,equipped with horizontal shifting devices,cutter ,ladder lifting devices,spud devices,deck crane and so on.Widely used in sand-excavating,river dredging,desilting,reclamation for channels and land,port construction,etc.The hull uses dismantle and box-like structure, which equipped with horizontal shifting devices, cutter ladder lifting devices, spud devices, deck crane and so on. It can also be equipped with anchoring poles and trolley devices.We can manufacture dredger according to customer requirements. Different size and equipments, etc. All the dredgers have to be tested before delivery, make sure fast-assembly in clients working site.

4. Pre-Sales Service

1. Long-time after-sale service agreement with customers.

2. Rational and practical design according to customers' request.

3. Assemble and test the machine within the period as agreed in the contract.

5. After Sales Service

1.Free repair if quality problems emerge.

2.Free training of operation and maintenance for customers.

3. High quality accessories in low price.

4. Long-term following-up service.

6. Our Parts

- Cummins engine (primary and auxiliary)-usa

- Warman pump technology - Australia

- Rexroth hydraulic system - Germany

- Schneider electric system-Germany

The above parts have a 1-year manufacturer warranty and lifetime support.

7. Dual Pump Cutter Suction Dredger FAQ

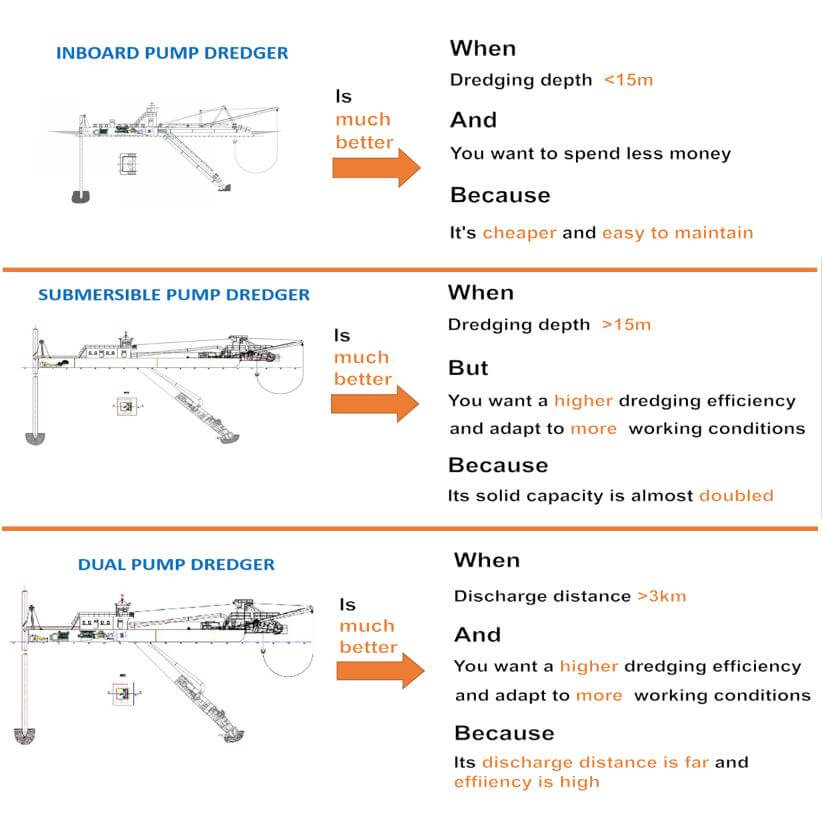

8. How To Choose Cutter Suction Dredger

9. Leader Dredger Customer

10. Delivery:

Carried by trucks to the loading seaport, and then by bulk vessels to the destination seaport.

11. Cutter Suction Dredger Testing Picture