|

|

[China]

Trade Verify

Address: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

Contact name:Jane

Changzhou DLX Alloy Co., Ltd. |

|

Verified Suppliers

|

|

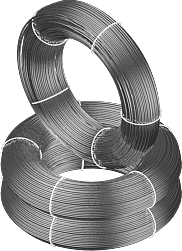

Nickel Alloys Wire Inconel 600 UNS N06600 Applied In Multiple Industries

Inconel 600 wire is a high-performance nickel-chromium-iron alloy wire with excellent corrosion resistance, oxidation resistance and high temperature strength. Its chemical composition mainly includes about 72% nickel, 14-17% chromium and 6-10% iron, as well as small amounts of manganese, copper and carbon. The high nickel content of this alloy makes it exhibit excellent corrosion and oxidation resistance in a variety of environments, including acidic, alkaline and high temperature environments.

Inconel 600 wire has the following features:

| Element | Percent |

| Nickel (plus Cobalt) (Min) | 72 |

| Chromium | 14-17 |

| Iron | 6-10 |

| Carbon (Max) | .15 |

| Manganese (Max) | 1 |

| Sulfur (Max) | .015 |

| Silicon (Max) | .5 |

| Copper (Max) | .5 |

Some typical applications are:

| AMS Number | Alloy | Cross Ref. Spec | Misc./Shape | |

|---|---|---|---|---|

| AMS 5540 Plate | Inconel 600 | - | Plate |  |

| AMS 5540 Sheet | Inconel 600 | - | Sheet |  |

| AMS 5540 Strip | Inconel 600 | - | Strip |  |

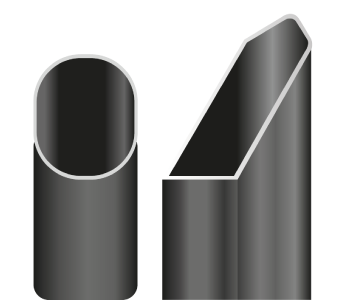

| AMS 5580 Custom Tube | Inconel 600 | - | Custom Tube |  |

| AMS 5580 Tubing | Inconel 600 | - | Tubing |  |

| AMS 5665 Bar | Inconel 600 | - | Bar |  |

| AMS 5665 Custom Tube | Inconel 600 | - | Custom Tube |  |

| AMS 5665 Ring | Inconel 600 | - | Ring |  |

| AMS 5961 | Inconel 600 | - | Wire |  |

Inconel 600 wire has become an indispensable material in the aerospace, chemical, marine and nuclear industries due to its unique combination of properties, and is widely used in occasions with extremely high reliability and performance requirements.