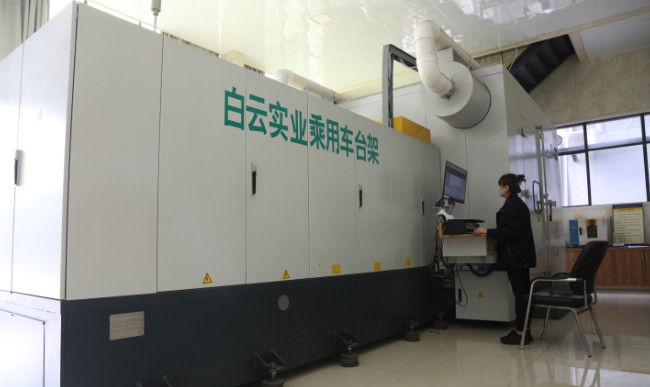

Zhengzhou Baiyun Industrial Co., Ltd. |

|

Non Asbestos Organic Brake Pads High Performance Under Link Testing

What is commercial vehicles?

A commercial vehicle is any type of motor vehicle used for

transporting goods or paying passengers. The European Union defines

a "commercial motor vehicle" as any motorized road vehicle, that by

its type of construction and equipment is designed for, and capable

of transporting, whether for payment or not:

(1) more than nine persons, including the driver;

(2) goods and "standard fuel tanks". This means the tanks

permanently fixed by the manufacturer to all motor vehicles of the

same type as the vehicle in question and whose permanent fitting

lets fuel be used directly, both for propulsion and, where

appropriate, to power a refrigeration system. Gas tanks fitted to

motor vehicles for the direct use of diesel as a fuel are

considered standard fuel tanks.

In the United States a vehicle is designated “commercial” when it is titled or registered to a company. This is a broad definition, as commercial vehicles may be fleet vehicles, company cars, or other vehicles used for business. Vehicles that are designed to carry more than 15 passengers are considered a commercial vehicle. Variations may exist from state-to-state on which "commercial vehicles" are prohibited on certain routes and lanes and between homeowner associations, which may employ broader definitions than their municipalities with regard to their own parking restrictions.

Broadly defined, a vehicle may be considered a commercial vehicle if it:

Belongs to a company or corporation

Is used for business, but is in an individual's name, such as a

sole proprietor

Is a leased vehicle and in the name of the financial institution

that owns it

Exceeds a certain weight or class and therefore, is "classified" as

commercial even though it may not be commercially used or

commercially owned. A weight rating of 26,001 pounds or more is

always considered commercial[3]

Is used to haul any hazardous material

A vehicle can be used for a business, if not exclusively, and

remain privately licensed, depending on the amount of time used for

business.

DAF | Daimler AG (Daimler, EvoBus Freightliner, Fuso, Mercedes-Benz) | Dana Holding Corporation | Ege Fren | Haldex | Hendrickson | Inver Press | Kamaz | Knorr-Bremse | Knott Group | Krone Group (gigant) | | Meritor | Paccar (DAF, Leyland, Foden) | Schmitz Cargobull | Tuna Stålrör | Valx | Volvo Trucks (RVI, UD Trucks, Volvo) | WABCO | Beinben-Truck | BPW | Brakes India Limited | Wuhan Youfin Auto Parts Co (Youfin) | Yutong | ZF Friedrichshafen

What is commercial vehicles brake ?

There are two types of brakes of commercial vehicles:

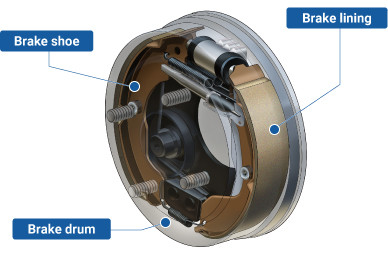

1) Drum Brakes

Drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum. Drum braking linings have brake drums that rotate with the wheels.

Brake shoes fitted with brake linings (friction material) which press against the drums from the inside to generate braking force (decelerate and stop) are set inside of the drums.

With this system, friction is generated by pressing the brake linings against the inside surfaces of the drums. This friction converts kinetic energy into thermal energy. Drum rotation helps to press the shoes and the lining against the drum with more force, offering superior braking force in comparison with disc brakes. On the other hand, it is very important to design the components so that the heat from the thermal energy is dissipated efficiently into the atmosphere.

There are three types of drum brakes depending on how the brake shoes are pressed on to the drums; leading/trailing shoe type, twin leading shoe type and duo-servo type.

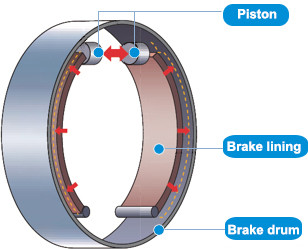

Structure of drum brakes

Drum brakes are a brake system with brake drums (rotor) which rotate with the wheels. Inside each drum are brake shoes fitted with brake linings (friction material). Pistons (pressure mechanism) press against the drums from the inside to generate braking force, thus making is possible to decelerate and stop the vehicle.

How drum brakes work

When the driver steps on the brake pedal, the power is amplified by the brake booster (servo system) and changed into hydraulic pressure (oil-pressure) by the master cylinder. The pressure reaches the brakes on the wheels via tubing filled with brake oil (brake fluid). The delivered pressure pushes the pistons on the brakes of the four wheels. The pistons press the brake linings, which are friction materials, against the inside surfaces of the brake drums which rotate with the wheels. The linings are pressed on the rotating drums, which in turn decelerate the wheels, thereby slowing down and stopping the vehicle.

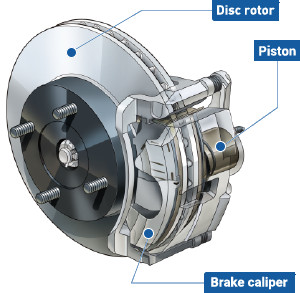

2) Disc Brakes

Brake rotors of disc brakes rotate with the wheels, and brake pads, which are fitted to the brake calipers, clamp on these rotors to stop or decelerate the wheels. The brake pads pushing against the rotors generate friction, which transforms kinetic energy into a thermal energy.

This thermal energy generates heat, but since the main components are exposed to the atmosphere, this heat can be diffused efficiently. This heat-dissipating property reduces brake fade, which is the phenomenon where braking performance is influenced by the heat. Another advantage of disc brakes is its resistance to water fade, which occurs when the water on the brakes significantly reduces braking force. When the vehicle is in motion, the rotor spins at high speeds and this rotational motion discharges the water from the rotors themselves, resulting in stable braking force.

Disc brakes are generally used in passenger cars, but due to their stable performance at higher speeds and resistance to brake fade, they are gradually spreading into the commercial vehicle segment, where drum brakes were traditionally chosen for their longer service life. There is increasing demand from customers for longer service life and higher quality, and Baiyun is committed to meeting them through further development of the disc brake’s reliability. There are two types of disc brakes.

The "opposed piston type disc brake" has pistons on both sides of the disc rotor, while the "floating type disc brake" has a piston on only one side. Floating caliper type disc brakes are also called sliding pin type disc brakes.

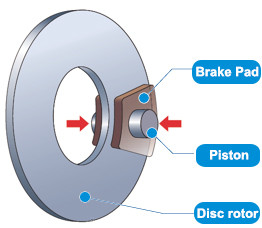

Disc brake construction

The brake rotor (disc) which rotates with the wheel, is clamped by brake pads (friction material) fitted to the caliper from both sides with pressure from the piston(s) (pressure mechanism) and decelerates the disc rotation, thereby slowing down and stopping the vehicle.

Data of BAIYUN Commercial Vehicles Brake Pads

| Product | Bus Brake Pads |

| Part No. | WVA29087/WVA29179/WVA29042/WVA29085 |

| Size | 247.7*109.7*30mm |

| Friction coefficient | 0.35~0.45 |

| Warranty | 80,000-100,000km |

How brakes work

When the driver steps on the brake pedal, the power is amplified by the brake booster (servo system) and changed into a hydraulic pressure (oil-pressure) by the master cylinder. The pressure reaches the brakes on the wheels via tubing filled with brake oil (brake fluid). The delivered pressure pushes the pistons on the brakes of the four wheels. The pistons in turn press the brake pads, which are friction material, against the brake rotors which rotate with the wheels. The pads clamp on the rotors from both sides and decelerate the wheels, thereby slowing down and stopping the vehicle.

ABOUT BAIYUN

Zhengzhou Baiyun Industrial Co., Ltd., is one of the leading auto friction braking enterprise in China, Top 10 enterprises of China Friction Material Industry and member of friction industry association. Since 1977, is a national high-tech enterprise with main products of brake friction material and brake products.

Baiyun will insist on the enterprise mission “create value for customers, create happiness for employees” continuously forge ahead, and create a more brilliant future

There are more than 1000 models brakes of Baiyun have obtained E-mark certification till now.Till now, Baiyun has become an important supporting supplier and partner of many famous domestic and overseas auto brands. Baiyun has also reached long term strategic cooperation with many famous domestic and overseas auto parts distributors.Baiyun will insist on the enterprise mission “create value for customers, create happiness for employees” continuously forge ahead, and create a more brilliant future

For more than 40 years, Baiyun focus on the R&D, production and selling of brake linings & pads for commercial vehicles and passenger cars, fighting for human traffic braking safety. Baiyun has passed ISO9001 Quality Management System and IATF16949 Auto Industry Quality System Certification. Long-term cooperation is established with international authoritative test organizations such as America LINK and GREEN to test Baiyun brakes regularly.

BAIYUN FACTORY & WORKSHOP