|

|

[China]

Trade Verify

Address: Luocun New Light Source Industrial Base, Shishan Town, Nanhai District, Foshan City, Guangdong Prov., China 528200.

Contact name:Sylar

Foshan Xiong Qi Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

Full automatic 10ml vial filling and capping machine

Characteristic of Full automatic 10ml vial filling and capping machine

The XQXL-2A represents a cutting-edge design in the realm of

automatic filling and crimping machines, specifically tailored to

meet the requirements of handling Penicillin bottles. Incorporating

an intelligent operating system, this machine revolutionizes the

operational ease, ensuring that even users with minimal technical

expertise can navigate its functions seamlessly. The sophisticated

design leverages advanced technology to streamline processes and

enhance overall efficiency.

The liquid filling component of the XQXL-2A boasts the

implementation of the XQX2 ceramic pump. This pump stands out for

its precision and versatility, enabling meticulous control over the

injection volume for each cycle by merely adjusting the angle of

the pump head. This feature guarantees extremely high measuring

accuracy, along with repeated consistency, thereby minimizing waste

and ensuring that each bottle receives the exact quantity of liquid

intended.

The crimping or riveting section of the machine has undergone

rigorous engineering, featuring a special material coating that

undergoes hardening treatment. This treatment significantly boosts

the durability and resilience of the crimping part, ensuring an

extended service life even under heavy-duty conditions. The robust

construction minimizes wear and tear, translating to fewer

maintenance requirements and consistent performance over time.

Moreover, the XQXL-2A is designed with modular components that

facilitate swift and straightforward installation. The equipment

leverages a mold-based setup, allowing operators to quickly and

effortlessly switch between different bottle types. This

flexibility makes the machine highly adaptable to varying

production needs and bottling requirements, ensuring that it

remains a valuable asset in diverse manufacturing environments.

1- Small size, layout size, functional module layout is reasonable

and complete, easy to maintain;

2- the two major functions of filling and capping are in-line

production, continuous operation, without manual assistance;

3- The operation of the machine actually only needs one person to

do the job (including feeding and receiving), which can greatly

save the cost of employment and the one-time occupation of

equipment

Technical data of Full automatic 10ml vial filling and capping machine

Target Products | Penicillin bottle |

Manufacturing speed | 28-35 PCS / minute |

Power | AC 220V 50-60Hz / 1.5kw |

Air range | 0.5-0.7Mpa |

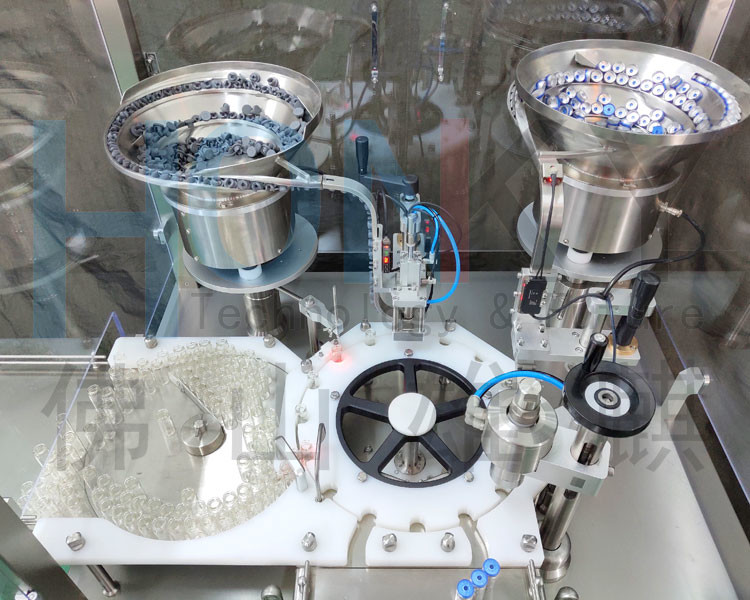

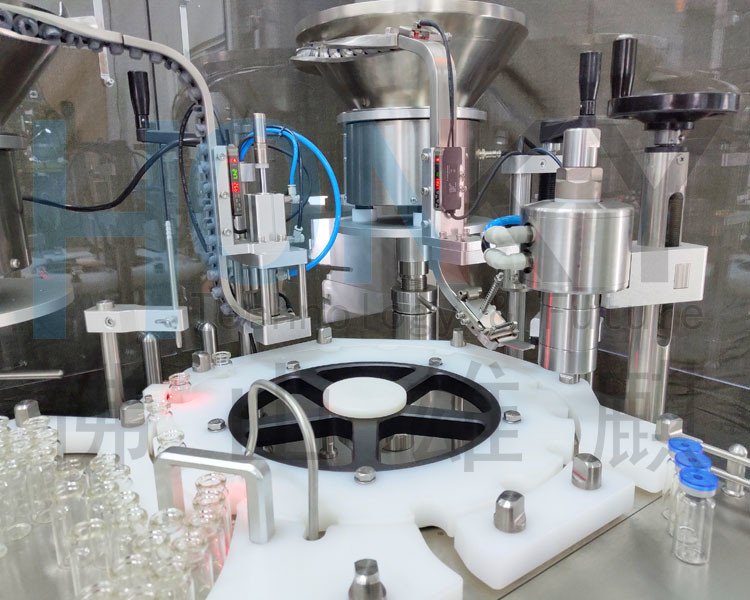

Product display of Full automatic 10ml vial filling and capping machine

The compatible design combines the filling, cap loading, and crimps

in one small space.

Filling, cap loading and crimping.

Finish product display.

Advantages for using the ceramic pump:

1. Low Friction, Increased Packing Life

2. Extreme Wear Resistance

3. Increased Corrosion Resistance

4. Improved Anti-Galling Surface

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support.

Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime

after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine

purchases. We will provide the user manual and videos to support

installing, debugging, operation of the machine, which will

indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.