Sinoma (Yichang) Energy Conservation New Material Co., Ltd. |

|

Fiber Cement Board Production Line /Eps Foam Cement Sandwich Panel Machine

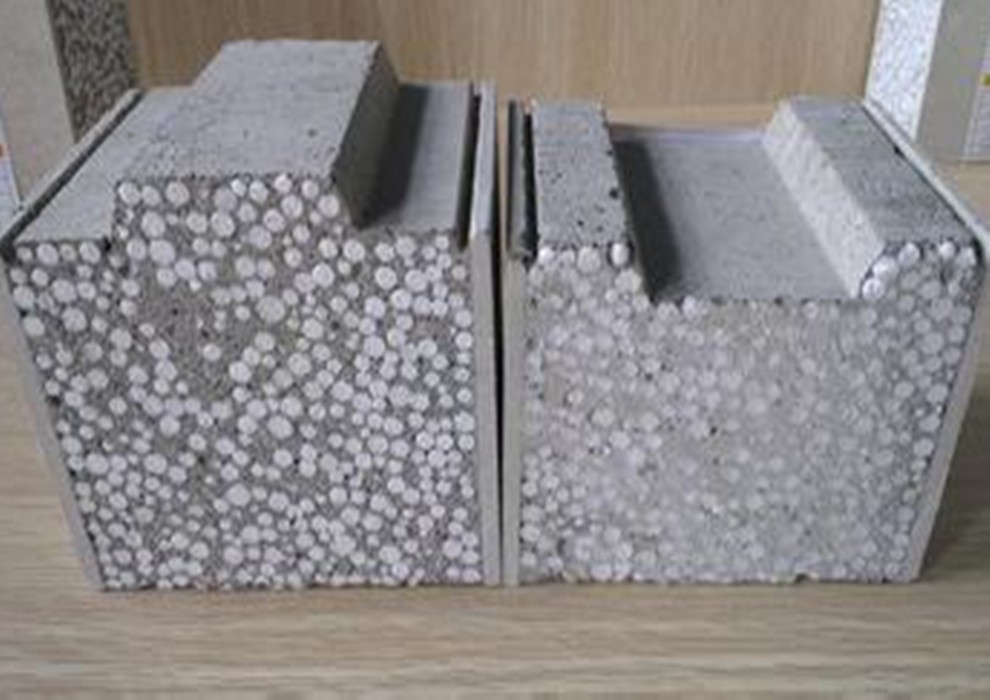

This machine is mainly used to produce the composite wall panels (with silicate calcium board as surface panel and with EPS grain, cement and fly ash as the mixed material in the middle) and suitable for both small and large manufacturing on production. It can produce 10 boards at one time.

Main Technical Parameters:

| No. | Test Item | China standard | Product test |

| 1 | Compressive strength | ≥3.5MP | ≥3.7MP |

| 2 | Drying shrinkage value | ≤0.6mm/m² | 0.37mm/ m² |

| 3 | Hanging force | ≥1000N 24hours No 0.55mm crack | ≥1000N 24hours No 0.55mm crack |

| 4 | shock resistance | No damaged that Impacting of 30kgs sandbag five times | No damaged that Impacting of 30kgs sandbag five times |

| 5 | The bending failure load | ≥1.5 times of wallboard | ≥2.5 times of wallboard |

| 6 | radioactivity | Inner radiation index Ira≤1.0 Outer radiation index IY≤1.3 | Inner radiation index Ira≤1.0 Outer radiation index IY≤1.3 |

| 7 | density | ≤90kgs/m² | ≤60kgs/m² |

| 8 | Air insulation of sound | ≥35dB | ≥43dB |

| 9 | heat transfer coefficient | No | ≤2.0W/ m² . k |

The cost for materials

Aerated hollow core panels (The raw materials are cement, fly ash, foaming agent and additive) Cost:USD2-3/m2 Weight:40kg/m2 compressive strength:7MPA-15MPA | |

Double line hole panels. (The raw materials are cement, fly ash, foaming agent and additive) Cost:USD2.5-3.5/m2 Weight:50kg/m2 compressive strength:7MPA-15MPA | |

Sandwich wall panels (The raw materials are cement, Polystyrene foam board and additive) Cost:USD3-4/m2 Weight:35kg/m2 compressive strength:5MPA-10MPA |  |

EPS Sandwich Panel (The raw materials are fiber cement board, cement, polystyrene particles, and additive) Cost:USD3-4/m2 Weight:60kg/m2 compressive strength:10MPA-20MPA |  |

Fiber cement board production line /eps foam cement sandwich panel machine

| thickness(mm) | width(mm) | length(mm) | quantity(block/set) | area(squ.m/set) |

| 60 | 610 | 2440 | 58 | 86.3 |

| 75 | 610 | 2440 | 50 | 74.4 |

| 90 | 610 | 2440 | 40 | 62.5 |

| 120 | 610 | 2440 | 34 | 50.6 |

| 150 | 610 | 2440 | 28 | 41.6 |

| 180 | 610 | 2440 | 24 | 35.7 |

Main features

Reduce the occupation area of the wall

Sound insulation wall and fire protection wall.

Good sound insulation

Good water proof

Smooth products surface

Environmental friendly

Fiber cement board production line /eps foam cement sandwich panel machine

| Advantages | ||

| Number | Item | Content |

| 1 | Low cost | Low labour and material costs |

| 2 | Long life | Up to 60 years |

| 3 | Recycling use | Reused for more than 10 times |

| 4 | Flexible layout | Layout adjusted according to your requirement |

| 5 | Environment protection | Environment-friendly materials used |

| 6 | Safe & Stable steel structure | Earthquake proof & Wind resistance |