Hyzont(Shanghai) Industrial Technologies Co.,Ltd. |

|

Verified Suppliers

|

|

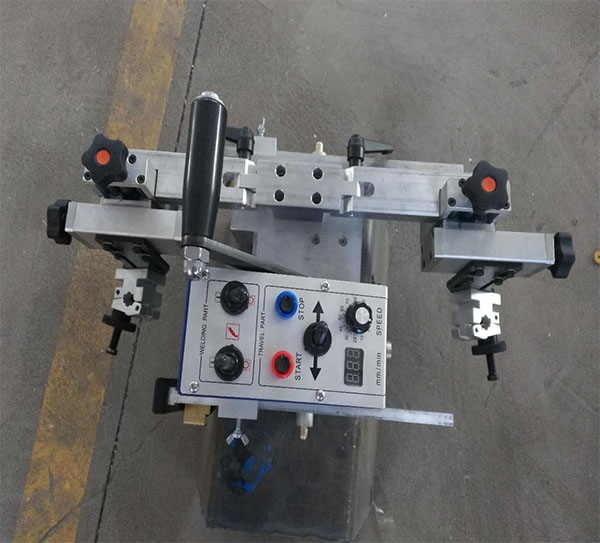

U-Shap double welding gun MIG/MAG automatic welding tractor

CO2 automatic welding trolleys are widely used in industries such

as ships, bridges, locomotives, steel structures, and

petrochemicals, and are suitable for welding various welding

structures, such as the welding of reinforcing ribs, rib plates,

intersections, box beams, and so on. Its main advantages include:

Reduce labor intensity and improve working environment

Improve work efficiency by 1.5 times that of manual welding

To avoid poor weld quality caused by human factors, the defect rate

of manual operation is generally around 20%, while using an

automatic welding trolley does not result in a welding defect rate

as a result

Therefore, its comprehensive benefits are nearly 200% higher than

manual welding

High degree of automation ensures the stability of welding quality

No need for highly skilled technical workers

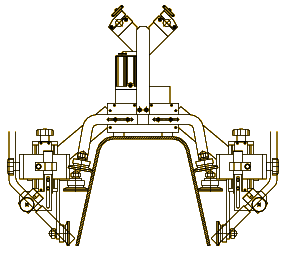

The U-shaped double-sided welding automatic car is designed for the

overlap between U-shaped parts and flat plates. When working, the

car walks on the U-shaped surface and uses two welding guns to weld

simultaneously, which not only improves work efficiency but also

reduces welding deformation.

characteristic

1) The car is suitable for double-sided continuous welding (corner

joint, overlap) of U-shaped reinforcement. Equipped with two

welding guns, controlled by the same control panel, it is best to

use the same welding specifications for both welding guns.

2) No need for track walking, simple setup.

3) Adopting a mechanical tracking system. There are guide wheels

with spring extension mechanisms on the walls and flat plates of

U-shaped parts, which can flexibly track welds.

4) The bottom and back of the car are equipped with photoelectric

sensors, which can automatically stop when the car is welded to the

end of the U-shaped reinforcement, making it convenient for workers

to operate multiple equipment at the same time.

5) The car can walk on surfaces with a slope of less than 20 ° but

more than 10 °.

6) Replacing the welding gun fixture can be used with water-cooled

and air-cooled welding guns.

7) You can customize the car according to the size of different

U-shaped reinforcements.

8) Equipped with a permanent magnet, it works better with the guide

wheel to ensure that the welding gun travels along the weld seam.

Applicable environment

Suitable for lap and corner joints of U-shaped parts

Specification

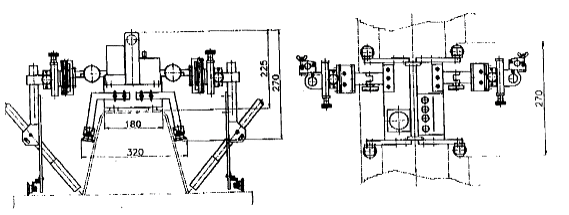

| Item | Note | |

| Welding Tractor | Moving Type | 4 wheels moving |

| Size | 320 ×270 × 270 | |

| Application | U Shape reinforcing rib | |

| Welding Gun | Level :65㎜,vertical :65㎜ welding gun moving:±150;adjust angle:±450. | |

| Weld seam tracking | lead wheel | |

| Weight | 13㎏ | |

| Control Box | Function | moving speed :0~1200mm/min. |

| Power input | AC 220 | |

Connection of the machine

Install

(1) Installation conditions:

1. The necessary tools for welding are the welding power supply and wire feeder device;

2. Welding power supply (AC 220V) for walking and control of KA-C1;

3. CO2 gas tank for welding;

4. Direct welding gun for CO2 automatic welding;

5. Basic tools for other necessary tasks;

(2) System connection method

1. Install the track, which must ensure that the welding direction of the trolley is parallel to the weld seam

2. Install the trolley and use the installation handle to clamp the track wheels of the trolley onto the track

3. Install welding wire on the wire feeder and pull it to the end of the welding gun

4. Connect the welding gun port to the wire feeder

5. Connect the control power cable to the 8P port on the control panel of the car

6. Connect the control power cable to AC 220