Hangzhou Hangyang Cryogenic Liquefaction Equipment Co., Ltd |

|

Argon plant KDONAr-2000/5000/45Y Ar Gas Air Separation Unit O2 N2 Generation Plant Cutting Gas

Specifications:

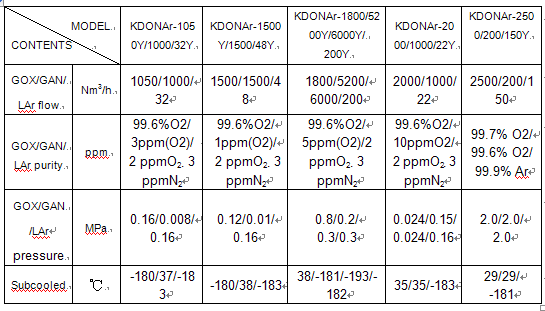

10~150 Nm3/h LAr KDONAr Series Argon Plant List

Typical Product: KDONAr-2000/5000/45Y Argon plant

Output, purity and pressure

| Flow (Nm3/h) | Purity | Pressure MPa(G) | Subcooled (℃) |

GOX/GAN/LAr | 2000 Nm3/h /5000 Nm3/h/45 Nm3/h | 99.6% O2 /10ppmO2/ 2ppmO2,3ppmN2r | 0.023/0.016/ 0.16 | 13/13/ -181 |

Description:

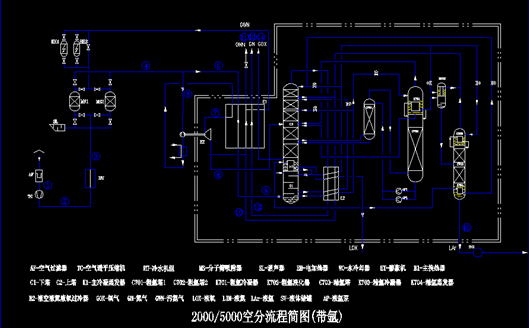

In the air separation plant, the flow path of air is that : air→ air filter→ air compressor→ air cooling system→ molecular sieve adsorber→ main heat exchanger→ lower column. After going into lower column, the components of air are changed, and the nitrogen gas is separated from air at the top of lower column. The nitrogen gas transfer the heat to liquid oxygen in the condenser evaporator, and on the premise of certain temperature difference between liquid oxygen and liquid nitrogen, the homologous liquid oxygen pressure can be calculated. Thus the pressure line is extended to: lower column→ main condenser→ upper column. By this way the pressure of waste nitrogen and nitrogen at the top of upper column can be confirmed. Then, following the waste nitrogen flowing path: upper column→ subcooler→ main heat exchanger→ molecular sieve purification system heater→ molecular sieve adsorber→ atmosphere. There are two pressure transforms of air during these flow paths: one is compression of compressor, the other is pressure mapping of main condenser; the rest pressure changes are coursed from the resistance of equipments, pipelines and valves.

Applications:

Competitive Advantage: