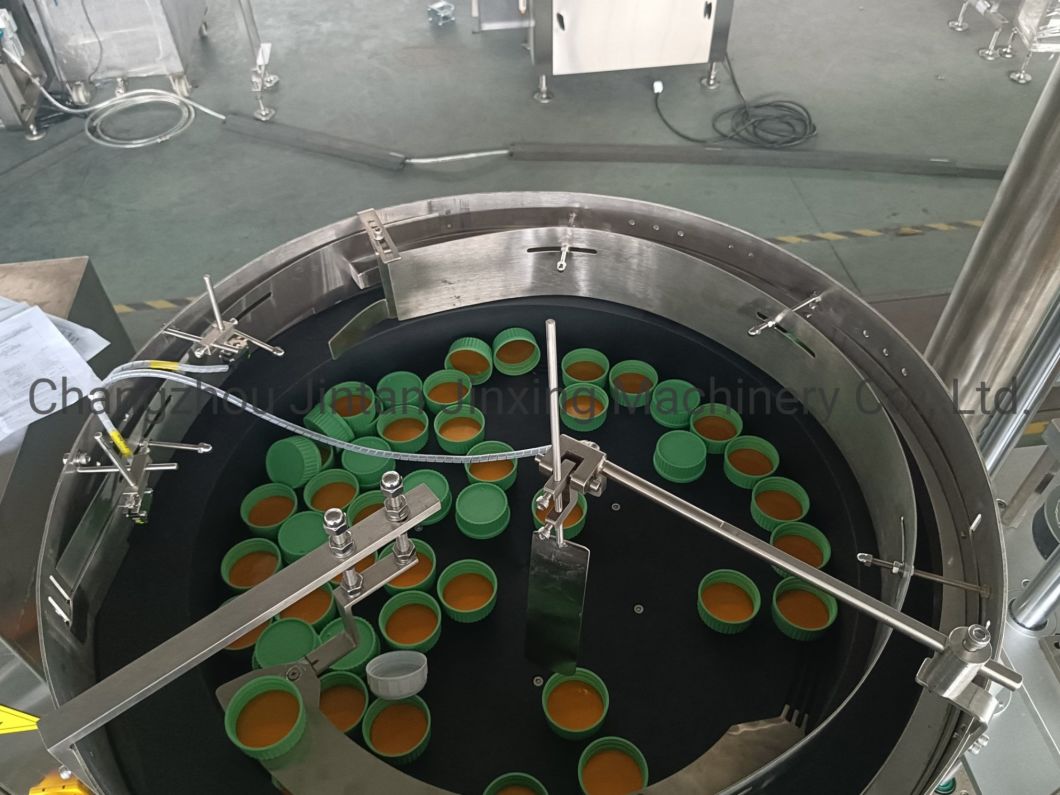

General purpose lid-sorting machine, suitable for a variety of

different sizes of LIDS, quick lid-sorting speed, high efficiency.

Only adjust the width and height of the channel to replace

different types of LIDS, without replacing accessories.

When the cap passes under the cap, the cap is attached to the cap,

and the belt holding the bottle body synchronously makes the cap

spinning process more stable.

Main Features

Automatic linear screw capping machine. It's suitable for various

material and figure containers . Such as plastic bottles , glass

bottle , and metal bottle .There is no need to change parts when

changing the bottle shape, as long as the position of some parts is

adjusted.The machine is simple in structure and easy to

adjust.Won't hurt the bottle or the cap when capping. The speed of

cap sorting,conveyor,bottle clamping belt and capping screws can be

stepless speed regulation to meet the tightening requirements for

various bottles and caps.Four groups of frequency converters

control the cover divider, rolling wheel speed, conveyor belt speed

and synchronous belt speed respectively, each part can be adjusted

separately. With different type of this machine,we can change the

screw type into pressure capping type machine.So that it can fix

for pressure capping. The machine is made of SUS304/316 stainless

steel , also applied to GMP standard requirement .

(custom-tailoring diversified for special specification )

Enterprise brief introduction

Changzhou Jintan Jinxing Machinery Co., Ltd. was established in

2004, with more than 15 years of machinery manufacturing

experience. The company is located in Jintan Economic Development

Zone, Changzhou City, Jiangsu Province. We are committed to

pesticide, chemical, food, daily chemical packaging machinery

development, research and production. The main products of the

company are: automatic, semi-automatic bottle unscrambling machine,

filling machine, capping machine, labeling machine, unpacking

machine, packing machine, stacking machine, etc., and provide

customers with the solution of the whole production line. The

company's products sell well in more than 20 provinces and cities

throughout the country, and with strong technical force, advanced

equipment, scientific management system and perfect after-sales

service exported to more than 30 countries and regions.

Welcome every customer at home and abroad to visit Jinxing

machinery, guide the work, thank you!Pre-sale service

1. Support product customization, any requirements you need can be

customized according to your requirements.

2. Sample test on our machine.

3. Provide business consulting and technical support, as well as a

free professional filling solution

4. Make a machine layout for customers based on customers'

factories.

After-sales service

1. Manual book.

2. Videos of installation, adjusting, setting, and maintenance, are

available for you.

3. Online support, or face-to-face online communications, are

available.

4. The engineer overseas services, are available. The tickets,

visa, traffic, living, and eating, are for customers.

5. During the warranty year, without human-being broken, we will

replace a new one for you.

The sample service

1. We can send you the production video of the machine.

You are welcome to visit our factory at any time. You can see the

machines in operation here. We'll arrange to pick you up when you

come.

Customized service

1. We can design the machine according to your requirements

(material, power, filling type, bottle type, etc.).

2. We will also give you professional advice.

After-sales service

1. We will provide the BILL of lading in time to ensure that you

can get the qualified machine quickly.

2. After you complete the preparation conditions, our engineers

will go to your factory for installation, testing and training.

We provide one year warranty, free of charge to provide vulnerable

parts.

Successful cases

Through efficient cost control, we find the right balance with our

customers: diversified production range, high-end packaging form.

At the same time, the efficient operation of equipment improves the

market competitiveness of enterprises. Wangji will provide

customers with customized beverage production line solutions,

including bottle design, label design, beverage preparation,

packaging system and advertising solutions of the best solutions,

to help customers easily start businesses, easy access to the

market.

FAQ:Frequently asked Questions:

Q1. May I visit your factory?

A1: Ok, our factory address: No.158 Huaxing Road, Jintan, Changzhou

city, Jiangsu Province, China.

Q2. If we have a new product sample, could you help analyze and

design the machine?

A2: Yes, our technicians can help analyze, design and test the new

products you offer.

Q3. What can you buy from us?

A3: Bottle unscrambling machine, bottle washing machine, filling

machine, capping machine, labeling machine, unpacking machine,

packing machine.

Q4. What spare parts can you provide?

A4: After we have installed all the equipment, we will send you a

list of spare parts for your reference.

Q5. What services can we provide?

A5: Delivery terms accepted :FOB,FCA,EXW;

Currency of payment accepted: USD, Euro;

Payment methods :T/T, TELEgraphic transfer, PayPal;

Language: English, Chinese