Cangzhou Kading Carton Machinery Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

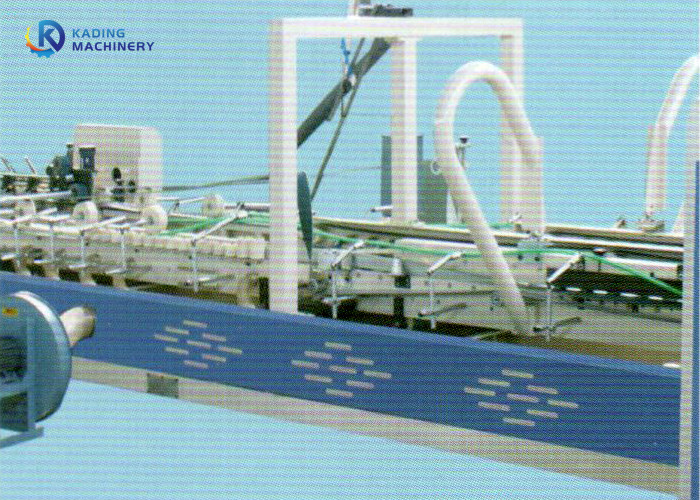

The most critical step in corrugated box packaging production is shaping, so in the entire production line, the folder gluer machine is the most important machine. The fully automatic carton gluing machine is a mechanical device that automatically completes the processes of cardboard feeding, deviation correction, marking, gluing, folding, pressurization, alignment, counting and discharge at one time. It shapes a piece of cardboard into a carton. Today, let’s learn about folder gluer and enter the corrugated box molding industry.

| Max.size(A+B)x2 | 2600mm | Min.length A | 170mm |

| Min.size(A+B)x2 | 600mm | Max.height D | 900mm |

| Max.size(C+D+C) | 1200mm | Min.height D | 150mm |

| Min.size(C+D+C) | 270mm | Max.tongue width E | 40mm |

| Max. rock cover C | 60mm | Max feeding height | 900mm |

| Min rock cover C | 380mm | Max.length A | 770mm |

| Max width B | 530mm | Min.width B | 130mm |

| Working speed (nail/min) | 800mm | Nail number | 1-99 |

*Machine's specification is subject to the final confirmation of seller and buyer.

Advantages of the machine

The characteristics of the folder gluer machine can enable carton

companies to reduce their reliance on a large number of manual

gluers, save working space, and improve work efficiency and product

quality. Whether it is large-sized cardboard or small-sized

cardboard, it can be folded into cartons. To some extent, this is

an improvement from a high level of carton packaging.

Working principle

The latter section automatically counts of the folder gluer

machine, and the number of finished products (1-99) can be stacked

and sent to the end of the conveyor according to the set number for

easy bundling. The fan-assisted air-drying function speeds up

carton gluing and reduces the production of defective products. It

only takes one person to operate from the gluing of semi-finished

products to the placement of finished products. The operation is

simple and convenient. The paper feeding part automatically counts,

and the stacked bundles are automatically sent out and bundled to

avoid the phenomenon of scissors in the cartons.

characteristics of machine

The folder gluer machine has adequate protective measures to avoid

operating hazards. There is sufficient and smooth space for

personnel to transfer cardboard to the paper conveying bed. The

size settings are easy to adjust, including the settings of the

baffle, origami arm, cardboard gap, and counting discharge

quantity. The folder gluer machine is equipped with a support

device to prevent large cardboards from sagging due to gravity when

stacked. Equipped with a paper feeding and suction device, even

curved cardboard can be conveyed smoothly. Origami forming rods can

overcome the effects of poor creasing quality or uneven creasing

depth. The origami conveyor belt of the semi-automatic folder gluer

is equipped with guide bars, which cooperate with the guide grooves

of the pressure roller to prevent the origami belt from snaking. It

is equipped with a fine-tuning control device for the speed of the

lower origami belt, which can match the characteristics of the

carton and avoid large or small mouth or fishtail-shaped skew.

Automatic Folder Gluer Stitcher Machine Description

1. Suitable for 3 ply, 5 ply and 7 ply single-piece carton nailing and bonding;(for double pieces machine, please ask our sales for more details)

2. Nail pitch range: 40-500MM;

3. The nailing angle is 40 degrees;

4. Single and double nails can be adjusted freely, suitable for

international #17 and #18 nail wires;

5. Use the forearm sorting function to change the order quickly,

and the paper is in good order;

6. The wire feeding machine adopts intelligent wire feeding, which

has little wear on the wire wheel;

7. The computer system adopts servo motor to ensure the stable

operation;

8. The speed can reach 1050 nails/minute;

9. Low equipment failure rate (using soft bottom mold structure);

10. The swing nail head runs smoothly.

Paper Feeding Unit

Folding Unit

Stitching Unit

Stacking Unit

Cangzhou Kading Carton Machinery Manufacturing Co., Ltd's factory was founded in 2009 and is located

in Dongguang County, Cangzhou City, Hebei Province.

We are a manufacturing enterprise that produces carton making machinery, with 30 expereinced workers,

2 professional product tester, and 1 core skilled carton printer engineer; Besides, we also have a sales team

composed of a group of young people with forward thinking, we can make a professional product plan for you

according to your product needs.

Our company's self-produced product lines include carton printing machines, carton die-cutting machines,

and carton slotting machines; Our advantageous products include Carton stitching machines, Folder gluer

machines, Flute laminating machines, Single facer machines, etc.

If some related products you need are not produced by ourselves, with our mature product supply chain

system, we will also help you purchase products that satisfy you with the most competitive price and the

most guaranteed quality as the standard.

In addition to our own foreign trade business, our factory also cooperates with many trading companies,

so our products are exported to dozens of countries such as the Middle East, Africa, Southeast Asia, and

the European Union, and are well received by the majority.

There are also many brand&branded manufacturers among our customers, these factories are very relieved

to entrust the production of some products to us, which is enough to show that our quality and production

conditions are trustworthy.

Cooperate with us, benefit together!

Q: Are you a factory or a trading company?

A: We are a direct manufacturer that is located in Dongguang county,

Cangzhou city. Welcome to visit our factory!

We can also have video call if you’d like an online factory tour.

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q: How many languages does your machine support?

A: Our machine supports all the languages.

Q: How long it will take to produce machine?

A: Delivery time largely depends on the machine type, for some small

machine like manual stitching machine, manual

banding machine etc, usually we have stock available.

But for the large machines like carton printing die cutting

machine, automatic stitching machine etc, it usually takes

around 35-50 days to produce.

Q: Can we visit your factory?

A: Sure, welcome to pay a visit for our factory, we will pick you up

from airport, and will provide accommodation.