Qingdao Yonghui Packaging Machinery Co.,Ltd |

|

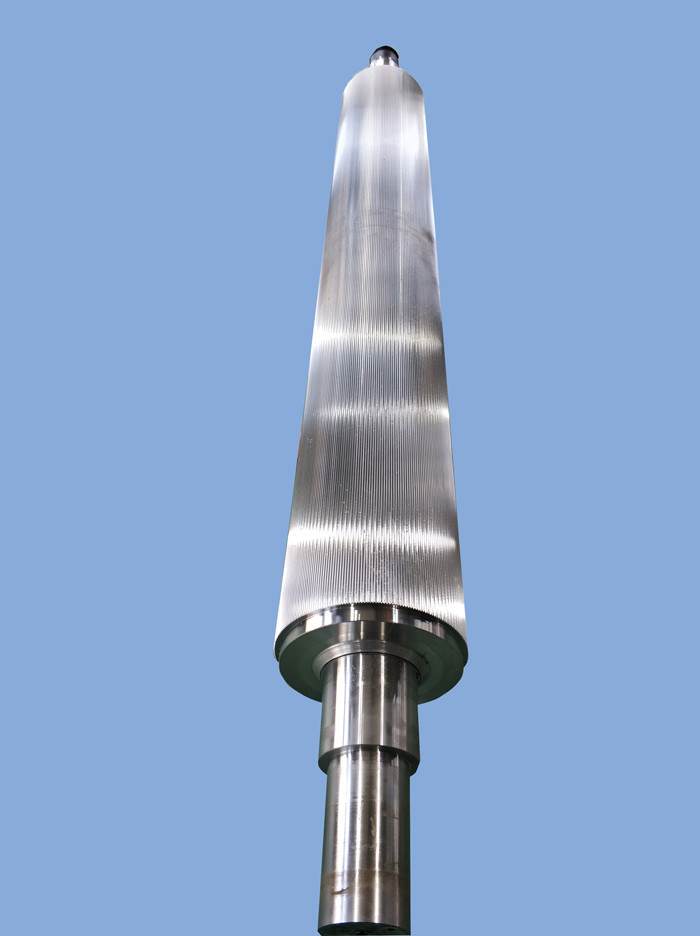

Fuli Hard Chrome Plated Roller Corrugated Packaging Machinery Parts

| Product name | Corrugating rolls, corrugated roller |

| Material | 50CrMo |

| Application | Single facer, corrugator machine |

| Diameter | 200-600mm |

| Width | 1000-2800mm |

| Flute Profile | A, C, B, E, F, G, N, O |

| Heating Treatment | Intermediate frequency quenching treatment |

| Hardness | ≥HRC58 after heating treatment, harden layer 8-12mm |

| Coating | Tungsten carbide, hard chrome 0.06-0.08mm |

| Corrugator line | BHS, Fosber, BW Paper System, Hsieh Hsu, K&H, JS, Fuli, Wanlian, Taiwan Mingwei, Chinese Mingwei, Meiguang, Dongguang, Dpack, Xinguang, Xieyang, Shengli, Indian machine, etc. |

Application:

Corrugating rolls are the core element of each corrugator and are essentially responsible for the quality of the corrugated board and the productivity of the corrugator.

Our Advantages:

☆ The domestic first-class technology and core operating team, each member has rich experience with processing more than 5000 sets of corrugated roller. Depending on the mature stable Taiwan craft technology and the advanced international technology, we offer the optimized design of corrugating roll flute profile totally according to costumer’s requirement.

☆ The CNC intermediate frequency heat treatment quenching machine adopts the foreign corrugating roll quenching technology and makes the hardness of the substrate reach more than HRC58 degrees, meanwhile it retains the toughness and maximizes the anti-thermal deformation of substrate to ensure the stability of corrugating rolls.

☆ The leading domestic high precision and high performance CNC corrugating roll precision grinders, lathe, planer, and other equipment are equipped with Germany's Siemens control system, increase grinding accuracy in the maximum.

☆ With the mature of tungsten carbide plating technology, the most advanced tungsten carbide coating equipment Praxair JP8000 , as well as high quality imported Praxair tungsten carbide powder, the abrasion performance of corrugating roll is extreme and maximize the extension of the service life of the corrugating roll.

How To Store Corrugated Hard Chrome Plated Roller Well??

| 1 | Store in dry places.The surface of corrugating rolls is not compact structure. The permeation and corrosion of water and steam will cause unusual falling off of coating.

|

| 2 | Apply silicon oil. The silicon oil is valid for 3 months. If you don’t use corrugating rolls for a long time, silicon oil must be applied to the rolls regularly to avoid unusual falling off of coatings caused by the permeation and corrosion of water and steam.

|

| 3 | Keep the surface clean. If you put the corrugating rolls in the warehouse, the surface should be cleaned and applied silicon for later use.

|