Cangzhou Gerun Machinery Co.,Ltd |

|

Verified Suppliers

|

|

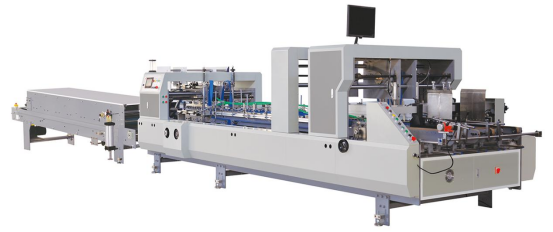

Automatic single correction high speed box folder gluer

I. Machine overview

1. Automatic single correction high speed box folder gluer overview

This series of folder-gluing machines is a high-speed folder-gluing machine customized by our company according to the production needs of various box types in the actual production process of our customers. Taking customers' products as the starting point and providing professional and tailor-made solutions to maximize the value of your products is Jinnuo's mission. With many years of experience in the packaging field, it is our obligation to fulfill our customers' needs as much as possible.

This series of high-speed folder gluers are equipped with independent paper feeding drive system, single correction system, PLC touch screen human-machine interface control system, paper feeding vibrating paper separation system, wireless remote control remote control system, independent electric adjustment system of each guide plate, 19-inch LCD Monitor monitoring system.

This series of high-speed folder-gluing machines are mainly suitable for small packaging, such as cosmetics, medicines, wine boxes, CD bags, express bags, four-corner and hexagonal boxes, other cardboard and micro-corrugated packaging (different machines can be customized according to different box types). The box making process is fully automated according to different box models, from paper feeding, pre-folding, bottom folding, gluing, folding to collection. And the whole process is continuous, stable and reliable, with high working speed and low energy consumption, simple and convenient operation; at the same time, it has the advantages of beautiful appearance, compact and novel structure, low noise and long service life. It is an ideal carton forming equipment.

2. Machine features and introduction to each part

①Overall Equipment:

a.The machine base is made of an integral steel plate. The thickness of the main wall panel is 16mm. All of them adopt laser cutting technology and have undergone cold and heat treatment. The whole machine has good rigidity.

b.The whole machine adopts modular design, with flexible function selection. Modules can be selected according to customer box type requirements.

c.The machine transmission adopts Sino-foreign joint venture chain, which has high speed, accurate and stable transmission, minimum noise and long service life.

d.The machine has good stability and the speed can reach 220m/min

Paper feeding department:

e.The paper feeding section adopts an independent motor for paper feeding, making paper feeding easier and smoother.

f.3 sets of paper feed knives to meet the paper feeding needs of various weight boxes.

g.The multi-level track ensures the verticality of the cardboard and ensures that the paper feeding is not skewed. The unique structure makes the adjustment of the cardboard easy and convenient.

h.Pneumatic knife lift shortens the time for adjustment and box change.

i.The vibration device cooperates with the motor to quickly, easily, continuously and automatically feed paper correctly.

j.The paper feed belt adopts an annular seamless beef tendon conveyor belt, which has strong wear resistance. At the same time, the machine structure adopts independent transmission, making it very convenient and quick to replace the paper feed conveyor belt in the later period.

②Bottom paste cylinder:

a.The lower paste cylinder is set up with one left and one right, and different rubber wheel thickness can be equipped according to the width of the glue opening of the customer's box type.

b.The paste cylinder is made of strong, durable stainless steel. And after finishing. The amount of glue can

be accurately controlled to ensure that the high-speed operation part of the glue.

③The folding part:

a.The left and right sides complete the second fold 180 degrees. The fourth fold is 180 degrees completely combined.

b.The folding part of the differential correction system, the special design of the folding part of the left and right conveyor belt speed can be adjusted to ensure straight line transportation. Can effectively reduce the case of box forming scissors.

c.The upper row pulley belt of the folding part is equipped with a power device to achieve the speed difference between the upper and lower belts resulting in paperboard slip.

d.Equipped with a set of left and right folding knives.

④Pressure transfer part:

a.Photoelectric counter automatic kicking paper, water spraying dual purpose system. And a paper stopper detection device.

b.The upper and lower belts are freely telescopic and convenient to adjust, making the carton of each shape stacked more neatly and smoothly when entering the conveying part.

c.Equipped with mechanical patting device, so that there will be no scissors phenomenon in the production of flat express cartons. And the mechanical transmission has the characteristics of long and stable life.

⑤Conveying part:

a.The main wall panel of the conveying part adopts 12mm, and adopts laser cutting technology, and is treated by cold and hot, and the machine has good rigidity. The conveying length reaches 6m, and the long-distance design can extend the bonding time of the carton and improve the bonding quality of the carton.

b.Pneumatic pressure regulation, easy to adjust, can effectively ensure the uniform pressure of the fit.

c.Automatic and manual two modes one-click switch, to adapt to the production needs of various box types.

d.The upper and lower independent modular design of the conveying part can move relatively forward and backward to adapt to a variety of different length boxes.

⑥electrical system:

a.The machine is controlled by PLC, easy to operate; PLC and touch screen adopt Chinese famous brand Inwitten, stable and reliable, low failure rate. The whole machine adopts multi-frequency converter, and the control is more flexible and convenient.

b.The main drive motor adopts frequency conversion motor, which has the advantages of energy saving and high efficiency, wide speed adjustment range, stable starting and braking, improving production efficiency and reducing the maintenance cost of mechanical equipment.

c.The control panel layout is reasonable, and each module has a control panel.

d.The 19-inch LCD monitor can monitor the production process of the machine in the paper feeding department, making it more convenient for the captain to check the whole operation process.

I. Technical specification

| TECHNICAL PARAMETERS | ||||||

| MODEL | 650 | 850 | 1050 | 1250 | 1450 | 1650 |

| Paper material | Cardboard 210-800gsm,A/B/C/E/F flute and 5 ply board | |||||

| Max.speed | 220m/min | |||||

| Way of folding | First fold and fourth fold is 180 | |||||

| Power supply | 3P 380V 50HZ | |||||

| Blank width | 850mm | 1050mm | 1050mm | 1250mm | 1450mm | 1650mm |

| Length x Width x Height | 13mX1.4mX1.6m | 13mX1.6mX1.6m | 13mX1.8mX1.6m | 13mX2mX1.6m | 13mX2.2mX1.6m | 13mX2.3mX1.6m |

| Net Weight | 3.8t | 4t | 4.2t | 4.3t | 4.5t | 4.8t |

| Total power | 9KW | |||||

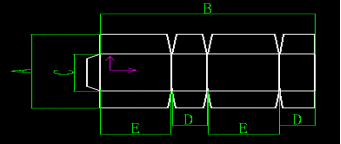

| Normal box type configuration specifications | |

| Model | 1050Type |

| B | 260-1050 |

| D+E | 130-525 |

| A | 120-1500 |

| D min | 30 |

| C min | 70 |

Our company

Product packaging

FAQ:

Q1: How is the warranty of the machine?

A: Warranty period: 12 months from the shipping date of machine.

Warranty will be not valid if machine subject to misuse or

accidental damage or operator's error. During the valid time, we

will supply spare parts. If you have any other questions, Kindly

contact us and we will reply you through product's photos and

videos to make every detail clear.

Q2: How about the after-sale service?

A: 1) TM online 24 hours, also contact by email, skype, wechat,

whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.

Q3: Is it safe on the payment for me as we are the first

cooperation?

A: We can do the trade assurance on Alibaba, which will guarantee

your products receiving, we also accept other safe payment way as

you want.

Q4: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set, as our product is machinery

equipment, it is difficult to send you samples, if you have any

questions about the products, please feel free to contact us for

more detail, we are glad to provide you more information such as

specifications, video, etc.