Jiangyin Electrical Alloy Co., Ltd. |

|

Verified Suppliers

|

|

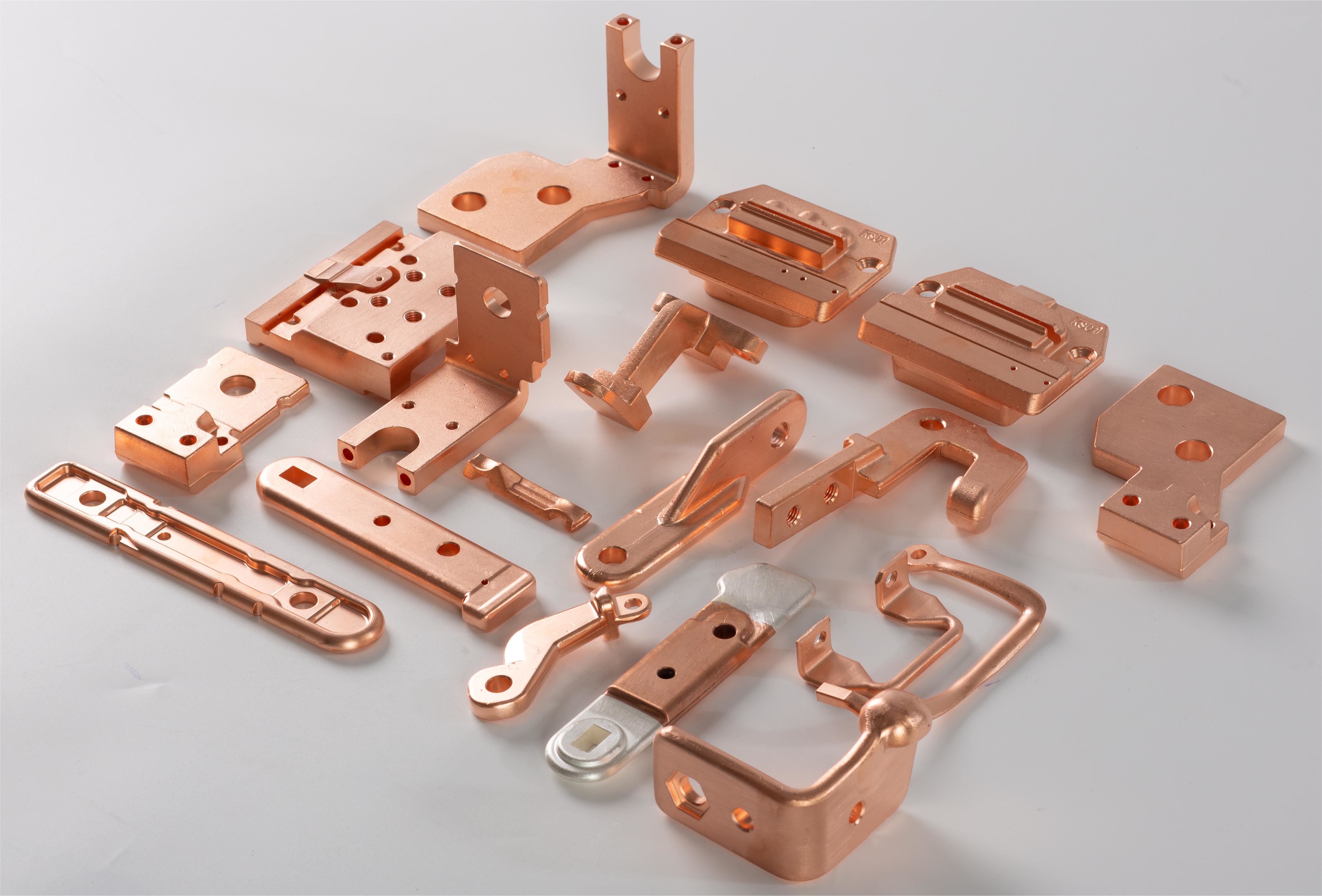

High-Conductance Forged Copper Electronic, Electrical, Automotive

Wrought copper is produced by shaping copper in a forging process. This alters its shape in certain areas to achieve the desired structure, while improving its mechanical properties and structural integrity. Wrought copper products generally have better mechanical properties than cast products made from the same material, with a more dense internal structure.

The process of forging copper typically involves the following steps:

Forged copper is used in various applications across industries, including:

| Grade | Specification(mm) | State | Hardness(HB) | Tensile strength (N/mm~2) | Elongation(%) | Volume resistivity20℃ (Ωmm2/m) | Reference standard | ||

| Thickness | width | ||||||||

| Cu-ETP CW004A Cu-OF CW008A | Customized | Customized | H035 | 35-65 | / | / | ≤0.017241 | DIN-EN 13601 | |

| H065 | 65-90 | / | / | ≤0.01777 | |||||

| R230 | / | ≥230 | ≥10 | ||||||

| CuAg0.04 CW011A CuAg0.07 CW012A CuAg0.10 CW013A | Customized | Customized | H035 | 35-65 | / | / | ≤0.017241 | ||

| H065 | 65-90 | / | / | ≤0.01777 | |||||

| R230 | / | ≥230 | ≥10 | ||||||

| Precision of piece: | General purpose or customized | ||

| Package: | General purpose or customized | ||

| Quality standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS; | ||

| Drawing format: | JPEG,PDF,AI,PSD,DWG,DXF,IGS,STEP; | ||

| Products certification: | ISO9001:2008, CE, RoHS, SGS; | ||

| Dimension: | Customizable | ||

About us:

Jiangyin Electric Alloy Co., Ltd., formerly known as Jiangyin Electric Alloy Factory, was established on June 12, 1985. It is mainly engaged in the research and development, production, and sales of high-speed rail supporting products. Its main products are copper alloy deep processing products, including railway contact wires, railway load-bearing cables, copper alloy busbars, and other copper components.

Since its establishment, the company has been committed to providing customers with high-quality copper alloy products and services with advanced management systems, strong research and development capabilities, excellent product quality, and comprehensive services.

It has successively cooperated with railway bureaus under the Ministry of Railways, such as Shanghai, Guangzhou, Beijing, Zhengzhou, Chengdu, and other railway bureaus; Locomotive and motor production enterprises of the Ministry of Railways, such as CRRC and national motor and electrical appliance production enterprises, as well as well-known domestic and international enterprises such as Xiangtan Electric, Dongfang Electric, Schneider Electric, Siemens, ABB, GE, etc., have established strategic cooperative relationships and become a licensed supplier of copper and copper alloy stranded wire and contact wire for the China Railway Group Electric Gasification Bureau.

We provide technical support and services for copper contact wire, including:

Packaging and Shipping: