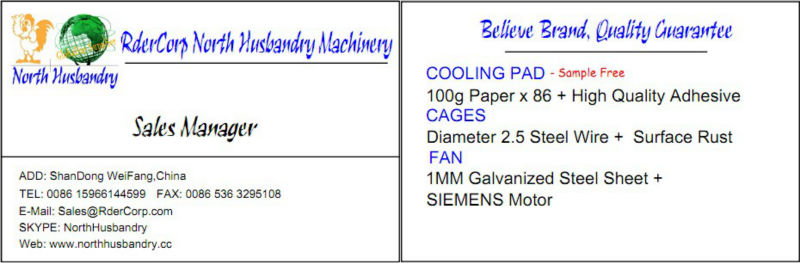

RderCorp North Husbandry Machinery |

Push-pull Centrifugal Ventilation Fan

Model | Blade (MM) | Frequency (HZ) | Motor Speed (R/MIN) | Capacity (CBM/H) | Power (HP) | Noise (DB) | Voltage (V) | Frame Size (MM) | Zinc Thickness |

NH-1000 | 910(36'') | 50/60 | ≥1400 | 35000 | 1.0 | ≤64 | 380/220 | 1000x1000x450 | 180g/m2 |

NH-1380 | 1270(50'') | 50/60 | ≥1400 | 48000 | 1.5 | ≤64 | 380/220 | 1380x1380x450 | 180g/m2 |

push-pull centrifugal fan details

1, Frame: frames are made of galvanized board, thickness 1.0mm, galvanizing layer 180g/square meter.

2, Blade: 6 pieces, material 430/201 stainless steel, mirror face.

3, Impeller, casting aluminum alloy impeller.

4, Bearing of impeller :permanently sealed bearing, size 633313.

5, Venture: galvanized board, thickness 1.0mm.

6, Blade tip clearance: 25mm, mirroe face.

7, Inlet wind protecting net: spraying paint steel wire, thickness 2.8mm.

8, Electrical motor: aluminum alloy frame motor, 380V/220/415V, 1.1KW/0.75KW(1.5HP/1HP), 50HZ/60HZ, 3PH/Single Phase, 4-pole speed, 1410r/m, IP55, class F, efficiency 90%, top/foot mounted,

9, Motor bearing, :national grade.

10, Belt: V-belt and A-belt (Made-in-China and Japan brand Mitsuboshi).

11, Shutters, galvanized board, 0.8 mm thickness while the middle piece thickness 1.0mm. Galvanizing layer ,120g/square meter.

12, Opening system, nylon material, brown color and black color.

13, Rivets: aluminum alloy and stainless steel rivets.

14, Cable: 1 meter long, strong robber wire.

15, Tensioner: plastic or aluminum.

16, Warranty : 1 year for the whole machine.

Other advantahes:

A). Fans parts are manufactured by digital machines and precision system is assisted by computers, which maximizes the effectiveness of the fan.

B), Ten strict testing procedures to keep good quality of the fan: 1), airflow test; 2), noise test; 3), libration test; 4), drive concentric test; 5), blade RPM test; 6), electric current test; 7), whole machine efficiency test; 8), dynamic balance test; 9), the thickness of the galvanized sheet test; 10), the size of the spare parts test.

>>>www.northhusbandry.cc<<<