Active Member

|

[China]

Address: No. 1 Damawan, Jiaodong, Jiaozhou, Qingdao, China

Contact name:Derek

QINGDAO PERMIX MACHINERY CO., LTD |

|

Ceramic Materials Counter Current Mixer No Hidden Corners PMC1250

1.APPLICATION INDUSTRIES

1. Concrete

Precast concrete: various block bricks, sleepers, track slabs,

metro tunnel segments, PC components, PCCP water pipe,

Lightweight aggregate concrete: Light soil cement

slurry,polyphenylene granule cement slurry, other lightweight

aggregate concrete,

High Performance ready-mixed concrete: Self-leveling mortar, etc.

2. Pot Clay,

3. Ceramics,

4. Glass Raw Material,

5. Casting materials: Sand mixing, casting coatings,

6. Refractories: Unshaped refractories, refractory bricks,

Others

2. Mixer advantages

The machine has the dual advantages of independent operation and

the simple concrete mixing plant combined with PLD series batching

machines. It can also provide matching hosts for the mixing

station. It is suitable for all kinds of large, medium and small

prefabricated component plants and highways and bridges. The product design structure is reasonable, the layout is novel,

and it is easy to use and maintain. Water conservancy, docks and other industrial and civil

construction projects are ideal for the host of concrete mixing

plants. Users can use dump trucks and mixer trucks for their own

use. At the same time, they can also be restructured according to

the special requirements of users to meet their needs.

3. The Skip Hopper

The feeding door automatically opens when feeding, and closes when

the hopper begins to descend. The device effectively prevents the

dust overflow the trough during the mixing to protect the

environment.

Skip hopper can be chosen according to the requirements of

customers.

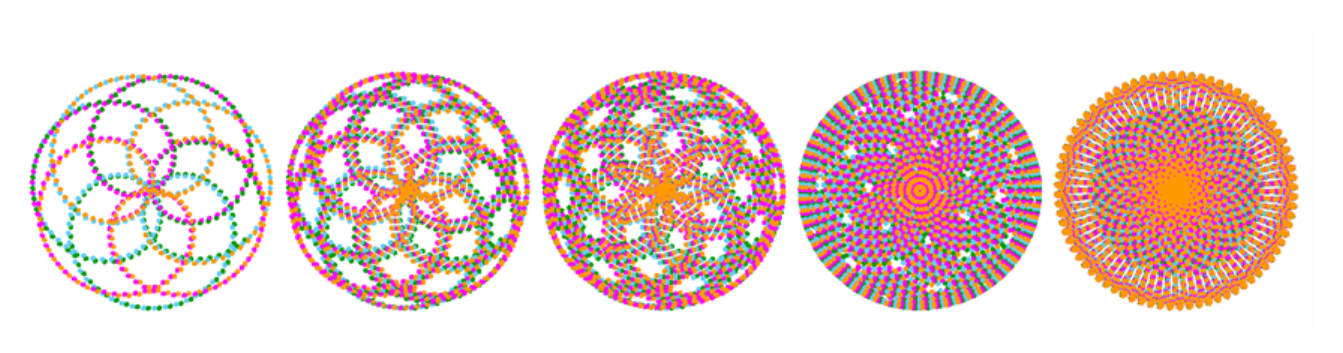

Principle of Motion: Mixing with no hidden corners in the mixing

pan by installing mixing tools and scraper tools on a specially

designed drive system.

The mixing track as follows.

| Technical Specification | ||||||||||||||

| ITEM/(PMC) | PMC 50 | PMC 100 | PMC 150 | PMC 250 | PMC 330 | PMC 500 | PMC 750 | PMC 1000 | PMC 1250 | PMC 1500 | PMC 2000 | PMC 2500 | PMC 3000 | PMC 4000 |

| Feeding Capacity (L) | 75 | 150 | 225 | 375 | 500 | 750 | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 6000 |

| Output Capacity (L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Feeding Weight (kg) | 120 | 240 | 360 | 600 | 800 | 1200 | 1800 | 2400 | 3000 | 3600 | 4800 | 6000 | 7200 | 9600 |

| Mixing Power (kw) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 |

| Discharging Power (kw) | Pneumatic Discharge(Hydraulic Discharge Optional) | 3 | 3 | 3 | 4 | 4 | 4 | 4 | ||||||

| Mixing Star*Blade | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*3 | 2*2 | 2*2 | 2*2 | 3*2 | 3*3 | 3*3 | 3*3 |

| Side Scraper | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Discharge Scraper | - | - | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Weight (kg) | 750 | 1000 | 1300 | 1500 | 2000 | 2400 | 3900 | 5500 | 6000 | 6500 | 9200 | 11000 | 12000 | 17500 |

| Lifting Power (kw) | - | - | - | 3 | 4 | 4 | 7.5 | 11 | 11 | 15 | 18.5 | 22 | 30 | - |

| Dimension (L*W*H) mm | 950* 790* 1200 | 1664* 1453* 1487 | 1670* 1460* 1620 | 1860* 1650* 1780 | 1870* 1870* 1855 | 2230* 2080* 1880 | 2580* 2340* 2195 | 2891* 2602* 2237 | 3058* 2756* 2395 | 3223* 2902* 2470 | 3625* 3230* 2695 | 3893* 3550* 2875 | 3893* 3550* 3085 | 4594* 4150* 3634 |