Wuxi Techwell Machinery Co., Ltd |

|

Verified Suppliers

|

|

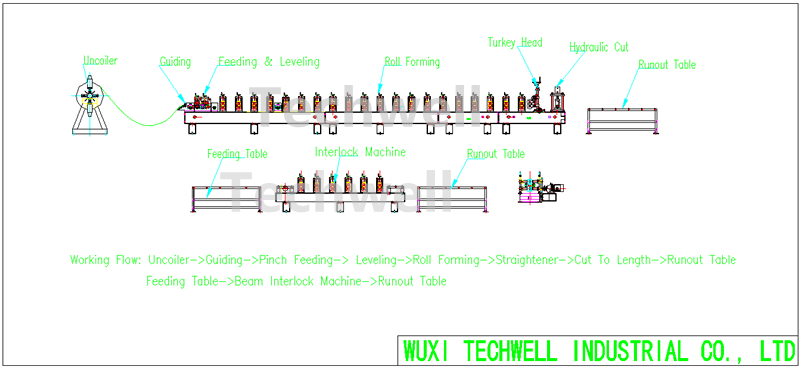

Storage Racking Box Beam Production Line is for making the racking load beam section profiles.

Introduction of Rack Beam Roll Forming Machine

Racking system box beam roll forming machine is designed to produce various sizes of box beam sections as the client's profile drawing or requirements. The standard material thickness is 1.5-2.0mm, or upto 2.5mm.

And the Whole box beam roll former is made up with 3 Ton Uncoiler, feeding & leveling, main roll forming, hydraulic cutting, hydraulic station, plc control board, support tables and box beam interlock machine.

Box Beam Profiles

Main Specifications of Upright Rack Roll Forming Machine

| Main Specifications of Box Beam Roll Forming Machine | ||||

| No. | Item | Parameter | Remark | |

| 1. | Suitable Material | Type | JIS G3101 SS400-SS540 | |

| Thickness | 1.5-2.0mm | |||

| Width | Based on profile | |||

| 2. | Profile Size | C100 * 50mm C125 * 50mm

| ||

| 3. | Line Speed | 0-20m/min. | excluding cut time | |

| 3. | Forming Station | ≈ 14 | ||

| 5. | Shaft Diameter | Φ70mm | Roll forming | |

| Φ75mm | Beam lock machine | |||

| 6. | Roller Material | GCr15 bearing steel, HRC 58-62° and roller surface with hard chrome ≥ 0.05mm | ||

| 7. | Drive Type | Chain Drive | ||

| 8. | Forming Structure | Welded wall structure | ||

| 9. | Motor Power | Main Machine | ≈ 11KW + 3KW | |

Hydraulic Stations

| ≈ 5.5KW | For cutting | ||

| 10. | Total Power | ≈ 19.5KW | ||

| 11. | Electric Source | AC380V, 3 Phase | Or Customized | |

| 12. | Main Machine color | Blue | Or Customized | |

The Working Flow of Step Beam Forming Machine

Uncoiler --> Feeding & Leveling --> Roll Forming --> Cutting --> Seam lock Machine -->Run-out Tables

Main Components of Upright Rack Production Line

| Hydraulic Decoiler | 1 Unit |

| Leveling | 1 Unit |

| Main Roll Forming Machine | 1 Unit |

| Hydraulic Cutting | 1 Unit |

| Seamlock Machine | 1 Unit |

| Electric Control System | 1 Unit |

| Run out Table | 1 Unit |

More Upright Rack Forming Machine Pictures

Contact TECHWELL

| Company | Wuxi Techwell Machinery Co.,Ltd | |

| Website | www.wxtechwell.com | |

| www.cold-rollformingmachine.com | ||

| www.roofrollformingmachine.com | ||

| Tel/Fax | 0086-510-83133431 | |

| Mobile/Whatsapp | 0086-18018304331 | |

| E-Mail: | monica@wxtechwell.com | |

| Youtube Video | www.youtube.com/wxtechwell | |