Wuxi Techwell Machinery Co., Ltd |

|

Verified Suppliers

|

|

Steel Silo Corrugated Wall Sheet Roll Forming Machine for Silo Side Panel

A). Basic Introduction of Main Components

1). Forming machine: making the material bend and initial machine-shaping, meanwhile, it will bend the material to the silo required radius of curvature.

2). Bending machine: it will roll cooperate with good molding materials bender seaming together

3). Load bearing support: Given the right diameter of silo. Lifting of the steel silo enclose the top of load bearing support rollers, it can support the spiral rising silo.

4). Decoiler: Moving steel coils that put on the decoiler, making steel coils can into forming machine successfully.

5). Join frame: Joining the load bearing support, locking the required diameter of soil, making the load bearing support stable working.

B). Main Specifications of Steel Silo Roll Forming Machine

C). Working Flow

Loading coil car -> Uncoiler -> guiding device -> feeder -> leveller -> shear roll former -> hydraulic press -> curving -> hydraulic cutting -> stacker -> PLC control

D). Comparison with Common Silo

1. Large capacity

One single-silo capacity is up to 17,000 tons with comprehensive configurations to meet customers’ different requirements.

2. High accuracy

Complete advanced processing equipment and technology are introduced from USA to effectively ensure working accuracy and reduce damage to galvanized layer.

3. Less residues

External installable stiffeners contribute to less grain residues on silo walls.

4. Detachable and movable

With standardized and modularized production, components and parts have a high standardization and good interchangeability, thus can be partially replaced or completely transferred.

E). Our Competitive Advantages

Professional Team Support

High Quality

Reasonable Price

Good aftersale Service

1 Year Warranty

More Than 10 Years Experience

F). More Machine Pictures

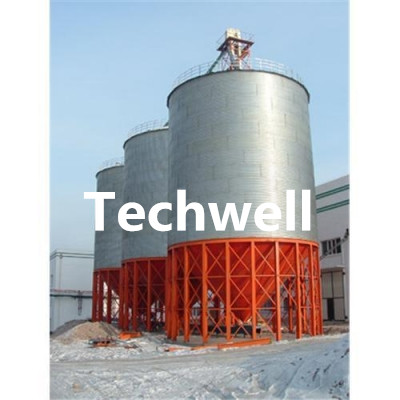

G). Output Product Pictures

H). Applications

Steel silo corrugated sheet, steel silo corrugated panel, silo wall sheet, silo corrugated wall sheet, silo wall panel, silo corrugated wall panel, silo side panel, steel corrugated sheet, steel corrugated wall panel, steel corrugated panel

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available.

Q: Once we've bought a machine from you, are you able to supply us with material?

A: We can assist you in finding the appropriate materials to suit your machine.

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

Q: What size decoiler can you supply us with?

A: From 5-ton decoiler to a 25-ton motorised hydraulic decoiler.

Q: Do you have a warranty on your machines?

A: One year warranty excluding electrical components.

Q: Do you have instruction manuals?

A: We provide you with instruction manuals, electricity layouts, civil requirements, and machine drawings.

Q: Once a machine arrives at our factory what happens then?

A: We will send you a technician or engineer that will commission and install your machine, with training for your staff if required at a separate fee.

Q: What do I need to offload my machine from the container?

A: You are not responsible for the offloading of your machinery, and it is recommended that you use a reputable rigging company.

Q: My current machine rollers need to be replaced. Would you be able to assist me?

A: Yes. Send us your profile and specifications then we will manufacture the rollers for you.

Q: Do we receive any updates while machine is in the manufacturing process?

A: Yes.Regular updates on progress will be sent to you.

| Item | Contact Methods |

| Contact Person | Lemon |

| E-mail / Skype | sales@wxtechwell.com |

| Tel / Whatsapp/ IMO | +86-15861597732 |

| Website | https://www.wxtechwell.com |