Jiangsu Co-effort Mechanical&Electrical Technology Co., Ltd |

|

Automatic Wall Panel Roll Forming Corrugated Roof Sheet Making Machine

Working Process Flow of Roll Forming Machinery

Decoiler→ Feeding → Roll forming → Hydraulic cutting → Output table

Roll Forming Machine Technical Parameter Requirements

| Main moter power | 4 kw |

| Hydraulic station power | 3 kw |

| Shearing die | Gr12 |

| Sprocket | P-25.4 |

| Transmission mode | Chain |

| The bearing capacity of manual decoiler | 5 tons |

| Sprocket chain specifications | 0.6 inch |

| Roller station | 10-15 rows |

| Main frame structure | 350H steel |

| Diameter of principal axis | 75mm |

| Material of roller | 45#steel hard chrome Hardness HR55°—57° Solid shaft |

| Processing speed | 10-15m/min |

| Thickness | 0.2-0.7mm |

| Feeding material width | 600mm-1250mm |

| 1. | Dimension | 5800*1600*1400mm |

| 2. | Weight | 7000KGS |

| 3. | Motor Power | 7.5KW*2 sets |

| 4. | Hydraulic Power | 2.2KW |

| 5. | Voltage | 380V/50HZ/3PH (according to your requirements) |

| 6. | Forming Stations | 13 |

| 7. | Forming Speed | 8-14m/min |

| 8. | Effective Width | 300mm,400mm,500mm |

| 9. | Material of Width | 470mm,575mm,680mm |

| 10. | Material of AL-Mg-Mn,Galvanized Sheet Thickness | 0.4-1.0mm |

| 11. | Material of Colored Prepainted Sheet Thickness | 0.5-0.8mm |

| 12. | Material for All Roller | high grade no.45 forged steel,plated hard chrome and polished the rollers |

Roof Panel Roll Forming Machine Components

| Item | Name | Qty |

| 1 | Manual Decoiler | 1 set |

| 2 | Feeding platform with hand cutting system | 1 set |

| 3 | Main forming system | 1 set |

| 4 | Hydraulic cutting system | 1 set |

| 5 | Hydraulic pump station | 1 set |

| 6 | Electrical motor | 1 set |

| 7 | PLC control system | 1 set |

| 8 | Touch screen operation | 1 set |

| 9 | Finished products receive table | 1 set |

| 10 | Safety shield(optional) | 1 set |

Technical Parameters of Roof Panel Roll Forming Machinery

| NO | Item | Description |

| 1 | Product' sizes | According to customer's request |

| 2 | Processing material | GI |

| 3 | Processing thickness | 0.6-1.2mm |

| 4 | Main motor power | 7.5kw |

| 5 | Power of hydraulic station | 7.5kw |

| 6 | Quantity of roller stations | 20 |

| 7 | Production speed | Approximate 15-25 m/min |

| 8 | Diameter of shafts | Φ80mm |

| 9 | Material of rollers | Cr12 steel with vacuum heat treatment HRC57°-60° |

| 10 | Material of shafts | 45# steel quenched and tempered |

| 11 | Material of cutting blades | Cr12 mould steel with quenched treatment |

| 12 | Size of machine | Approximate 7500mm(L)×160mm(W)×1800mm(H) |

| 13 | Theoretical weight | Approximate 7000KGS |

| 14 | Driven method | Chain transmission |

| 15 | Brand of PLC | Yaskawa |

| 16 | Cut mode | Hydraulic profile cutting |

| 17 | Power supply | 380V 50HZ 3Phases or at buyer's requirement |

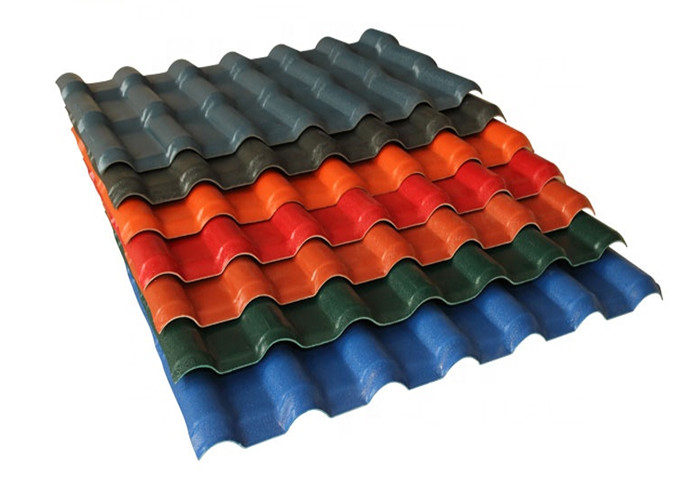

Our Roof Panel Roll Forming Machine Can Produce All Kinds of Color Steel Tile