Jiangsu Co-effort Mechanical&Electrical Technology Co., Ltd |

|

15m / Min Cold-Rolled Steel Storage Rack Roll Forming Machine

1. With the popularization of steel structure, more and more special-shaped steel has been widely used in various fields and received more and more attention.

2. After feeding, forming and after forming, the special-shaped

metal plate roller press has smooth and beautiful appearance,

uniform paint pattern, high strength and durability. It is widely

used in industrial and civil buildings, such as workshop,

warehouse, locomotive shed, hangar room, gymnasium, exhibition

hall, theater and other surface walls. Its components include:

machinery, PLC computer control system, hydraulic pump station

system, automatic back shear system equipment. The stroage rack

roll forming machine consists of machine, PLC computer control

system, hydraulic pump station system and automatic cutting system.

Requirements of Rack Shelf Roll Forming Machine

| No. | Item | Specification |

| 1 | Can Formed Material | PPGI,GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.8mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 6000mmx1600mmx1400mm |

| 8 | Speed | 8-15m/min |

| 9 | Diameter of shaft | 75mm |

| 10 | Weight of the Machine | 3000-3500KGS |

| 11 | Material of rollers | C45 steel quenched and chromed |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC | Siemens or Delta or Mitsubushi |

| 14 | Total power (kw) | 9.5kw |

| 15 | Power of hydraulic system | 5.5kw |

| 16 | Power of main molding core | 4kw |

| No. | Item | Description |

| 1 | Rolling speed | 0-15m/min(not include cutting time) |

| 2 | Rolling thickness | 2.5-3mm |

| 4 | Un coiler | 3 TON hydraulic decoiler |

| 5 | The material width | based on profile drawing |

| 6 | Material | GI |

| 7 | Roller stations | 18 stations( base on final design) |

| 8 | Leveling stations | 7 stations |

| 9 | Punching machine | 125T pneumatic punching machine |

| 10 | Roller material | CR12, 58-62,HRC hardness and chrome plated surface |

| 11 | Shaft diameter | 45# forge steel ¢76mm |

| 12 | Maim motor power | 18.5kw |

| 13 | Hydraulic station power | 7.5KW |

| 14 | Hydraulic pressure | 25Mpa |

| 15 | Material of cutting | Cr12 with heat treatment 58-60° |

| 16 | Tolerance | 3m+-1.5mm |

| 17 | Electric source | 380V, 50HZ,3 phase |

| 18 | Way of driving | By gear box |

| Upright Roll Forming Making Machine | ||

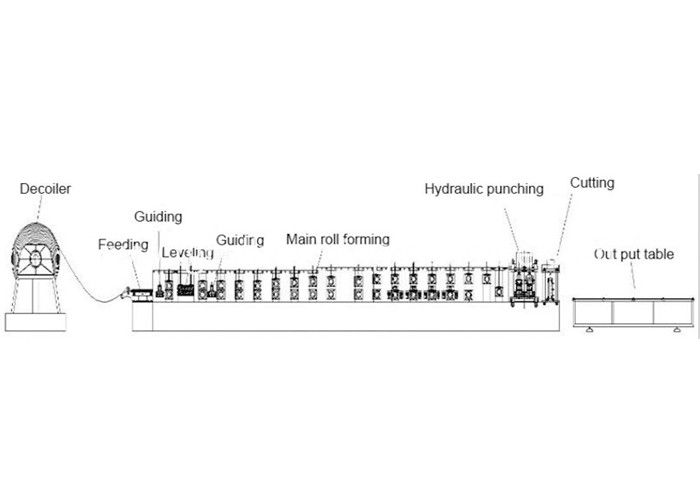

Shelf Roll Forming Machine Woring Process

Decoiler ----- Leveling (Straightening) ----- Roll Forming -----

Punching ----- Cutting ----- Unloading

Or

Decoiler ----- Leveling (Straightening) ----- Punching ----- Roll

Forming ----- Cutting ----- Unloading

Photos of Storage Rack Shelves Roll Forming Machine