Active Member

|

[China]

Address: Tuanjie Industrial Zone, Xin'an Town, Bazhou City, Langfang City, Hebei Province (in Yangzi Management Institute)

Contact name:Zhang

Shenyang Jingcheng Electromechanical Equipment Co., Ltd. Bazhou branch |

|

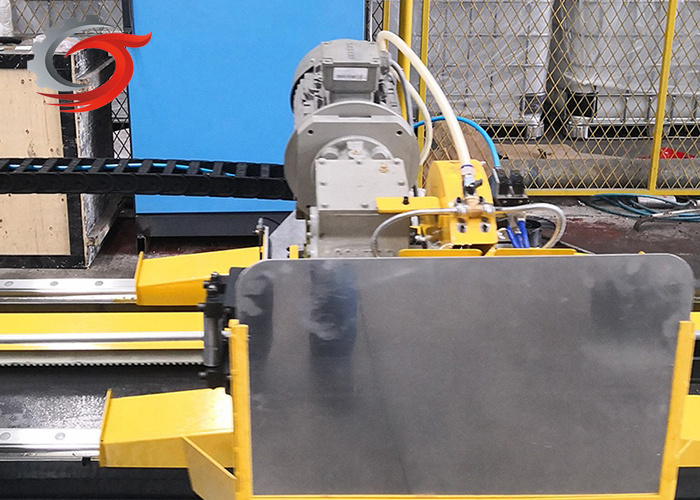

High Precision CNC Flying Cold Saw Pipe Cutting Machine High Speed Cold Cutting Pipe Mill

Introduction

Product for cutting steel tubes into burr-free fly-cold saws with a length tolerance of +/- 0.5 mm. Its purpose is to cut pipes to shorter lengths. This machine is used to cut smaller pipe lengths that were not previously possible with in-line mills.

| material | Q195 Q235 SPCC | |

Cutting range | Round tube:MAX53mm | thick:0.5~2.5mm |

| Square tube:MAX40×40mm | thick:0.5~2.5mm | |

| Operation height | 750mm | |

| Cutting burr height | Max:0.25mm; | |

| Mechanical length | 4420*1280*1280mm(as per final drawing) | |

Motor list | Drive:15KW | PHASE servo motor |

| feed: 1.8KW | PHASE servo motor | |

| saw: 11KW | Siemens AC motor | |

| Linear guide | Hiwin Chinese Taiwan | |

| Gear rack | KH from Chinese Taiwan | |

| Carriage protection | Safety bumpers for carriage are equipped at both ends | |

| Equipment document | User’s manual & electrical diagram | |

Features

1. The sawing method of cold milling is adopted, and the sawing

process generates little heat, avoiding the change of internal

stress and material structure at the incision section.

2. The quality of the cut end face of the workpiece processed by

the high-speed steel cold cutting saw is good

3. The service life is long. The saw blade grinding machine can be

used to grind the teeth for many times. The service life of the

polished saw blade is the same as that of the new saw blade.

Improve production efficiency and reduce costs.

our service

1. Professional pre-sales consultation and after-sales service to

help you find the best solution

2. Discuss technical details with our professional engineers

3. Strictly control the quality and production plan of the cold

flying saw. You will be kept informed of any progress

4. Check the cold flying saw before shipment

5. After the warranty period, spare parts are provided at cost

6. Professional engineers help you increase production, reduce

waste and reduce costs

7. Control the production progress and quality of the machine, and

provide you with detailed information in time